Channel Type Pre Filters

Channel Type Pre Filters Specification

- Flow Rate

- 1000-6000 m/h

- Efficiency (%)

- Up to 85%

- Filtration Grade

- Pre-filter

- Media Type

- Non-woven / metal mesh

- Cleaning Method

- Washable / Vacuum Cleanable

- Connecting Type

- Flanged / Channel Fitted

- Pressure

- 0.5-2 bar

- Temperature Range

- Up to 80C

- Capacity

- Custom capacity per model

- Filter Type

- Channel Type Pre Filter

- Condition

- New

- Material

- Stainless Steel / Aluminum

- Mesh

- Fine mesh / Customizable

- Diameter

- Standard: 100mm to 500mm

- Construction

- Channel type welded frame

- Medium Filter

- Synthetic Fiber / Metal Mesh

- Weight

- 2.5 kg (Varies by size)

- Shape

- Rectangular / Square

- Feature

- Superior oil, dust, and dirt filtration

- Installation Type

- Front/Rear access

- Environmental Compliance

- RoHS compliant

- Usage

- HVAC, Air Handling Units, Dust Collection Systems

- Inlet/Outlet Type

- Customizable

- Service Life

- Up to 2 years

- Size Range

- From 300mm x 300mm to 1200mm x 1200mm

- Edge Protection

- PVC gasket sealing

- Color

- Metallic/Silver

- Replacement Interval

- 3-6 months (recommended)

- Maximum Humidity

- Up to 85% RH

- Frame Thickness

- 0.5 mm to 1.00 mm

- Surface Finish

- Smooth/Polished

Channel Type Pre Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Main Export Market(s)

- Eastern Europe, Western Europe, Africa, Central America, Australia, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Channel Type Pre Filters

Key features:

- Quality assured

- Longer service life

- Seamless quality

Note: As per the needs of the clients, we manufacture them in allotted time frame at reasonable prices in a variety of demanded sizes and specifications.

Reliable Oil, Dust, & Dirt Filtration

Channel Type Pre Filters offer efficient pre-filtration for air handling units, HVAC, and dust collection systems, removing contaminants before they reach sensitive equipment. With synthetic fiber or metal mesh media, these filters achieve up to 85% efficiency and are suitable for demanding environments where superior filtration and extended service life are essential.

Flexible Design & Superior Build Quality

These pre filters come in several standard and custom dimensions, from a compact 300mm x 300mm up to a large 1200mm x 1200mm, and in round diameters ranging from 100mm to 500mm. The channel welded frames, flanged or channel fitting options, and front/rear access capability support various installation requirements in industrial and commercial settings.

Smart Maintenance & Environmental Compliance

RoHS compliance ensures environmental safety. The washable and vacuum-cleanable media, coupled with a recommended replacement interval every 3-6 months and a service life of up to 2 years, minimize operational costs and contribute to sustainability efforts.

FAQs of Channel Type Pre Filters:

Q: What applications are Channel Type Pre Filters suitable for?

A: Channel Type Pre Filters are ideally used in HVAC systems, air handling units, and dust collection systems. Their design and efficiency make them suitable for removing coarse contaminants in industrial, commercial, and environmental compliance settings.Q: How do I install these pre filters in my system?

A: These filters are designed for both front and rear access installation, making them adaptable to different system layouts. They can be fitted using flanged or channel connections, depending on your configuration. Detailed instructions are provided with each unit for simple integration.Q: When should I replace or clean my Channel Type Pre Filter?

A: Regular cleaning is recommended every 3-6 months, depending on operational environment and dust load. With proper maintenance, these filters can have a service life of up to 2 years. Maintenance can be performed either by washing or vacuum cleaning the filter media.Q: What benefits do these filters provide over standard pre filters?

A: These filters offer up to 85% filtration efficiency for oil, dust, and dirt, and are built with durable stainless steel or aluminum frames. Their design supports high flow rates (1000-6000 m/h), customizable sizes, and easy maintenance, providing reliable and long-lasting filtration performance.Q: Where are these Channel Type Pre Filters manufactured and supplied?

A: This product is made by exporters, manufacturers, suppliers, and traders in India, and is available for distribution both locally and internationally.Q: What is the process for cleaning and maintaining these filters?

A: To clean the filter, remove it from its housing and wash or vacuum the media thoroughly to remove trapped particulates. After drying, the filter can be reinstalled. Regular maintenance helps maintain filter efficiency and extends its operational life.Q: Can the inlet and outlet configuration or size be customized?

A: Yes, both inlet and outlet types are customizable to meet specific requirements. Filters can be tailored to suit various system designs, ensuring compatibility with your equipment and optimal air flow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filters-Manufacturers,Suppliers & Exporters in Category

Paper Paint Booth Filter

Medium Filter : Paper

Condition : New

Construction : Other, Pleated Cardboard or Paper, Rigid structure

Filtration Grade : Other, Primary

Connecting Type : Other, Slot or Frame

Pressure : Initial Pressure Drop: 30 Pa

Catridge Filter for Dust Collector

Medium Filter : Dust, Other

Condition : New

Construction : Other, Rigid & durable

Filtration Grade : Other, Medium to fine filtration

Connecting Type : Openend with flange, Other

Pressure : Operates under standard pressure range

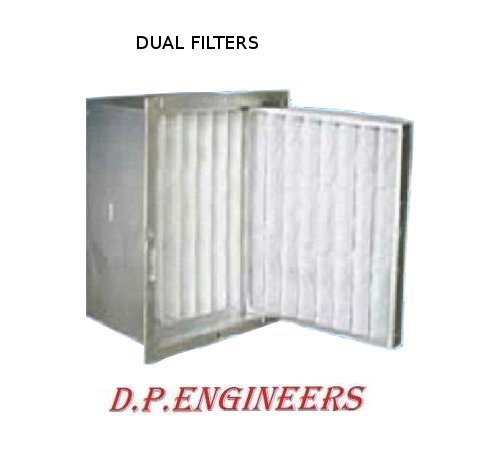

Dual Filters

Medium Filter : Other, Stainless Steel Mesh

Condition : New

Construction : Other, Robust welded construction with corrosionresistant coating

Filtration Grade : Other, Medium Filtration

Connecting Type : Flanged

Pressure : Up to 10 bar

Fine Filters

Medium Filter : Other, Liquid and Air

Condition : New

Construction : Other, Rugged welded design

Filtration Grade : Other, Fine

Connecting Type : Other, Flanged / Threaded

Pressure : Up to 5 bar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS