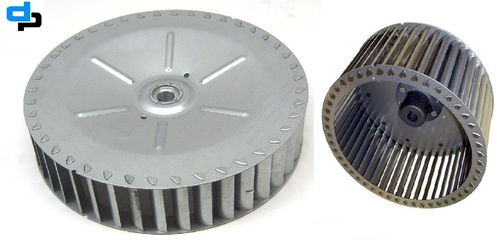

DIDW Centrifugal Fan 160 MM X 152 MM

DIDW Centrifugal Fan 160 MM X 152 MM Specification

- Life Span

- 5 Years

- Motor Power

- 0.25 HP

- Flow Rate

- 350 m/h

- Output Power

- 180 W

- Power

- 180 W

- Max Pressure

- 280 Pa

- Pressure Range

- 150 - 280 Pa

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 350 m/h

- Pressure

- 280 Pa

- Application

- HVAC, Ventilation, Industrial Cooling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2880 RPM

- Noise Level

- Less than 70 dB

- Power Source

- Electric

- Voltage

- 230 V

- Weight

- 5.5 kg

- Dimension (L*W*H)

- 160 mm x 152 mm

- Color

- Gray

DIDW Centrifugal Fan 160 MM X 152 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Gujarat, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About DIDW Centrifugal Fan 160 MM X 152 MM

DIDW Centrifugal Fan 160 MM X 152 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 12 | DP 65 60 | 160 X 152 X 135 | 6.5 X 6 | 12.70 (1/2) & 15 MM | AL. / GI. |

Reliable Air Management for Various Applications

Engineered for versatility, the DIDW Centrifugal Fan provides optimal airflow for HVAC, ventilation, and industrial cooling environments. Its forward and backward air flow direction enhances compatibility across systems, ensuring stable performance whether installed in commercial or manufacturing settings.

Durability Meets Efficiency

Constructed from mild steel and galvanized steel blades, this fan combines resilience with energy efficiency. The totally enclosed design and Class F insulation safeguard internal components against dust and moisture, while the efficient 180 W motor guarantees prolonged, maintenance-free operation.

FAQs of DIDW Centrifugal Fan 160 MM X 152 MM:

Q: How do I install the DIDW Centrifugal Fan with base mounting?

A: The DIDW Centrifugal Fan is designed for easy base mounting. Secure the base-mounted frame on a flat surface using suitable fasteners. Ensure proper alignment with ductwork and electrical systems, following all local safety guidelines and manufacturer instructions.Q: What are the benefits of using a backward curved impeller in this fan?

A: A backward curved impeller improves energy efficiency and reduces noise production. This design is particularly effective for handling higher static pressures, ensuring stable air delivery and minimizing risks of dust accumulation on the blades.Q: When should I consider using this centrifugal fan in my systems?

A: This fan is ideal when your project requires consistent airflow up to 350 m/h and a static pressure of up to 280 Pa, particularly in HVAC, ventilation, and industrial cooling applications that demand quiet and efficient operation.Q: Where can this centrifugal fan be utilized?

A: The design supports use in commercial buildings, factories, warehouses, and industrial settings across India and other regions. Its suitable for areas needing reliable air circulation and temperature control, such as machinery rooms or ducted air systems.Q: What process should be followed for regular maintenance?

A: Routine checks should include cleaning the impeller blades, ensuring the enclosure is free from dust accumulation, and verifying that electrical connections remain secure. With proper care, the fans lifespan can reach up to 5 years.Q: How does the totally enclosed enclosure benefit the fans operation?

A: The totally enclosed enclosure protects the fans motor and internal components from dust, debris, and moisture. This extends service life, reduces maintenance intervals, and ensures safer operation in demanding environments.Q: What makes this centrifugal fan suitable for industrial usage?

A: Its construction with mild and galvanized steel, high pressure handling capacity, low noise output, and robust insulation make it ideal for challenging industrial environments where reliability and durability are paramount.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 180 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Voltage : 230 V AC

Frequency (MHz) : 50 Hz

Material : other , Mild Steel

Max Pressure : 300 Pa

DIDW Centrifugal Fan 230 MM X 178 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Voltage : 220240 V

Frequency (MHz) : 50 Hz

Material : other , Galvanized Steel

Max Pressure : 350 Pa

DIDW Centrifugal Fan 530 MM X 455 MM

Price 21000.00 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Frequency (MHz) : 50 Hz

Material : other , Mild Steel

Max Pressure : 410 Pa

DIDW Centrifugal Fan 272 MM X 272 MM

Price 3500 INR

Minimum Order Quantity : 5 Pieces

Voltage : 220240 V

Frequency (MHz) : 50 Hz

Material : other , Galvanized Steel

Max Pressure : 350 Pa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS