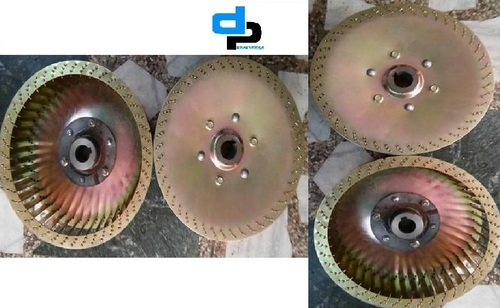

DIDW Centrifugal Fan 200 MM X 127 MM

MOQ : 5 Pieces

DIDW Centrifugal Fan 200 MM X 127 MM Specification

- Flow Rate

- 250-300 m/h

- Power

- 0.25 HP

- Pressure Range

- 10 to 50 mmWG

- Max Pressure

- 50 mmWG

- Life Span

- 10,000 Operating Hours

- Output Power

- 185 W

- Motor Power

- 185 W

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel (MS), Powder Coated

- Capacity

- 250-300 m/h

- Pressure

- Up to 50 mmWG

- Application

- Air Ventilation, HVAC, Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 75 dB(A)

- Power Source

- Electric

- Voltage

- 220-240 V AC

- Weight

- Approx. 3.5 kg

- Dimension (L*W*H)

- 200mm x 127mm

- Color

- Silver / Metallic Grey

DIDW Centrifugal Fan 200 MM X 127 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Meghalaya, All India, South India, North India, East India, Andhra Pradesh, Assam, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Arunachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Central India, West India

About DIDW Centrifugal Fan 200 MM X 127 MM

DIDW Centrifugal Fan 200 MM X 127 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 23 | DP 8 50 | 200 X 127 X 158 | 8 X 5 | 12.70 (1/2) & 15 MM | AL. / GI. |

Reliable Performance and Energy Efficiency

Operating at a motor speed of 2800 RPM with a power requirement of just 0.25 HP (185 W), the DIDW Centrifugal Fan achieves strong output while conserving energy. Its direct drive system minimizes maintenance needs and maximizes the stability of air delivery. The fan is base or foot mounted, allowing flexible installation across various commercial and industrial environments.

Durable Construction and Extended Life Span

Manufactured from quality mild steel and finished with powder coating, the fan is engineered for longevity in demanding environments. With precision ball bearings and a totally enclosed fan cooled (TEFC) motor, it endures continuous duty cycles and temperature ranges from -10C to +60C, delivering up to 10,000 hours of reliable operation.

Versatile Applications and Easy Installation

Designed for air ventilation, HVAC, and exhaust uses, this centrifugal fan is an excellent choice for offices, factories, laboratories, and more. Its riveted or welded construction ensures stability, while the base-mounted design allows for straightforward integration into new or existing systems.

FAQs of DIDW Centrifugal Fan 200 MM X 127 MM:

Q: How is the DIDW Centrifugal Fan installed and what mounting options are available?

A: The fan is designed for base or foot mounting, making installation easy and adaptable to various spaces. Its compact dimensions (200mm x 127mm) ensure it fits seamlessly into ventilation, HVAC, or exhaust systems.Q: What are the primary applications of this centrifugal fan?

A: This fan is widely used for air ventilation, HVAC, and exhaust functions in commercial, industrial, and institutional environments. Its design supports efficient airflow in offices, workshops, and factory settings.Q: What type of maintenance does the centrifugal fan require for optimal performance?

A: Thanks to its direct drive and ball bearing system, the fan requires minimal maintenance. Regularly inspecting the enclosure and cleaning dust accumulation on the blades will support continuous, reliable operation.Q: Where can this centrifugal fan be sourced from, and who are the primary customers?

A: The product is supplied by authorized exporters, manufacturers, suppliers, and traders throughout India, serving commercial, industrial, and HVAC contractors who demand reliability and performance.Q: What features contribute to the durability and long lifespan of the fan?

A: Durability is ensured by its mild steel, powder-coated construction, TEFC motor enclosure, and high-quality ball bearings. These features enable it to deliver up to 10,000 operating hours, even in demanding environments.Q: How does the fan perform under varying pressures and flow rates?

A: The fan efficiently operates within a pressure range of 10 to 50 mmWG, reaching flow rates of 250-300 m/h. It is engineered to maintain consistent performance across diverse application conditions.Q: What benefits does the forward-curved impeller and double-width blade design offer?

A: This configuration enhances airflow and pressure stability, reduces noise output below 75 dB(A), and ensures overall efficiency, making it ideal for environments where quiet operation and dependable performance are critical.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 330 MM X 250 MM

Price 7500 INR

Minimum Order Quantity : 5 Pieces

Color : Blue / Grey

Life Span : Long Lasting

Motor Power : 1.5 kW

Output Power : 1.5 kW

DIDW Centrifugal Fan 151 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Color : Silver

Life Span : 57 Years

Motor Power : 0.5 HP

Output Power : 0.37 kW

DIDW Centrifugal Fan 151 MM X 203 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Color : Blue

Life Span : 10 Years

Motor Power : 0.75 kW

Output Power : 0.75 kW

DIDW Centrifugal Fan 530 MM X 380 MM

Price 18500 INR

Minimum Order Quantity : 2 Pieces

Color : Blue

Life Span : Approx. 810 Years

Motor Power : 2.2 kW

Output Power : 2.2 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS