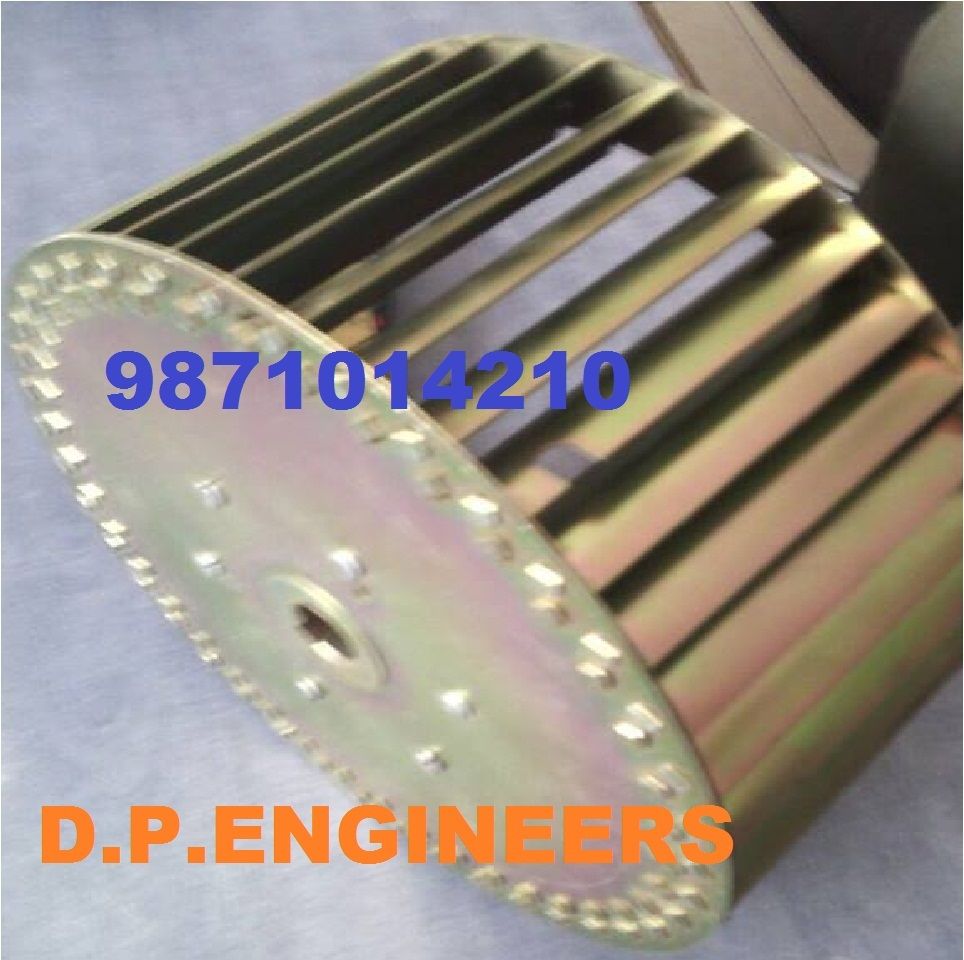

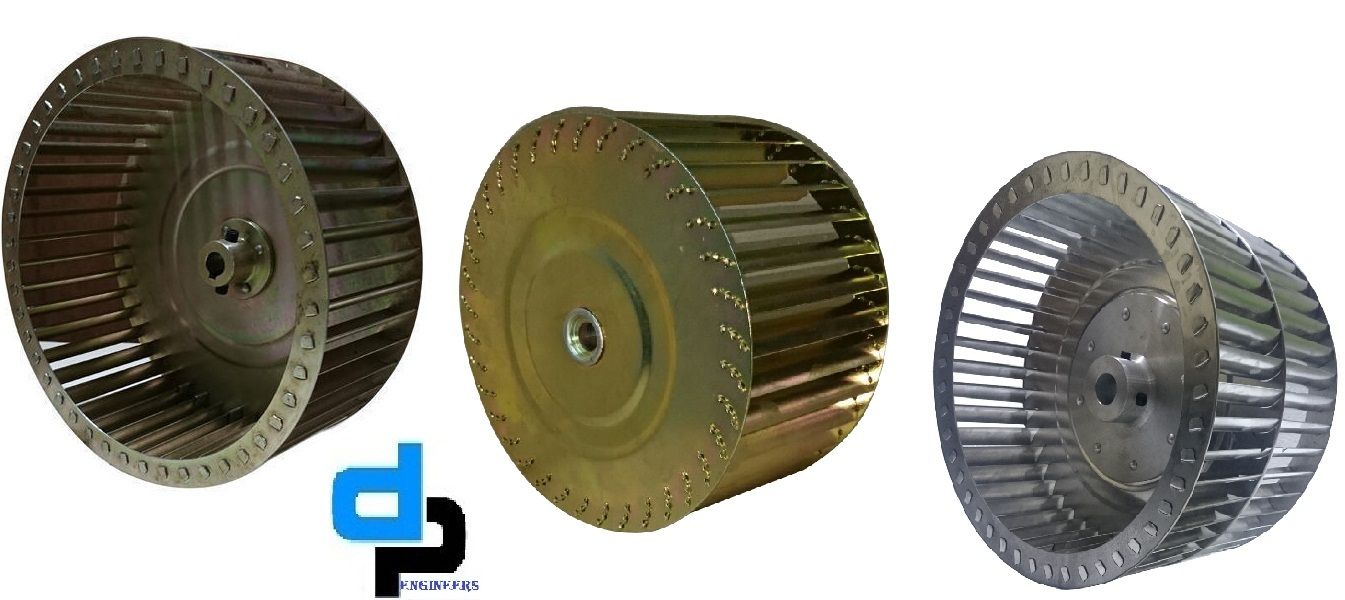

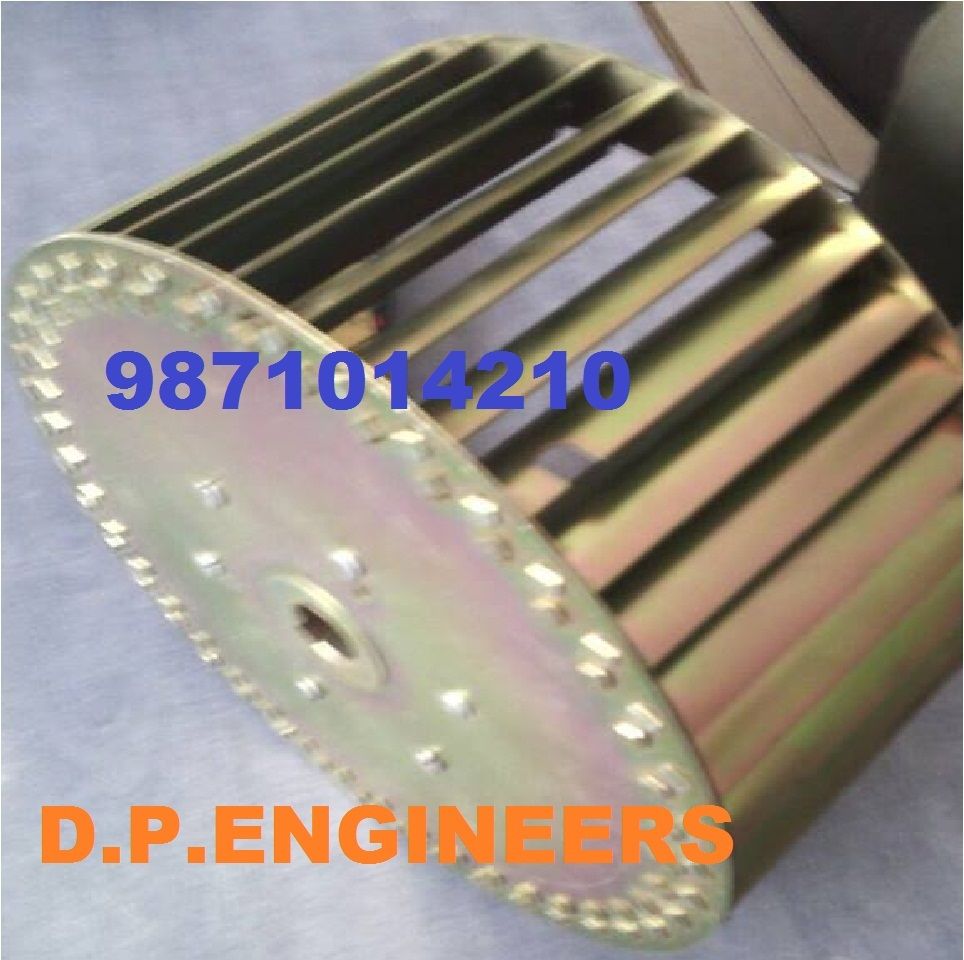

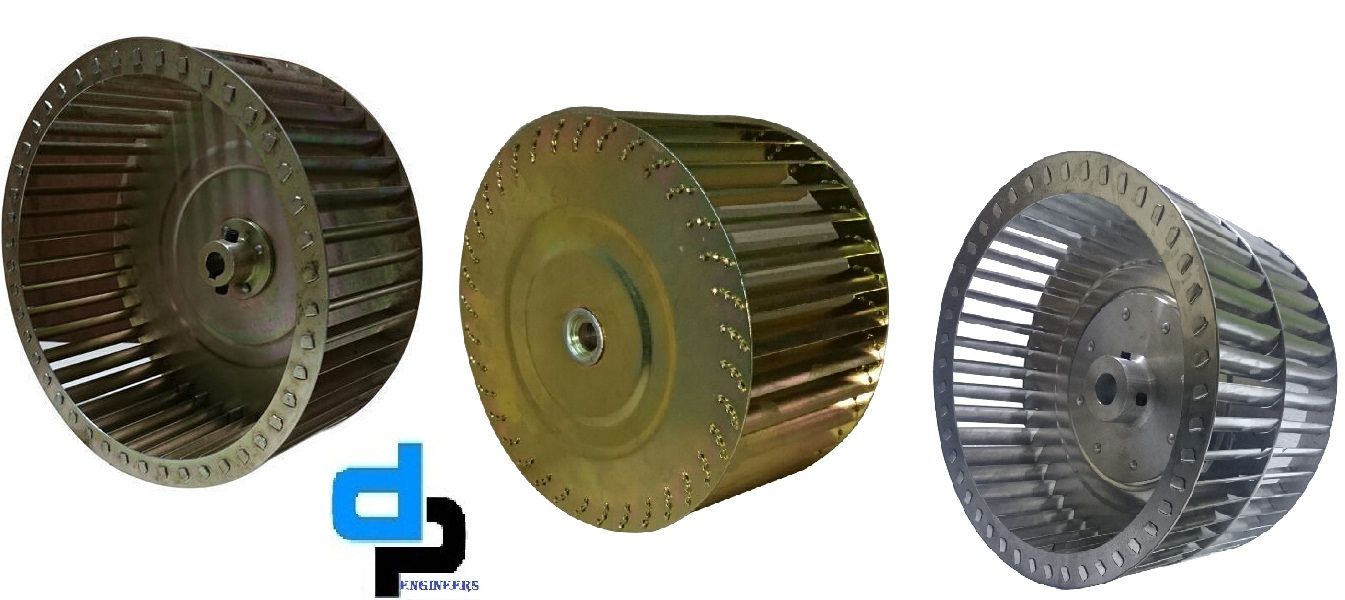

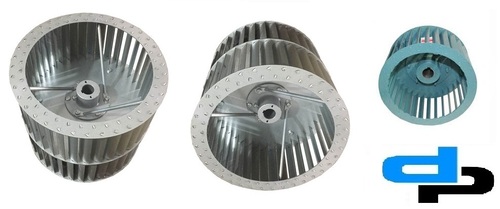

ISW Centrifugal Blower 100 MM X 63 MM

ISW Centrifugal Blower 100 MM X 63 MM Specification

- Pressure Range

- 50-100 mm (WG)

- Motor Power

- 180-370 W

- Output Power

- 180-370 W

- Life Span

- 8-10 Years

- Flow Rate

- 400-600 m/h

- Power

- 0.25 HP - 0.5 HP

- Max Pressure

- 100 mm (WG)

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 400-600 m/h

- Pressure

- 50 mm to 100 mm (WG)

- Application

- Industrial Ventilation, Exhaust, Air Cooling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Low (<75 dB)

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- Approx. 5-7 kg

- Dimension (L*W*H)

- 100 mm x 63 mm

- Color

- Grey

ISW Centrifugal Blower 100 MM X 63 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Tripura, Manipur, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Meghalaya, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Mizoram, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Haryana, Gujarat, Maharashtra, Delhi, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Karnataka, All India

About ISW Centrifugal Blower 100 MM X 63 MM

ISW Centrifugal Blower 100 MM X 63 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 1 | DP 4 25 | 100 X 63 X 75 | 4 X 2.5 | 6 & 8 MM | AL. / GI. |

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Efficient Industrial Air Handling

The ISW Centrifugal Blower provides high-capacity air movement with a forward-curved impeller designed from dynamically balanced mild steel. Suitable for demanding industrial environments, it ensures efficient ventilation and exhaust while maintaining low noise levels. Its durable construction and sealed ball bearings deliver long service life even under continuous operation.

Versatile Usage & Reliable Performance

Ideal for air cooling, exhaust, and ventilation purposes, this blower supports varied applications such as factories, workshops, and process industries. The optional VFD speed control accommodates customized airflow, and the robust TEFC enclosure guarantees protected and stable functioning across diverse conditions.

FAQs of ISW Centrifugal Blower 100 MM X 63 MM:

Q: How is the ISW Centrifugal Blower installed and operated in industrial settings?

A: The blower is base-mounted, enabling secure placement on firm surfaces. Installation should follow standard electrical safety procedures, connecting to a 220-240 V single-phase supply. Operation parameters, including speed, can be adjusted with an optional VFD to fit your specific airflow requirements.Q: What are the benefits of using a forward curved impeller in this blower?

A: Forward curved impellers, crafted from dynamically balanced mild steel, produce higher airflow with lower noise. This design ensures efficient ventilation and exhaust processes while maintaining structural stability and performance over prolonged use.Q: When should this centrifugal blower be used for ventilation or exhaust applications?

A: Deploy the ISW Centrifugal Blower when you require consistent air circulation, cooling, or removal of fumes in industrial environments. Its capacity (400-600 m/h) and pressure range (50-100 mm WG) make it suitable whenever high-efficiency ventilation or controlled exhaust is needed.Q: Where can the blower be utilized for optimal results?

A: This blower is ideal for installation in factories, manufacturing plants, workshops, or process-oriented facilities in Guyana and similar industrial setups, where continuous airflow and low noise are critical for operational efficiency and comfort.Q: What is the process for speed control on this blower?

A: The speed of the blower can be precisely adjusted using an optional Variable Frequency Drive (VFD). This allows operators to change the motor speed to match required airflow, leading to improved energy efficiency and extending the equipments lifespan.Q: What maintenance is required for the ISW Centrifugal Blower?

A: Minimal routine maintenance is necessary due to its sealed ball bearing design. Regular inspections for dust accumulation and checking the TEFC enclosure for integrity will ensure optimal continuous operation and longevity.Q: What advantage does the TEFC enclosure provide for this blower?

A: The Totally Enclosed Fan Cooled (TEFC) enclosure secures the motor against environmental factors such as dust and moisture, enhancing safety, reliability, and extending the working life of the blower in harsh industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 330 MM X 125 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Color : Grey

Motor Power : 1 HP

Life Span : 10 Years (under standard operating conditions)

SISW Centrifugal Blower 125 MM X 63 MM

Price 600 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Color : Silver Grey

Motor Power : 0.37 kW

Life Span : 10 Years

SISW Centrifugal Blower 610 MM X 250 MM

Price 16000 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Color : Blue

Motor Power : 3.7 kW

Life Span : 15 Years (under standard conditions)

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Material : other , Mild Steel

Color : Blue/Grey

Motor Power : 0.371.1 kW

Life Span : 810 Years

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS