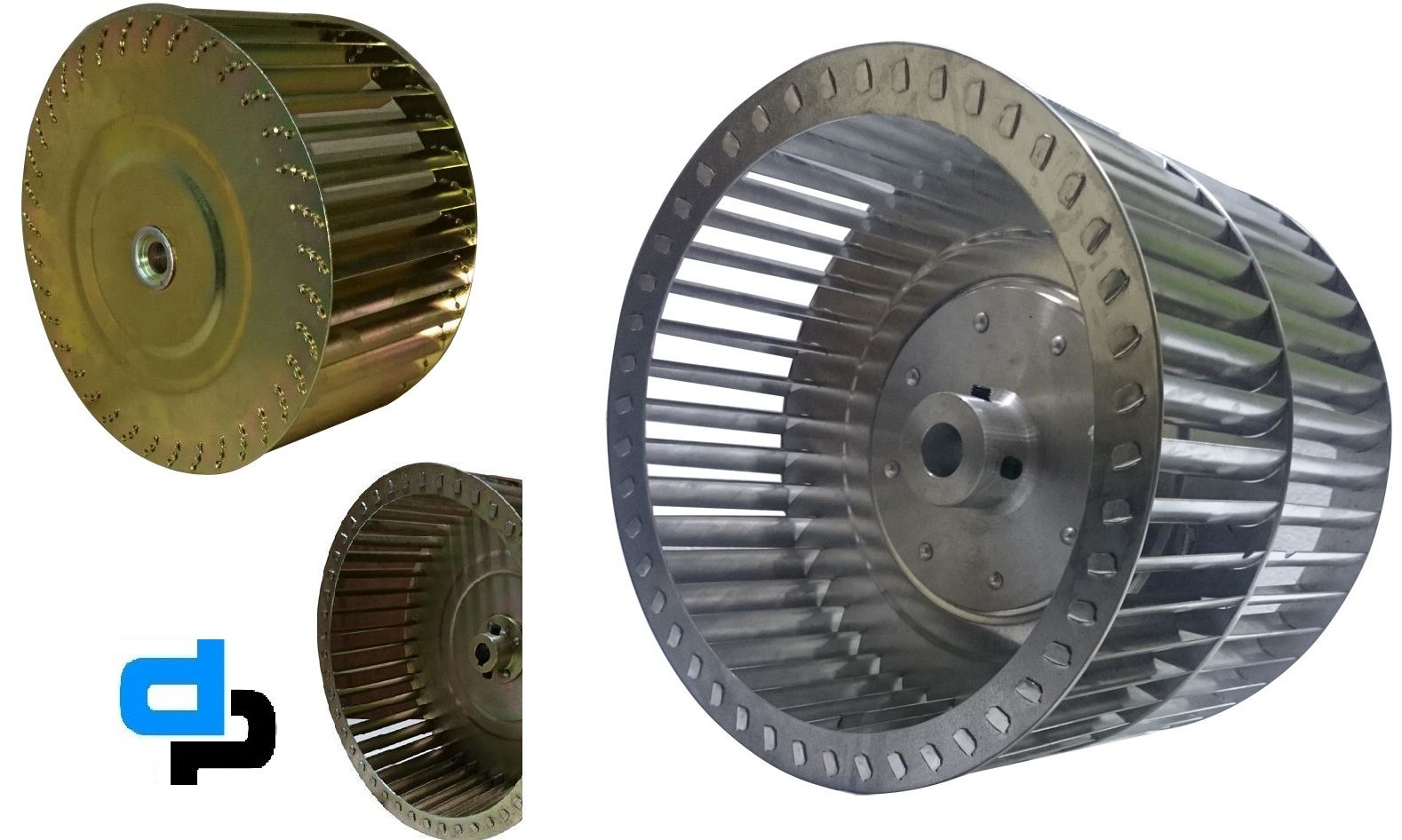

DIDW Centrifugal Fan 160 MM X 228 MM

DIDW Centrifugal Fan 160 MM X 228 MM Specification

- Max Pressure

- 260 mmWG

- Motor Power

- 0.5 HP

- Output Power

- 370 W

- Flow Rate

- 600 m/h

- Pressure Range

- Up to 260 mmWG

- Life Span

- More than 5 Years

- Power

- 0.37 kW

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel / Powder Coated

- Capacity

- 600 m/hr

- Pressure

- 260 mmWG

- Application

- Air ventilation, HVAC, Industrial ventilation systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 75 dB

- Power Source

- Electric

- Voltage

- 230 V AC

- Weight

- Approx 8 kg

- Dimension (L*W*H)

- 160 mm x 228 mm

- Color

- Blue

DIDW Centrifugal Fan 160 MM X 228 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Andaman and Nicobar Islands, Chandigarh, Himachal Pradesh, Uttarakhand, Daman and Diu, Nagaland, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Dadra and Nagar Haveli, Lakshadweep, Maharashtra, Haryana, Delhi, Gujarat, Uttar Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 160 MM X 228 MM

DIDW Centrifugal Fan 160 MM X 228 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 15 | DP 65 90 | 160 X 228 X 135 | 6.5 X 9 | 12.70 (1/2'') & 15 MM | AL. / GI. |

Robust Construction for Longevity

This centrifugal fan features a heavy-duty steel frame with a corrosion-resistant, powder-coated blue finish. The sealed ball bearings and high-quality materials provide resistance to harsh industrial conditions, ensuring a life span exceeding five years under recommended usage. Its design assures consistent operation with minimal maintenance.

Efficient Performance and Versatility

With a flow rate of 600 m/h and a maximum pressure of 260 mmWG, this fan efficiently meets ventilation demands in industrial, HVAC, and commercial settings. Direct-drive configuration with a forward-curved impeller ensures high efficiency, reduced noise (below 75 dB), and reliable airflow for varied environments.

User-Friendly and Safe Operation

Operating at 230 V AC and 2800 RPM, the fans motor is IP44 protected and Class F insulated, providing safe, continuous performance in temperatures from -10C to 55C. The base/foot mount allows straightforward installation, while the side discharge ensures flexible integration into existing air systems.

FAQs of DIDW Centrifugal Fan 160 MM X 228 MM:

Q: How is the DIDW Centrifugal Fan 160 MM X 228 MM installed?

A: This centrifugal fan is designed with a base/foot mounting type, allowing easy installation on stable surfaces. It is typically fixed using bolts or anchors, securing the unit in place for optimal, vibration-free operation in ventilation and HVAC systems.Q: What applications are ideal for this centrifugal fan?

A: The fan is well-suited for use in air ventilation, HVAC systems, and industrial ventilation setups where efficient air movement is required. Its robust design makes it ideal for factories, workshops, commercial buildings, and environments with moderate to harsh operating conditions.Q: When should this fan be maintained or serviced?

A: Routine checks every six months are recommended to ensure optimal operation. Clean the fan and inspect bearings for any signs of wear. The sealed ball bearings require minimal maintenance, contributing to extended operational life and reliability.Q: Where can this fan be used given its temperature and protection ratings?

A: With an operational temperature range of -10C to 55C and a motor protected to IP44 standards, the fan is suitable for most indoor and sheltered outdoor industrial environments, provided there is no direct exposure to heavy water spray or extreme contaminants.Q: What benefits does the forward curved impeller design offer?

A: The forward curved impeller is engineered for high airflow at lower noise levels, making the fan efficient for larger air volumes with moderate pressure demands. This design ensures quieter operation, making it highly suitable for both industrial and commercial installations.Q: How does the fans construction enhance its durability?

A: Built from heavy-duty steel and finished with corrosion-resistant, powder-coated materials, the fan is resilient against wear, rust, and harsh operational conditions, ensuring longevity and stable performance across its lifespan.Q: What is the process to integrate this fan into an existing ventilation system?

A: Integration involves securing the fan using its base/foot mount, connecting the power supply (230 V AC), and aligning the side air discharge with the duct or ventilation path. Proper electrical and airflow connections ensure efficient operation within your ventilation infrastructure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 203 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Max Pressure : 60 mmWG

Power Source : Other, Electric

Motor Power : 1 HP

DIDW Centrifugal Fan 530 MM X 380 MM

Price 18500 INR

Minimum Order Quantity : 2 Pieces

Material : other , Mild Steel

Max Pressure : 400 mm WG

Power Source : Other, Electric

Motor Power : 2.2 kW

DIDW Centrifugal Fan 300 MM X 254 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Max Pressure : 130 mm WG

Power Source : Other, Electric

Motor Power : 3 HP

DIDW Centrifugal Fan 180 MM X 178 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Galvanized Steel

Max Pressure : 400 Pa

Power Source : Other, Electric

Motor Power : 0.18 HP

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS