DIDW Centrifugal Fan 160 MM X 200 MM

DIDW Centrifugal Fan 160 MM X 200 MM Specification

- Flow Rate

- Up to 1500 m3/h

- Motor Power

- 1 HP

- Power

- 0.75 kW

- Life Span

- Up to 10 years

- Pressure Range

- 40-150 mmWG

- Output Power

- 0.75 kW

- Max Pressure

- 150 mmWG

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1500 CFM

- Pressure

- 40-150 mmWG

- Application

- Air Ventilation, HVAC, Industrial Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Less than 70 dB

- Power Source

- Electric

- Voltage

- 220-240 V AC

- Weight

- Approx. 7 kg

- Dimension (L*W*H)

- 160 mm x 200 mm

- Color

- Silver Grey

DIDW Centrifugal Fan 160 MM X 200 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Karnataka, North India, Kerala, Central India, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 160 MM X 200 MM

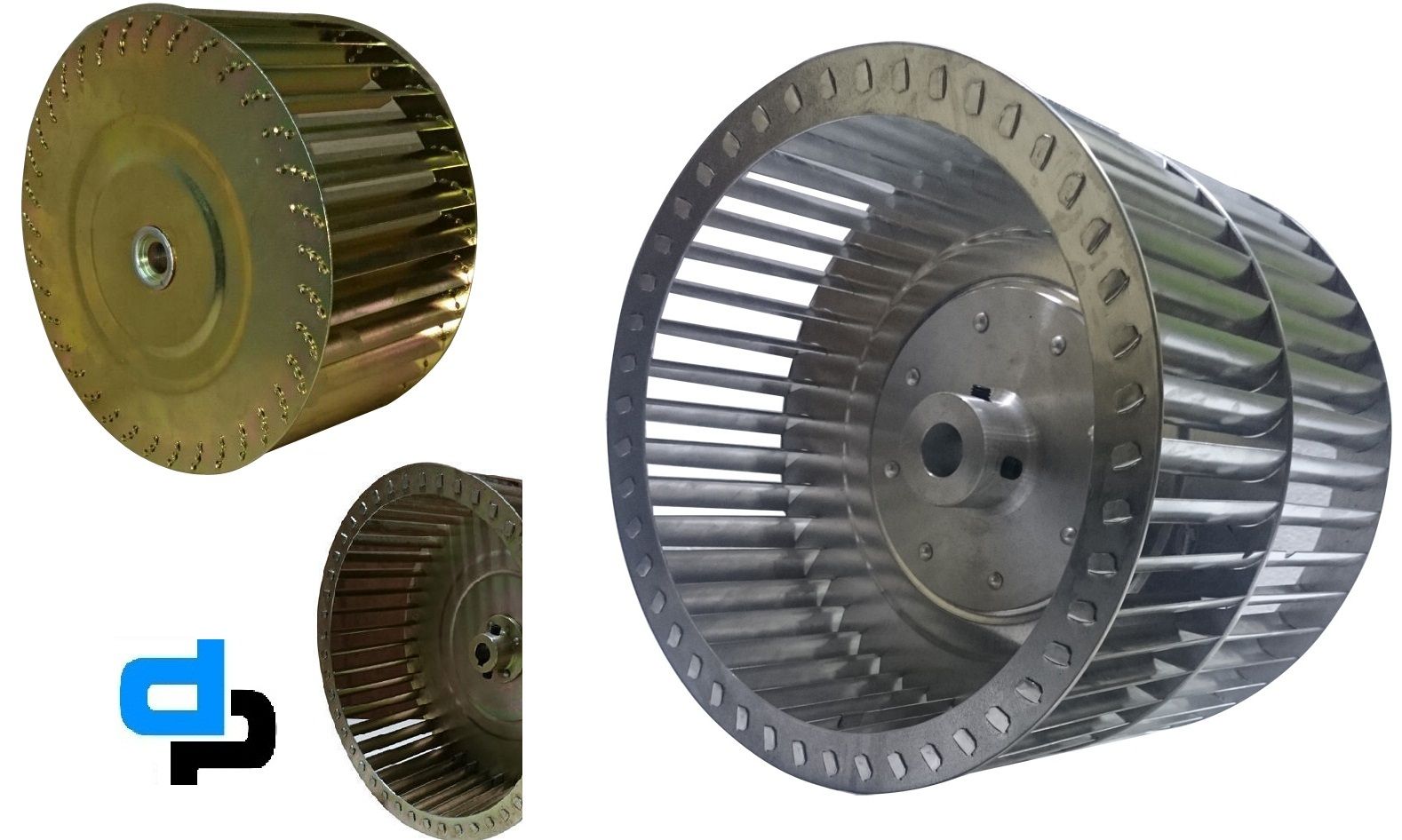

DIDW Centrifugal Fan 160 MM X 200 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 14 | DP 65 80 | 160 X 200 X 135 | 6.5 X 8 | 12.70 (1/2) & 15 MM | AL. / GI. |

Robust Construction for Industrial Applications

Engineered with a dynamically balanced mild steel impeller and powder-coated finish, this centrifugal fan guarantees longevity and performance in demanding environments. Equipped with double sealed ball bearings, it supports reliable operation for up to 10 years.

Optimized Performance and Low Noise

The backward curved impeller and precision motor operate at 2800 RPM, ensuring efficient airflow (up to 1500 m3/h) while maintaining noise levels under 70 dB. This makes it ideal for settings where quiet operation is essential, including HVAC and industrial exhaust systems.

Versatile Installation and Operation

Designed for base/foot mounting, the fan accommodates direct or belt drive setups and supports both rotation directions. With its IP44/IP55 enclosure and Class F/H insulation, it withstands varied environments, making it suitable for diverse industrial and commercial uses.

FAQs of DIDW Centrifugal Fan 160 MM X 200 MM:

Q: How is the DIDW Centrifugal Fan installed?

A: This fan is base/foot mounted, allowing easy placement on flat surfaces. Its flexible design supports both direct and belt drive systems, making installation simple in HVAC and industrial ventilation setups.Q: What applications is this centrifugal fan suitable for?

A: It is ideal for air ventilation, HVAC systems, and industrial exhaust, owing to its high flow rate, durable construction, and efficient noise control. Its versatility supports diverse environments such as factories, commercial buildings, and warehouses.Q: When should the fans rotation direction be selected?

A: The rotation directionclockwise or counter-clockwiseis chosen based on the specific airflow requirements and duct layout during installation, ensuring optimal system performance and compatibility.Q: Where can the DIDW Centrifugal Fan be used for maximum benefit?

A: It delivers maximum benefits in spaces needing robust air movement, such as air handling units, exhaust systems, and ventilation for manufacturing facilities, thanks to its high capacity and adaptable design.Q: What process is followed for maintaining the fan?

A: Regular maintenance involves inspecting the double sealed ball bearings, checking electrical connections, and cleaning the powder-coated surfaces. Such routine care prolongs operational life up to 10 years.Q: How does the fans backward curved impeller improve usage?

A: The backward curved impeller design enhances airflow efficiency, reduces energy consumption, and minimizes noise, making it more suitable for environments where performance and quiet operation are priorities.Q: What are the benefits of the powder-coated finish and Class F/H insulation?

A: Powder coating provides corrosion resistance, while Class F/H insulation ensures reliable operation under varying temperatures, offering durability and safe performance for extended periods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 230 MM X 228 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Voltage : 230 V

Frequency (MHz) : 50 Hz

Product Type : Others, Double Inlet Double Width Centrifugal Fan

DIDW Centrifugal Fan 230 MM X 203 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Voltage : 230 V

Frequency (MHz) : 50 Hz

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

DIDW Centrifugal Fan 180 MM X 178 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Voltage : 230 V AC

Frequency (MHz) : 50 Hz

Product Type : Others, Centrifugal Fan

DIDW Centrifugal Fan 230 MM X 254 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Voltage : 230 V AC

Frequency (MHz) : 50 Hz

Product Type : Others, DIDW (Double Inlet Double Width) Centrifugal Fan

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS