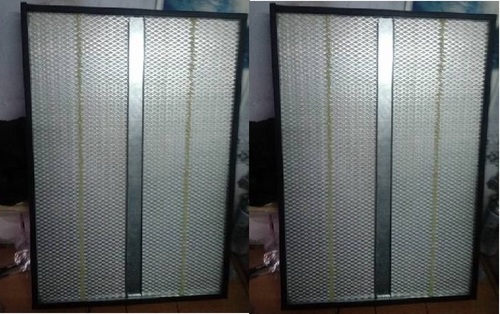

Turbine Filter

Turbine Filter Specification

- Media Type

- Stainless Steel Wire Mesh

- Cleaning Method

- Backwashable / Manual cleaning

- Temperature Range

- Up to 120C

- Connecting Type

- Flange / Threaded / Customized

- Filtration Grade

- Industrial

- Flow Rate

- 500 to 10,000 LPH

- Capacity

- Dependent on model (customized on request)

- Filter Type

- Cartridge / Mesh filter

- Efficiency (%)

- Up to 99%

- Pressure

- Up to 16 Bar

- Condition

- New

- Material

- Stainless Steel

- Mesh

- 40-400 Micron (customizable)

- Diameter

- 50 mm to 500 mm

- Construction

- Welded/Seamless

- Medium Filter

- Liquid/Air/Gas

- Weight

- 1-5 Kg (varies by model)

- Shape

- Cylindrical

- Feature

- Robust and durable design, suitable for heavy-duty turbine operation.

- Sealing

- Nitrile / Viton / EPDM Gaskets

- Colour

- Silver metallic

- Replacement Interval

- 6-12 Months depending on use

- Installation Type

- Inline

- Mounting

- Horizontal / Vertical

- Application

- Turbine protection in industrial and power generation plants

- End Connection

- Flanged, Threaded, or as per customer specification

- Packaging Type

- Export-grade wooden box or as per order

Turbine Filter Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Turbine Filter

Gas Turbine Air Intake FilterGas Turbine Air Intake Filter cartridges are modern and reliable for air intake applications.They ensure high efficient filtration of dust and other contaminants even in the most polluted environments. Normally these are made of mixture of polyester & cellulose and some time 100% polyester media.These media have much better pleat ability & dimensional stability. Pleated filter media offer high filtration efficiency, very fine retention level, easy clean ability & aesthetically good product than other normal filter media.

Features & Benefits

- Easy to clean

- All polyester materials are washable

- High flow efficiency

- High Air to cloth ratio

- Large spacing

- Cleanable without damaging filter media

- Retrofit for most standard makes

Technical Specifications

- Filter media

- Mixture of Cellulose & Polyester Media

- 100 % spun bonded polyester

Configuration

- Cylindrical

- Conical

Versatile Mounting and Connection Options

Designed for optimal adaptability, the Turbine Filter accommodates horizontal or vertical inline installation to fit diverse plant layouts. Choose from flanged, threaded, or tailor-made connections to suit specific operational requirements. The filters flexible construction ensures compatibility with a wide range of turbine systems, optimizing versatility and usability in industrial applications.

Customizable Filtration for Heavy-Duty Demands

Available in both cartridge and mesh variants, with mesh grades between 40 and 400 micron, this filter delivers industrial-grade filtration for liquids, gases, or air. Options for media type, diameter (50 to 500mm), and capacity allow customization according to plant specifications, ensuring efficient turbine protection under variable conditions.

Durable, Export-Ready Construction

Manufactured using stainless steel mesh and featuring robust welded or seamless construction, the filter stands up to demanding turbine operations. With a weight range of 1-5 kg and export-grade wooden packaging, each filter is engineered for reliable performance and secure delivery, wherever your project is located.

FAQs of Turbine Filter:

Q: How does the Turbine Filter protect equipment in industrial and power generation plants?

A: The Turbine Filter removes contaminants from liquids, gases, or air before they reach turbines, helping prevent erosion, fouling, and damage. With customizable mesh (40-400 microns) and high filtration efficiency (up to 99%), it ensures long-term turbine reliability and optimized system performance.Q: What types of connections are available for installing the Turbine Filter?

A: You can select from flanged, threaded, or custom-designed end connections to match your specific system requirements. This flexibility simplifies integration into both new and existing turbine setups across industrial applications.Q: When should the Turbine Filter be replaced for optimal performance?

A: The filter typically requires replacement every 612 months, depending on usage conditions, fluid quality, and the operating environment. Routine inspections and timely replacement support consistent filtration efficiency and turbine safety.Q: Where can the Turbine Filter be installed in my system?

A: This filter is designed for inline installation and can be mounted horizontally or vertically, providing versatile placement options that accommodate the requirements of diverse plant layouts and flow directions.Q: What is the cleaning and maintenance process for this filter?

A: The Turbine Filter can be cleaned using backwashing or manual methods, depending on the model chosen. Regular cleaning helps prolong filter life, maintain efficiency, and reduce operational downtime.Q: Which features make this filter particularly suitable for heavy-duty turbine operation?

A: Its robust stainless steel construction, high-pressure resistance (up to 16 bar), broad temperature tolerance (up to 120C), and export-ready packaging ensure durability and reliability even under intensive, continuous duty cycles.Q: What benefits does the Turbine Filter offer over standard filters?

A: Compared to typical filters, the Turbine Filter provides superior efficiency (up to 99%), customizable sizing and capacities, a choice of sealing materials, and the ability to handle a range of fluidsdelivering enhanced equipment protection and system longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Hydraulic Filter for Aquarius Pump

Filter Type : Inline Hydraulic Filter

Efficiency (%) : Up to 98%

Temperature Range : 20C to +120C

Media Type : Other, Multilayer Composite Filtering Media

Feature : Highperformance hydraulic filter for Aquarius concrete pump systems

Construction : Other, Robust Cylindrical Element with End Caps

Hydraulic Filter for 1800 Concrete Pump

Filter Type : Return line filter

Efficiency (%) : 99%

Temperature Range : 25C to +110C

Media Type : Other, Microglass/synthetic filter media

Feature : High filtration efficiency for hydraulic systems, suitable for heavyduty concrete pumps

Construction : Other, Robust cylindrical cartridge design

Mixer Hydraulic Filter

Filter Type : Hydraulic Filter

Efficiency (%) : Up to 99%

Temperature Range : 25C to 110C

Media Type : Other, Synthetic Fiber/Cellulose

Feature : High dirt holding capacity, Corrosion resistant, Easy installation

Construction : Other, Cartridge, Pleated design

Multi Layer Filter Media Folding

Filter Type : MultiLayer Media Filter

Efficiency (%) : Up to 99.99%

Temperature Range : 20C to +80C

Media Type : Other, Nonwoven Folded Media

Feature : High Dirt Holding Capacity, Uniform Thickness, Consistent Pore Size, Robust Folding Structure, Multi Layer Filtration

Construction : Other, MultiLayer Folding, Pleated Design

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free