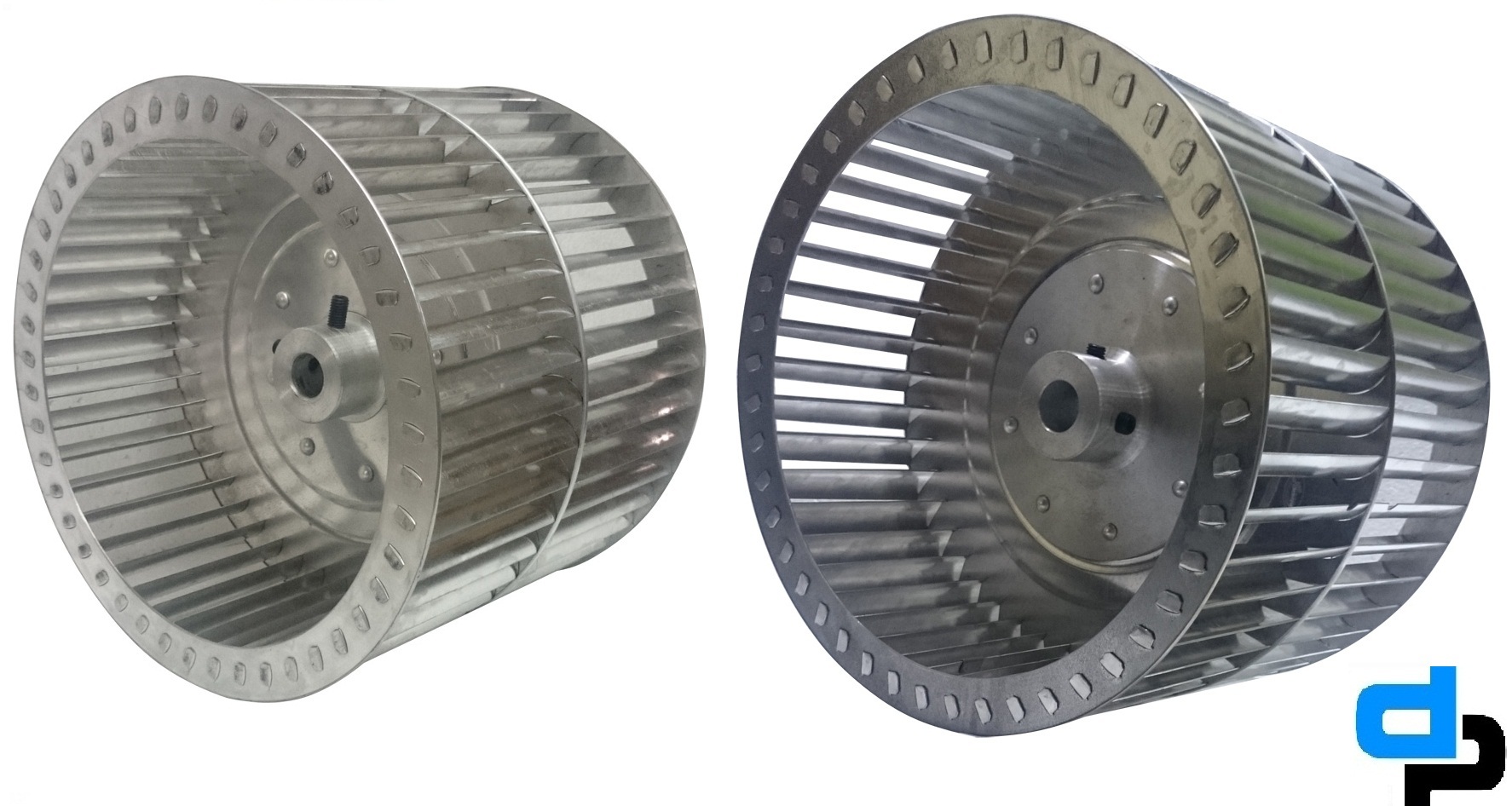

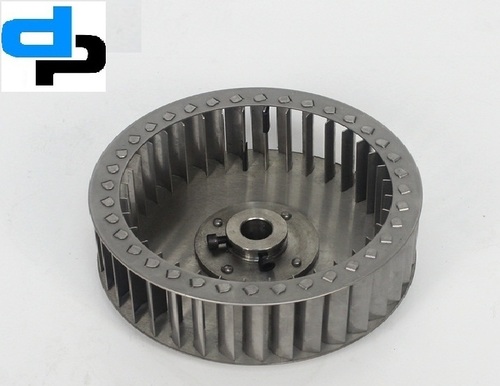

DIDW Centrifugal Fan 151 MM X 203 MM

DIDW Centrifugal Fan 151 MM X 203 MM Specification

- Max Pressure

- 300 mmWG

- Power

- 1 HP

- Pressure Range

- 150-300 mmWG

- Motor Power

- 0.75 kW

- Output Power

- 0.75 kW

- Life Span

- 10 Years

- Flow Rate

- 1190 m/hr

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 700 CFM

- Pressure

- 300 mmWG

- Application

- Industrial ventilation, HVAC systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2880 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 230 V

- Weight

- 15 kg

- Dimension (L*W*H)

- 151 mm x 203 mm

- Color

- Blue

DIDW Centrifugal Fan 151 MM X 203 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Asia, Middle East

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Nagaland, Uttarakhand, Daman and Diu, South India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Lakshadweep, Uttar Pradesh, Haryana, Gujarat, Delhi, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 151 MM X 203 MM

DIDW Centrifugal Fan 151 MM X 203 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 10 | DP 6 80 | 151 X 203 X 122 | 6 X 8 | 12.70 (1/2) & 15 MM | AL. / GI. |

Robust Industrial Ventilation Solution

Specially designed for industrial spaces and HVAC applications, the DIDW Centrifugal Fan offers powerful air movement and pressure control within compact dimensions. Its backward-curved impeller provides stable airflow, making it ideal for maintaining air quality and temperature. The powder-coated mild steel structure enhances longevity, while base mounting ensures secure installation in diverse setups.

Precision Engineering for Longevity

Equipped with sealed ball bearings and Class F insulation, this fan ensures reliable operation and safety even at high speeds of 2880 RPM. The TEFC enclosure protects internal components from dust and moisture, maximizing operational life up to 10 years. Quality manufacturing standards deliver peace of mind through the manufacturers warranty, positioning it as a trusted choice for industrial use.

FAQs of DIDW Centrifugal Fan 151 MM X 203 MM:

Q: How is the DIDW Centrifugal Fan installed in an industrial setting?

A: This fan is base mounted, allowing secure placement on flat surfaces within industrial spaces. Installation generally involves securing the unit using bolts and connecting to a 230 V single-phase power source as specified.Q: What are the key benefits of the backward curved impeller design?

A: The backward curved impeller offers higher efficiency, reduced noise, and minimized risk of overloading. This design facilitates stable airflow and effective pressure management, making it suitable for demanding ventilation requirements.Q: When should the DIDW Centrifugal Fan be used?

A: This fan is ideal for industrial ventilation and HVAC systems, particularly where robust air movement and noise control below 80 dB are needed. It supports continuous operation in environments of up to 60C.Q: Where can this fan be applied within a facility?

A: The fan is versatile for mounting in air handling units, exhaust systems, or ductwork within factories, warehouses, and commercial HVAC installations, thanks to its compact size and efficient output.Q: What is the process for maintaining the fan and ensuring longevity?

A: Routine checks of sealed ball bearings, cleaning of the powder-coated surfaces, and inspection of electrical connections are recommended. The TEFC enclosure and durable build reduce maintenance frequency, supporting a long service life.Q: How does the insulation Class F contribute to safety and performance?

A: Class F insulation allows the motor windings to withstand higher temperatures, enhancing safety and reliability during prolonged operation under demanding industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 280 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Life Span : 810 Years

Flow Rate : 1200 CFM

Material : other , Mild Steel

Color : Grey

DIDW Centrifugal Fan 200 MM X 127 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Life Span : 10,000 Operating Hours

Flow Rate : 250300 m/h

Material : other , Mild Steel (MS), Powder Coated

Color : Silver / Metallic Grey

DIDW Centrifugal Fan 250 MM X 254 MM

Price 3000 INR

Minimum Order Quantity : 5 Pieces

Life Span : Around 7 Years

Flow Rate : 1500 m/hr

Material : other , Mild Steel

Color : Blue

DIDW Centrifugal Fan 230 MM X 254 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Life Span : 57 Years

Flow Rate : 600 CFM

Material : other , Galvanized Steel

Color : Silver/Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free