Fine Filters

Fine Filters Specification

- Temperature Range

- -10C to 110C

- Filtration Grade

- Fine

- Pressure

- Up to 5 bar

- Capacity

- Up to 5000 LPH

- Efficiency (%)

- 99

- Connecting Type

- Flanged / Threaded

- Media Type

- Synthetic / Stainless Steel Mesh

- Cleaning Method

- Manual / Backwash

- Flow Rate

- 200-1000 m3/hr (customizable)

- Filter Type

- Cartridge / Pleated Type

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Fine (customizable up to 325 mesh)

- Diameter

- As per requirement (commonly 50 mm to 500 mm)

- Construction

- Rugged welded design

- Medium Filter

- Liquid and Air

- Weight

- varies as per size

- Shape

- Cylinder

- Feature

- High dust holding capacity, Easy installation, Replaceable filter element, High efficiency filtration

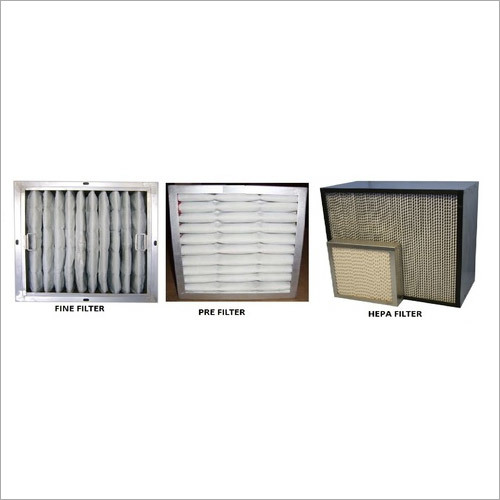

About Fine Filters

Fine Filters

We are engaged in offering a wide range of filters. Among these we offer Fine Filters. These have been specially designed to meet the requirement of clean air in general ventilation and air conditioning system in Hospitals, Synthetic fiber industries and compressor applications.

Construction:

Media:

The media is a special synthetic non-woven bounded fiber designed to give high efficiency and long service life. It is pressed in the form of a fabric and given special treatment which prevents fungus growth. An alternative media in superior felt is also available, which gives long run trouble free services, and economical in usage.

Features:

- Efficiency : 99.9% down to 5 microns

- Pressure drop : 6.5 mm of wg. At rated flow

- Frame : Galvanized steel sheet/MS/ Aluminium/ stainless steels sheet

- Finish : Painted/ powder coated

- Filter media : Synthetic Non-woven filter media supported with HDPE mesh and Gl/aluminium Expanded mesh

- Media : Pleated

- Sealant : Available

- Type : Box type / Flange type

Customizable Precision Filtration

Fine filters can be supplied with micron ratings starting from 1 micron and mesh sizes up to 325 mesh, ensuring highly efficient removal of particulates. The filters feature customizable diameters (commonly 50 mm to 500 mm) and flow rates, making them suitable for diverse industrial processes. Stainless steel construction and various media types offer adaptability to different filtration grades and operating conditions.

Durable & Corrosion-Resistant Design

Constructed with a rugged welded stainless steel body, these filters are available in either matte or polished finishes for long-lasting performance in both standard and corrosive environments. Their robust design guarantees resistance to wear and supports a lifespan of up to five years when maintained under recommended operating conditions.

Flexible Installation & Maintenance

Installation is straightforward due to the easy-to-handle cartridge or pleated design and options for flanged or threaded end connections. Maintenance is hassle-free with manual or backwash cleaning methods, and the replaceable filter elements ensure continued high filtration efficiency without prolonged downtime.

FAQs of Fine Filters:

Q: How do I select the correct micron rating and mesh size for my fine filter application?

A: Selecting the right micron rating and mesh size depends on the specific contaminants you need to remove. Our filters can be supplied from 1 micron onwards and up to 325 mesh, offering custom solutions tailored to industrial, chemical, pharmaceutical, food & beverage, or water treatment needs. Contact our technical team for detailed application support.Q: What are the installation requirements for these fine filters?

A: Installation is designed to be simple, with options for BSP/NPT threaded or flanged end connections. The cylindrical, rugged welded design allows easy placement in most pipeline systems, and the filters can be installed in either new systems or as replacements for existing units.Q: Where are these fine filters commonly used?

A: These filters are widely used in industrial, chemical processing, pharmaceuticals, food & beverage, and water treatment sectors due to their high efficiency, corrosion resistance, and adaptability to different flow rates and pressure levels.Q: What is the typical lifespan and maintenance process for these filters?

A: Under normal operating conditions, the fine filters can last up to five years. Routine maintenance involves either manual or backwash cleaning, and replacement of the filter element when required to maintain optimal filtration efficiency.Q: What benefits do these stainless steel fine filters provide?

A: Benefits include high dust holding capacity, 99% filtration efficiency, easy installation, a long lifespan, resistance to corrosion and aggressive chemicals, and suitability for both air and liquid applications, guaranteeing reliable operation across demanding industrial environments.Q: Can these filters handle corrosive environments, and what material options are available?

A: Yes, the filters are constructed from stainless steel with either polished or matte finishes, making them highly resistant to corrosion. The filtration media can be synthetic or stainless steel mesh, depending on the application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filters-Manufacturers,Suppliers & Exporters in Category

Industrial Filters for Pharmaceutical Industries

Feature : High Durable, Corrosion Resistant, Precision Filtration, Easy Installation, Seamless Finish

Efficiency (%) : Up to 99.9%

Shape : Round / Cylindrical

Condition : New

Filter Type : Cartridge/Panel/Disc/Inline

Construction : Other, Welded/Seamless, Rigid Frame

Air Handling Unit Filter

Feature : High Dust Holding Capacity, Custom Size Available, Low Initial Pressure Drop, Washable and Reusable

Efficiency (%) : Up to 90%

Shape : Rectangular or Customized

Condition : New

Filter Type : Panel Air Filter

Construction : Other, Panel or Box Type

Microwave V Filter

Feature : Superior microwave frequency filtration, Low insertion loss, High attenuation, Precisionengineered slots

Efficiency (%) : >95% (EMI attenuation)

Shape : Vshaped filter assembly

Condition : New

Filter Type : Microwave V Filter

Construction : Other, Rugged welded fabrication, Slotted Vtype structure

Paper Paint Booth Filter

Feature : High dust holding capacity

Efficiency (%) : Up to 96%

Shape : Rectangular

Condition : New

Filter Type : Panel Filter

Construction : Other, Pleated Cardboard or Paper, Rigid structure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS