DIDW Centrifugal Fan 455 MM X 455 MM

DIDW Centrifugal Fan 455 MM X 455 MM Specification

- Max Pressure

- 80 mm WG

- Flow Rate

- 3000-3500 m/h

- Pressure Range

- 50-80 mm WG

- Life Span

- Up to 10 Years (with regular maintenance)

- Motor Power

- 2 HP

- Output Power

- 1.5 kW

- Power

- 1.5 kW

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 3000-3500 CFM

- Pressure

- 50-80 mm WG

- Application

- HVAC Systems, Industrial Ventilation

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- Approx. 45 kg

- Dimension (L*W*H)

- 455 mm x 455 mm x 400 mm

- Color

- Blue

DIDW Centrifugal Fan 455 MM X 455 MM Trade Information

- Minimum Order Quantity

- 2 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Manipur, Pondicherry, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Lakshadweep, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Uttar Pradesh, Gujarat, Central India, Chhattisgarh, All India

About DIDW Centrifugal Fan 455 MM X 455 MM

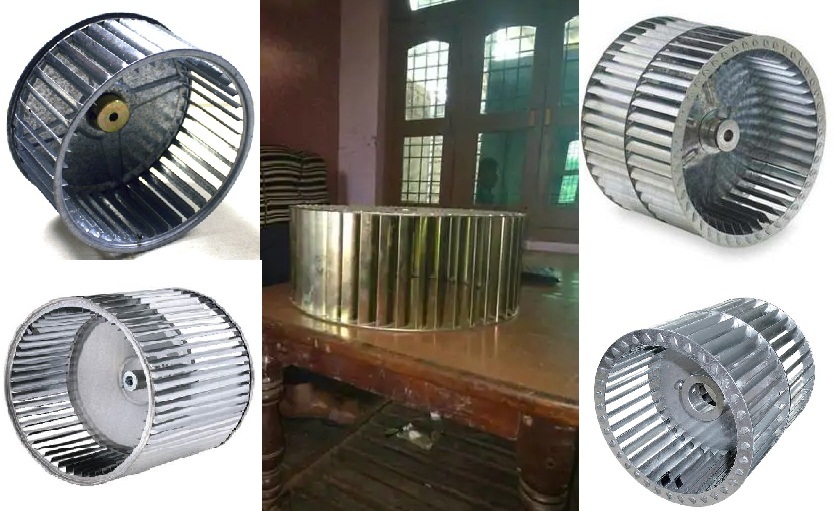

DIDW Centrifugal Fan 455 MM X 455 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 60 | DP 18 18 | 455 X 455 X 365 | 18 X 18 | 30 MM,35 MM,& 1.5 | AL. / GI. |

Superior Construction for Longevity

Built using galvanized steel impellers and a mild steel frame, the DIDW Centrifugal Fan is engineered to withstand demanding industrial conditions. The epoxy-coated finish protects against corrosion and wear, ensuring a service life of up to 10 years with regular maintenance.

Optimized Performance and Efficiency

With a static efficiency of up to 70%, this centrifugal fan effectively moves air at capacities ranging from 3000 to 3500 CFM. Its forward curved blades and robust belt drive system help maximize airflow while maintaining operational noise below 80 dB.

FAQs of DIDW Centrifugal Fan 455 MM X 455 MM:

Q: How is the DIDW Centrifugal Fan typically installed?

A: This fan is base mounted, allowing for secure attachment to various surfaces in HVAC or industrial ventilation setups. Professional installation is recommended to ensure correct alignment and optimal performance.Q: What applications is this centrifugal fan suitable for?

A: The fan is ideal for use in HVAC systems, industrial ventilation, and environments requiring consistent high-capacity airflow. It can function efficiently in spaces demanding reliable air circulation and dust control.Q: When should the fan undergo regular maintenance?

A: It is advised to inspect and maintain the fan periodicallyat least every six months or as per usage intensity. Regular checks help maintain its performance, reduce noise levels, and extend its operational life up to 10 years.Q: Where can this fan be used given its construction and rating?

A: Thanks to its robust build and Class F insulation, the DIDW Centrifugal Fan performs reliably in ambient temperatures ranging from -10C to 60C. It suits both indoor and certain sheltered outdoor industrial locations.Q: What is the process for switching the direction of rotation?

A: The fan supports clockwise and counter-clockwise rotation, a feature that can be set during installation or adjustment. Specific wiring according to the motor instructions is needed for changing the rotation direction safely.Q: What are the benefits of using a belt-driven, forward-curved blade design?

A: The belt-driven mechanism offers smoother operation and efficient power transmission. Forward curved blades maximize air delivery at lower noise levels, improving comfort and reducing energy costs in ventilation systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 228 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Pressure : Other, 320 Pa (Static Pressure)

Output Power : 0.75 kW

Power Source : Other, Electric

DIDW Centrifugal Fan 160 MM X 178 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2800 RPM

Pressure : Other, 250400 Pa

Output Power : 120 W

Power Source : Other, Electric

DIDW Centrifugal Fan 250 MM X 203 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Motor Speed : 2880 RPM

Pressure : Other, Upto 60 mmWG

Output Power : 0.75 kW

Power Source : Other, Electric

DIDW Centrifugal Fan 610 MM X 530 MM

Price 22000.00 INR

Minimum Order Quantity : 1 Piece

Motor Speed : 1440 RPM

Pressure : Other, Up to 800 Pa

Output Power : 5.5 kW

Power Source : Other, Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS