DIDW Centrifugal Fan 380 MM X 380 MM

DIDW Centrifugal Fan 380 MM X 380 MM Specification

- Output Power

- 1.1 kW

- Motor Power

- 1.1 kW

- Power

- 1.1 kW

- Max Pressure

- 550 Pa

- Pressure Range

- 300-550 Pa

- Life Span

- 8-10 Years

- Flow Rate

- 1500 m/hr

- Product Type

- Double Inlet Double Width Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1500 CMH

- Pressure

- 550 Pascal

- Application

- Ventilation, HVAC, Air Handling Units, Industrial & Commercial Air Movement

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- <80 dB

- Power Source

- Electric

- Voltage

- 380 V

- Weight

- 34 kg

- Dimension (L*W*H)

- 380 mm x 380 mm

- Color

- Blue

DIDW Centrifugal Fan 380 MM X 380 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Tripura, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Central India, Chhattisgarh, All India

About DIDW Centrifugal Fan 380 MM X 380 MM

DIDW Centrifugal Fan 380 MM X 380 MM

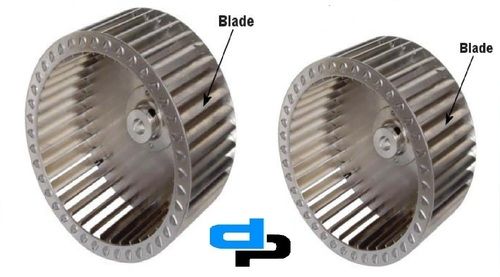

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 57 | DP 15 15 | 380 X 380 X 300 | 15 X 15 | 25 MM,30 MM,& 1.25 | AL. / GI. |

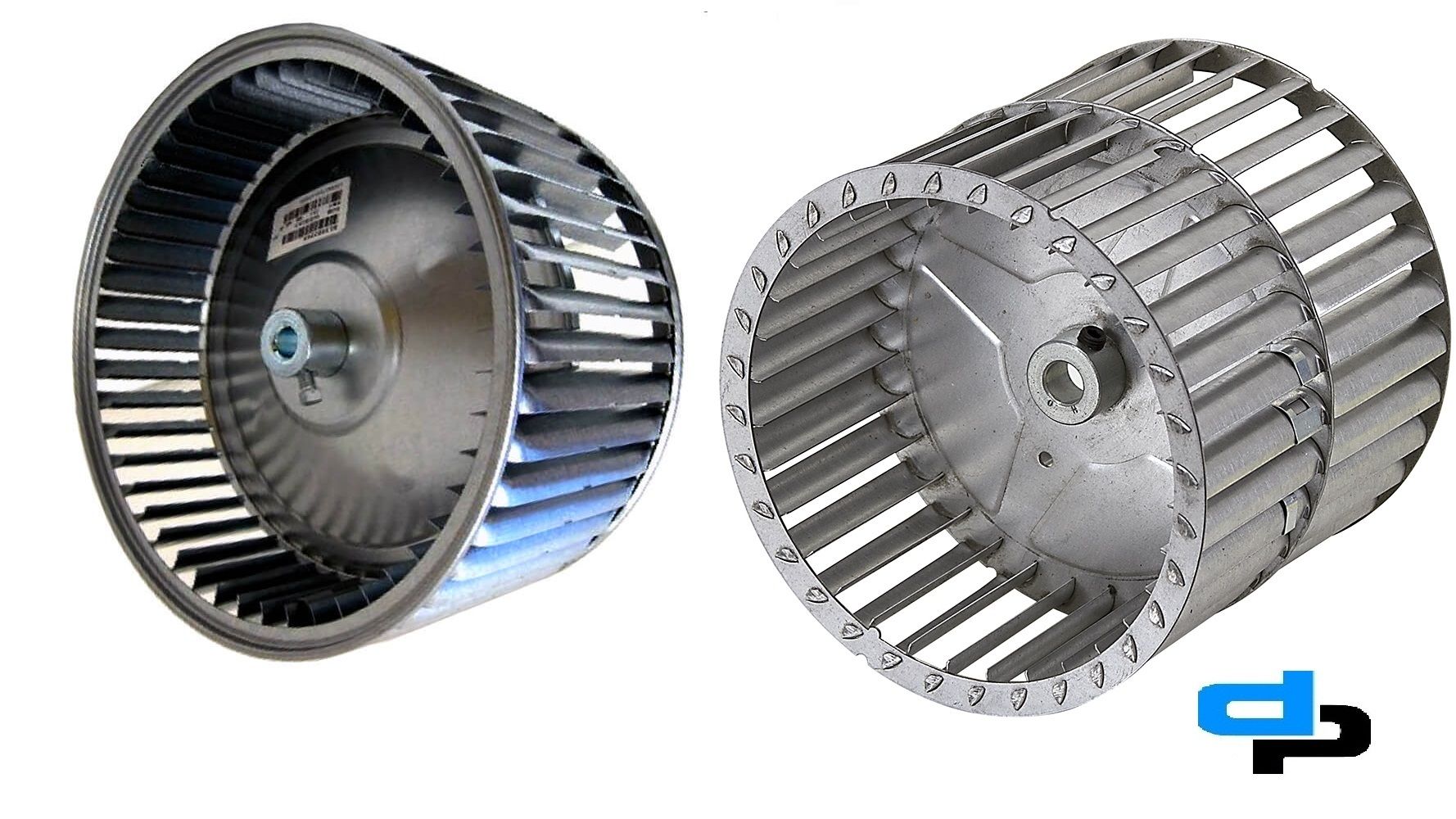

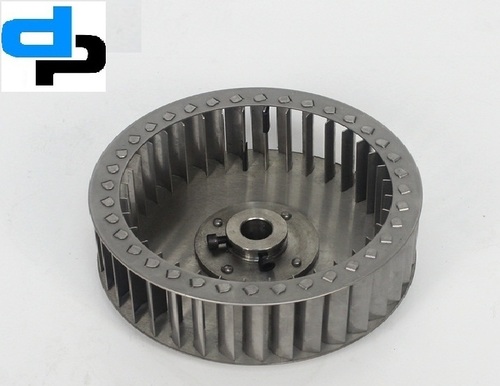

Optimized Air Movement for Versatile Applications

This centrifugal fan is tailored for use in commercial and industrial ventilation, HVAC systems, and air handling units. Its 12-blade, forward curved impeller design ensures excellent air distribution, making it suitable for spaces requiring efficient airflow management. The robust construction and powder-coated finish guarantee long-lasting service in demanding environments.

Built for Reliability and Efficiency

Equipped with a direct drive IP55 motor and flanged inlet and outlet connections, the fan ensures secure installation and consistent performance. Operating within a wide temperature range, it maintains reliable airflow at low noise levels, contributing to a comfortable and safe environment. Its galvanized steel blades and heavy-duty frame withstand industrial rigors and maintain optimal efficiency.

FAQs of DIDW Centrifugal Fan 380 MM X 380 MM:

Q: How is the DIDW Centrifugal Fan installed for optimal performance?

A: The fan is base-mounted and features flanged inlet and outlet connections for secure installation. It should be positioned to ensure horizontal discharge, in well-ventilated locations suitable for its 380 mm x 380 mm dimensions and airflow needs.Q: What are the main benefits of using a forward curved impeller in this fan?

A: Forward curved impellers enhance airflow efficiency, reduce vibration, and maintain lower noise levels (<80 dB), making them ideal for HVAC and air handling unit applications where quiet and effective air movement is required.Q: Where can this centrifugal fan be ideally utilized?

A: This fan is well-suited for commercial buildings, industrial settings, and HVAC systems, including ventilation and air handling units. It excels wherever reliable and consistent air movement is crucial, such as factories, warehouses, and workshops.Q: What process ensures the longevity and protection of the fan components?

A: The fans heavy-duty welded frame is treated with a powder-coated finish for corrosion resistance, while the IP55 motor protection safeguards against dust and water ingress. These features collectively extend its operational life to 810 years.Q: When should the centrifugal fan be serviced or maintained?

A: Routine maintenance, such as cleaning and checking for wear, is recommended every six months to ensure optimal performance and longevity. Ensure the motor and blades remain free of debris to maintain efficiency.Q: How does the fan manage extreme temperature conditions?

A: The DIDW Centrifugal Fan operates efficiently within a temperature range of -20C to 60C, making it suitable for environments with fluctuating thermal conditions, without compromising airflow or motor reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

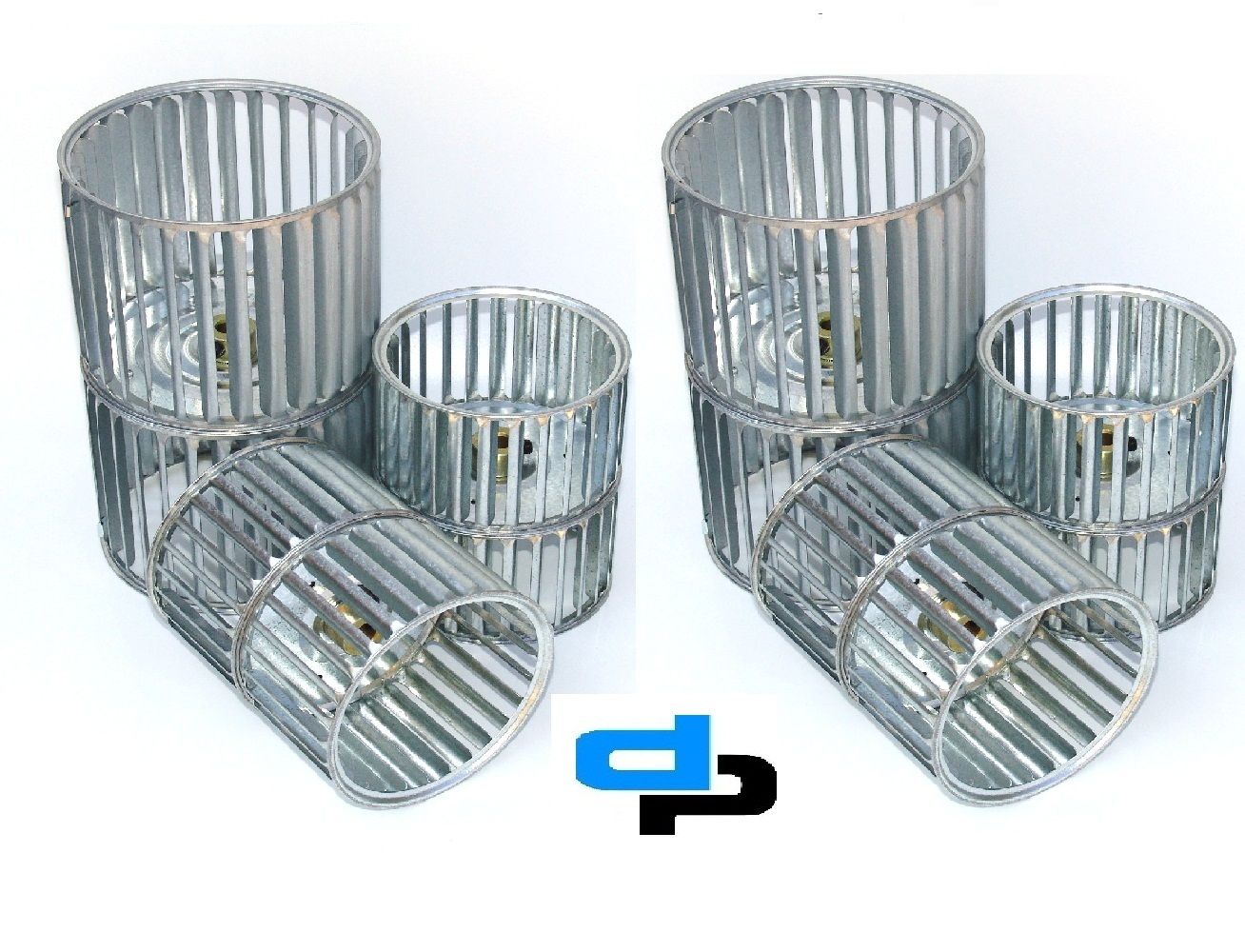

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 200 MM X 127 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Power : 0.25 HP

Motor Speed : 2800 RPM

Capacity : 250300 m/h

DIDW Centrifugal Fan 250 MM X 280 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, DIDW Centrifugal Fan

Power : 1.5 kW

Motor Speed : 2800 RPM

Capacity : 1200 CFM

DIDW Centrifugal Fan 160 MM X 228 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Power : 0.37 kW

Motor Speed : 2800 RPM

Capacity : 600 m/hr

DIDW Centrifugal Fan 151 MM X 203 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, DIDW Centrifugal Fan

Power : 1 HP

Motor Speed : 2880 RPM

Capacity : 700 CFM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS