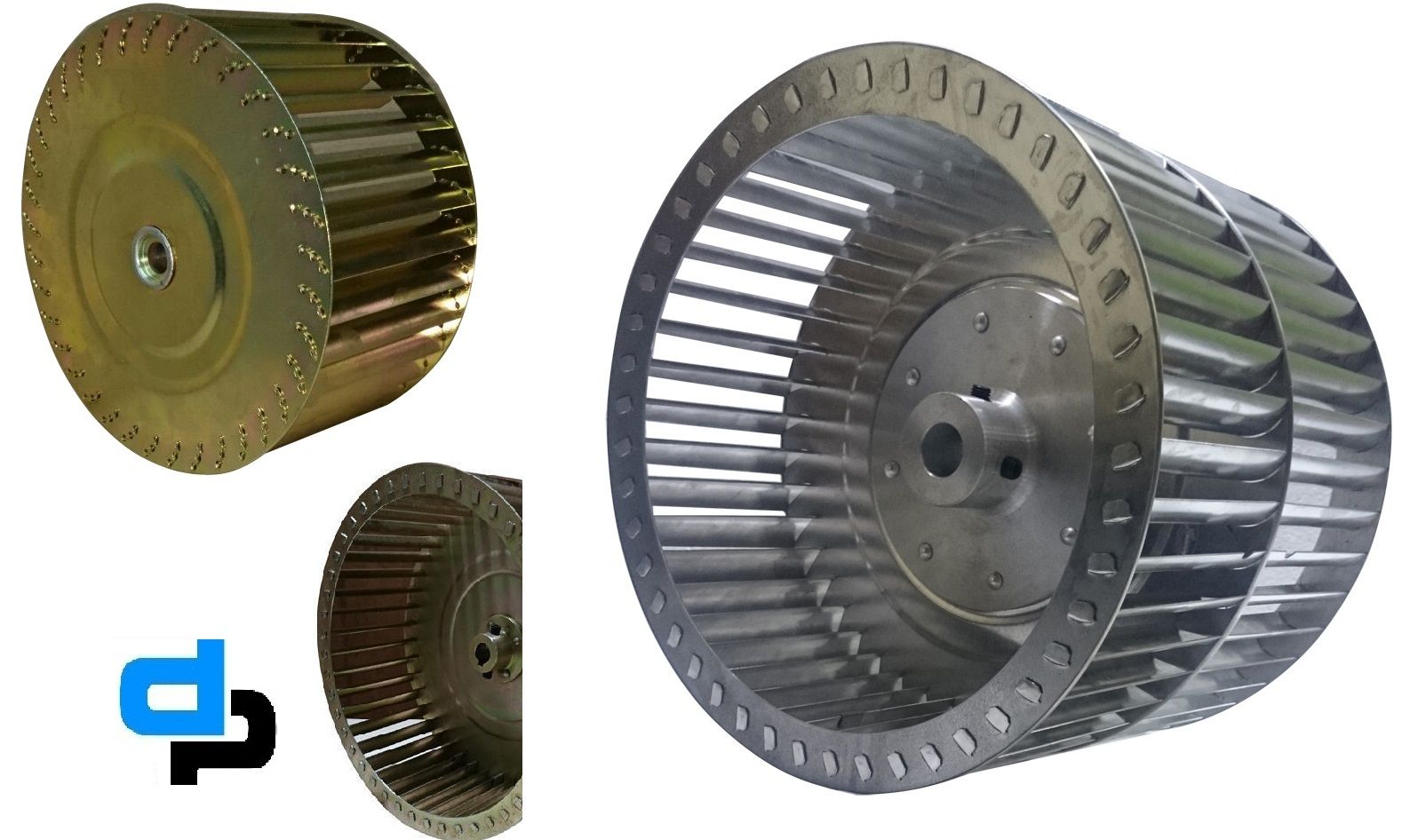

DIDW Centrifugal Fan 151 MM X 165 MM

DIDW Centrifugal Fan 151 MM X 165 MM Specification

- Power

- 0.18 kW

- Max Pressure

- 180 Pa

- Life Span

- 10 Years (typical)

- Pressure Range

- 150-180 Pa

- Output Power

- 0.18 kW

- Flow Rate

- 520 m/h

- Motor Power

- 0.18 kW

- Product Type

- Double Inlet Double Width Centrifugal Fan

- Material

- Mild Steel / Galvanized

- Capacity

- 520 m/h

- Pressure

- 175 Pa

- Application

- HVAC Systems, Industrial Air Handling, Ventilation

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <65 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- 5.6 kg

- Dimension (L*W*H)

- 151 mm x 165 mm x 210 mm (approx.)

- Color

- Blue / Silver

DIDW Centrifugal Fan 151 MM X 165 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Haryana, Nagaland, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 151 MM X 165 MM

DIDW Centrifugal Fan 151 MM X 165 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 8 | DP 6 65 | 151 X 165 X 122 | 6 X 6.5 | 12.70 (1/2) & 15 MM | AL. / GI. |

High Performance & Compact Design

This centrifugal fan combines high airflow rates (520 m/h) with a relatively compact size (151 mm x 165 mm x 210 mm), making it well-suited for installations where space efficiency and robust air movement are critical. Its forward curved air discharge and direct drive setup optimize energy use and minimize vibration.

Engineered for Durability & Ease of Maintenance

Constructed with dynamically balanced mild steel impellers and available in powder coated or galvanized finishes, the fan ensures longevity even under intensive use. The easy-removable impeller design streamlines routine maintenance, enabling quick cleaning or replacement to minimize downtime.

Versatile Application Across Environments

Perfectly suited for HVAC systems, industrial air handling, and ventilation projects, this fans IP44-rated motor and Class B/F insulation provide enhanced safety and operational flexibility. It operates efficiently across a temperature range of -10C to 60C and humidity levels up to 95%.

FAQs of DIDW Centrifugal Fan 151 MM X 165 MM:

Q: How is the DIDW Centrifugal Fan typically installed?

A: This fan can be mounted using either a base or flange mount, allowing flexibility in different installation environments, such as ducted systems in HVAC applications or direct placement in industrial air handling setups.Q: What maintenance procedures does the DIDW Centrifugal Fan require?

A: The fan is designed with an easy-removable impeller, making routine maintenance simpler. Periodic inspection and cleaning of the impeller and casing, as well as checking the sealed ball bearings, help maintain its performance and prolong lifespan.Q: Where can I use this centrifugal fan most effectively?

A: Ideal applications include HVAC systems, industrial ventilation, and general air handling in commercial or manufacturing facilities. Its durable construction and IP44 protection ensure suitability for both indoor environments with moderate humidity and temperature variations.Q: What benefits does the dynamically balanced mild steel impeller offer?

A: A dynamically balanced impeller ensures smoother operation, reduced vibration, decreased noise levels, and extended bearing life. This results in more reliable airflow and less frequent maintenance or repairs.Q: When should I consider replacing the fan?

A: With a typical lifespan of 10 years, replacement may be needed if you notice a significant drop in airflow, excessive vibration, or persistent noise that cannot be resolved by maintenance. Always follow the manufacturers guidelines for inspection intervals.Q: What is the process for connecting the fan to an electrical supply?

A: The fan operates on a 220-240 V electric supply at 50 Hz. Ensure all connections are made according to local electrical standards, and verify that the power source matches the fans motor specifications for safe and efficient operation.Q: What are the key benefits of using this centrifugal fan in my ventilation system?

A: The main advantages include high airflow capacity, efficient direct drive design, low noise, robust construction resistant to wear, and straightforward servicing. These features collectively lower long-term operating costs and improve system reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 330 MM X 330 MM

Price 8500 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Pressure : Other, Up to 150 mm WG

Flow Rate : 1200 CFM

DIDW Centrifugal Fan 160 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Pressure : Other, 280 Pa

Flow Rate : 350 m/h

DIDW Centrifugal Fan 180 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Pressure : Other, 280 Pa

Flow Rate : 540 m/h

DIDW Centrifugal Fan 300 MM X 305 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Frequency (MHz) : 50 Hz

Pressure : Other, 150 mm WG

Flow Rate : 850 m/h

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS