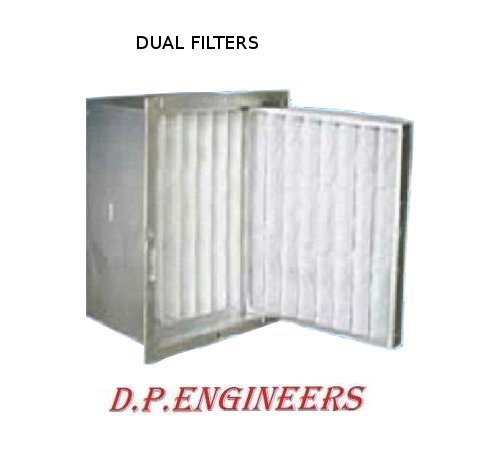

Dual Filters

Dual Filters Specification

- Temperature Range

- 5C to 80C

- Flow Rate

- 60 - 120 m/h

- Filter Type

- Dual Inline Y-strainer

- Filtration Grade

- Medium Filtration

- Capacity

- Up to 120 cubic meters/hour

- Media Type

- Water, Light Liquids

- Pressure

- Up to 10 bar

- Cleaning Method

- Manual / Backwash

- Connecting Type

- Flanged

- Efficiency (%)

- Up to 98%

- Condition

- New

- Material

- Mild Steel Body

- Mesh

- 100-200 micron stainless steel mesh

- Diameter

- 4 inch (approx.)

- Construction

- Robust welded construction with corrosion-resistant coating

- Medium Filter

- Stainless Steel Mesh

- Weight

- 18 - 22 kg (approx.)

- Shape

- Cylindrical, twin inline

- Feature

- High-efficiency filtration, easy maintenance, replaceable cartridges, dual-stage filtering system, compact design

About Dual Filters

Dual Filters

Dual Filters Comprise Of Microwave Filters and pre-filters housed in same casing that is perfectly suitable for application in limited spaces. Manufactured using the best materials procured from reputable manufacturers, the dual filters are highly acclaimed for their design and quality. The dual filters are finally encased in a galvanized sheet / aluminum / stainless steel.

Being a reliable entity, we are manufacturing, exporting and supplying a broad array of Dual Filters. The offered filters are widely used for filtration of suspended and turbidity particles. Under the visionary guidance of our experienced professionals, these filters are precisely manufactured by utilizing the high quality components with the aid of ultra-modern techniques. In addition to this, the offered Dual Filters can be availed from us at a nominal price within promised time frame.

Features:

- Sturdy construction

- Compact design

- Superior finish

- Excellent filtration capability

- Pay Mode Terms: T/T (Bank Transfer)

Versatile Installation and Durability

Designed for vertical or horizontal orientation, these dual filters suit various piping configurations. Their robust welded construction and corrosion-resistant epoxy coating ensure longevity and reliable operation in harsh industrial environments. Flanged connections in ANSI, DIN, or JIS standards allow for easy integration with existing systems.

High-Efficiency Filtration Technology

Featuring a dual-stage system with stainless steel mesh (100-200 micron), these filters deliver up to 98% efficiency in removing particulates from water or light liquids. The medium filtration grade is optimized for industrial needs, ensuring clean process runs and reduced equipment wear.

Simple Maintenance and Replacement

Maintenance is streamlined thanks to an easy manual or backwash cleaning method and replaceable filter cartridges. The recommended replacement interval is every 612 months depending on use, minimizing downtime and maintaining optimal filtration performance.

FAQs of Dual Filters:

Q: How are the Dual Inline Y-strainer Filters installed in an industrial setting?

A: The filters can be installed either vertically or horizontally, depending on your piping arrangement. Flanged end connections compatible with ANSI, DIN, or JIS standards make integration with existing setups straightforward.Q: What maintenance process is required for these dual filters?

A: Maintenance involves either manual cleaning or using the backwash feature for filter mesh, ensuring continued efficiency. Filter cartridges are replaceable, typically every 612 months, depending on the level of contaminants handled.Q: When should the filter cartridges be replaced?

A: Cartridge replacement is advised every 612 months, though it may vary based on flow rate, contaminant load, and operational conditions. Regular inspections help determine the optimal replacement frequency.Q: Where can these filters be used effectively?

A: These filters are ideal for industrial process lines, water treatment plants, and the chemical industry. Their robust construction and corrosion resistance make them suitable for demanding environments handling water and light liquids.Q: What benefits do nitrile and Viton gaskets offer in this filter system?

A: Nitrile and Viton gaskets provide excellent sealing performance, chemical resistance, and durability, helping to prevent leaks and withstand harsh media typically found in industrial and chemical processes.Q: How is high filtration efficiency achieved in this filter?

A: Efficiency of up to 98% is attained through the dual-stage design and use of fine stainless steel mesh (100200 microns), which captures particulates and ensures medium-grade filtration for cleaner process fluids.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filters-Manufacturers,Suppliers & Exporters in Category

Panel Microvee Filter

Shape : Rectangular/Panel

Filtration Grade : Other, Medium

Material : Galvanized Iron / Aluminium Frame, Synthetic Nonwoven Media

Medium Filter : Other, Microvee Media

Fine Filter Microvee Type

Shape : Rectangular/Box

Filtration Grade : Other, Fine

Material : Galvanized Steel Frame, Synthetic Media

Medium Filter : Other, Microveetype Fine Filter

Leading Supplier of AHU ( Air Handling Unit) Filter In Avadh Utopia Vapi Gujarat

Price 1250 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : BOX TYPE / FLAGE TYPE

Filtration Grade : Pre Filter

Material : Galvanized Steel, Aluminum Anodized,SS304

Medium Filter : Micro Fiber

Leading Supplier of AHU ( Air Handling Unit) Filter by Bhadrakali Temple

Price 1250 INR / Piece

Minimum Order Quantity : 24 Pieces

Shape : BOX TYPE / FLAGE TYPE

Filtration Grade : Pre Filter

Material : Galvanized Steel, Aluminum Anodized,SS304

Medium Filter : Micro Fiber

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS