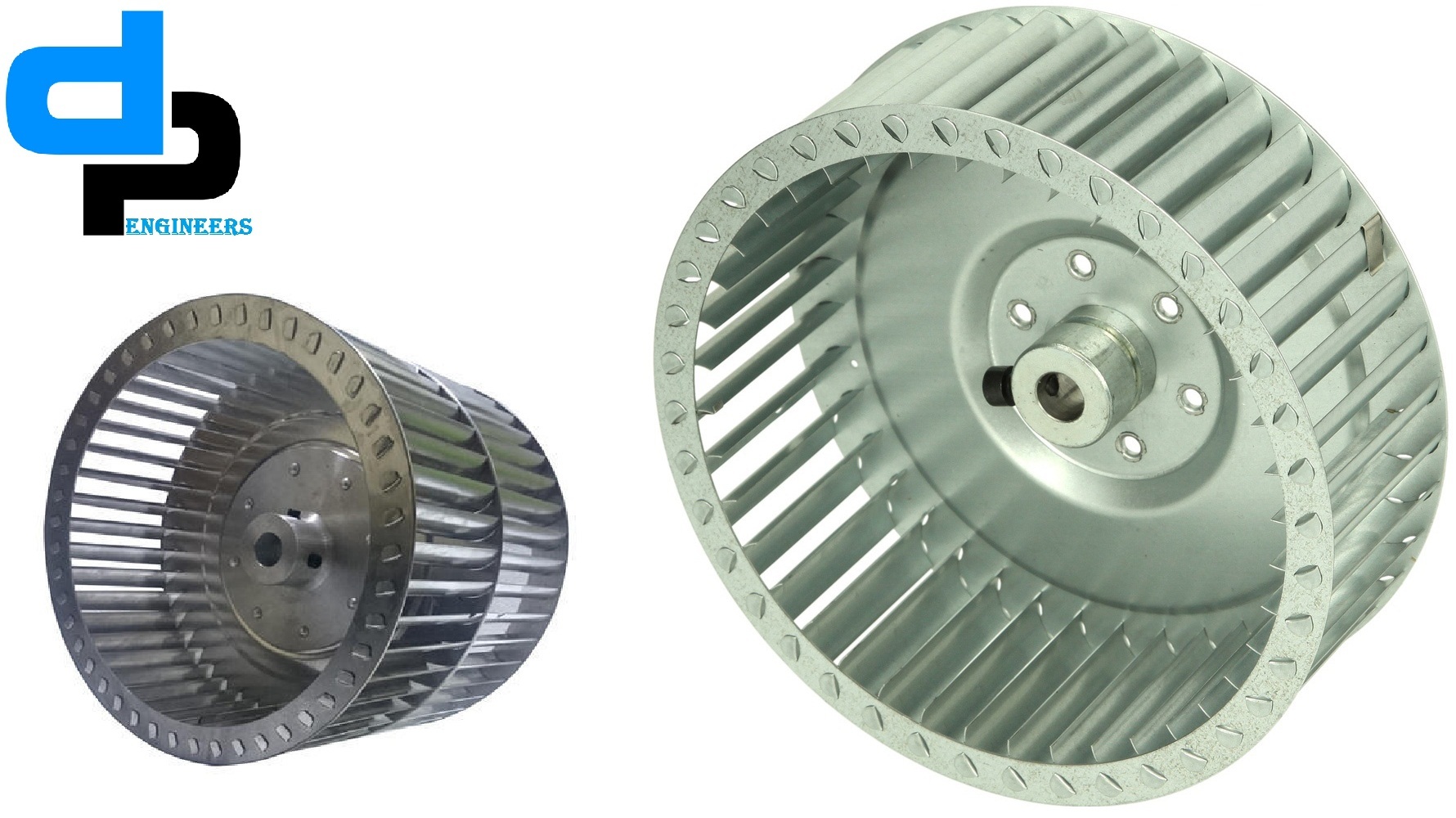

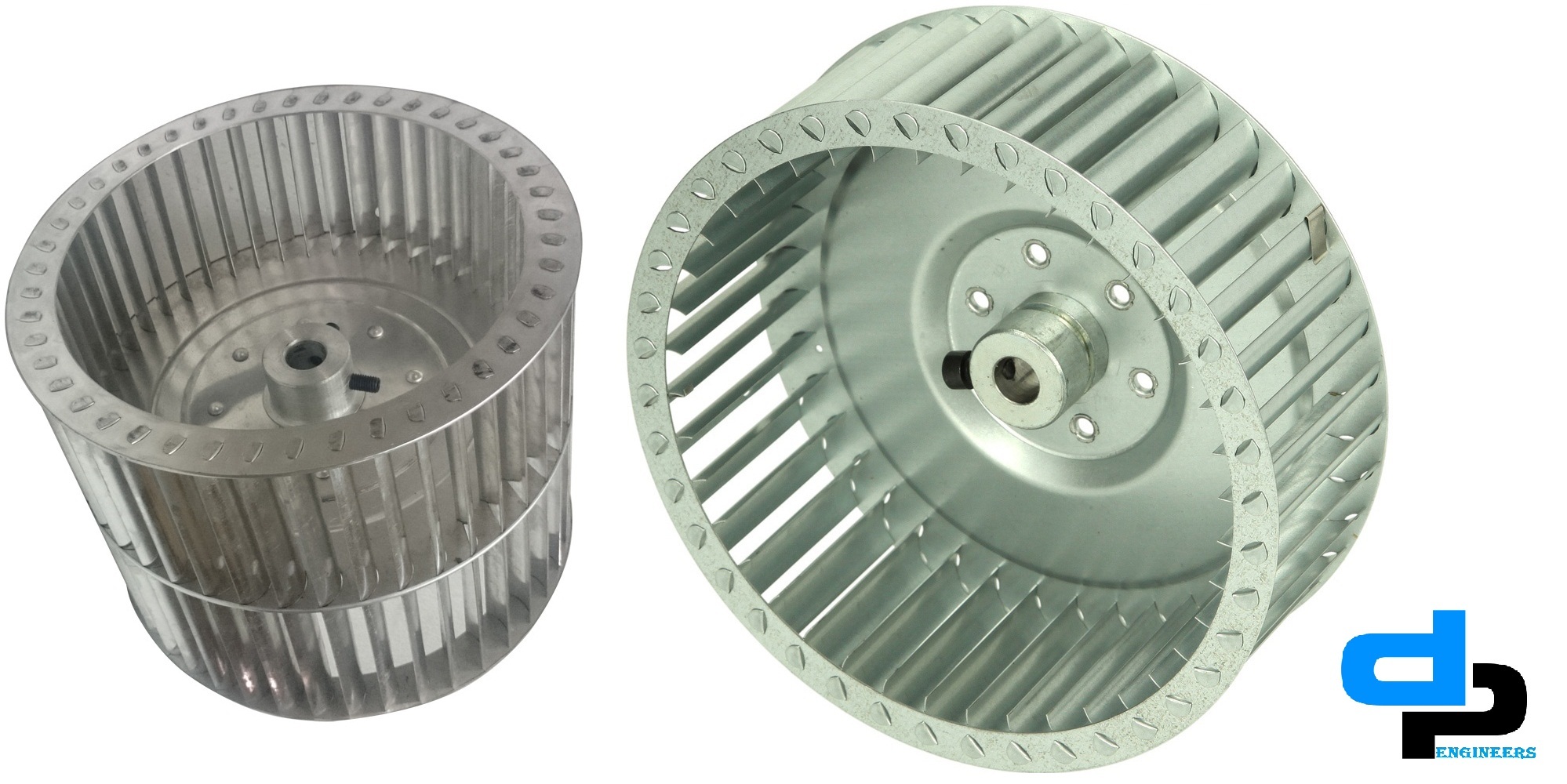

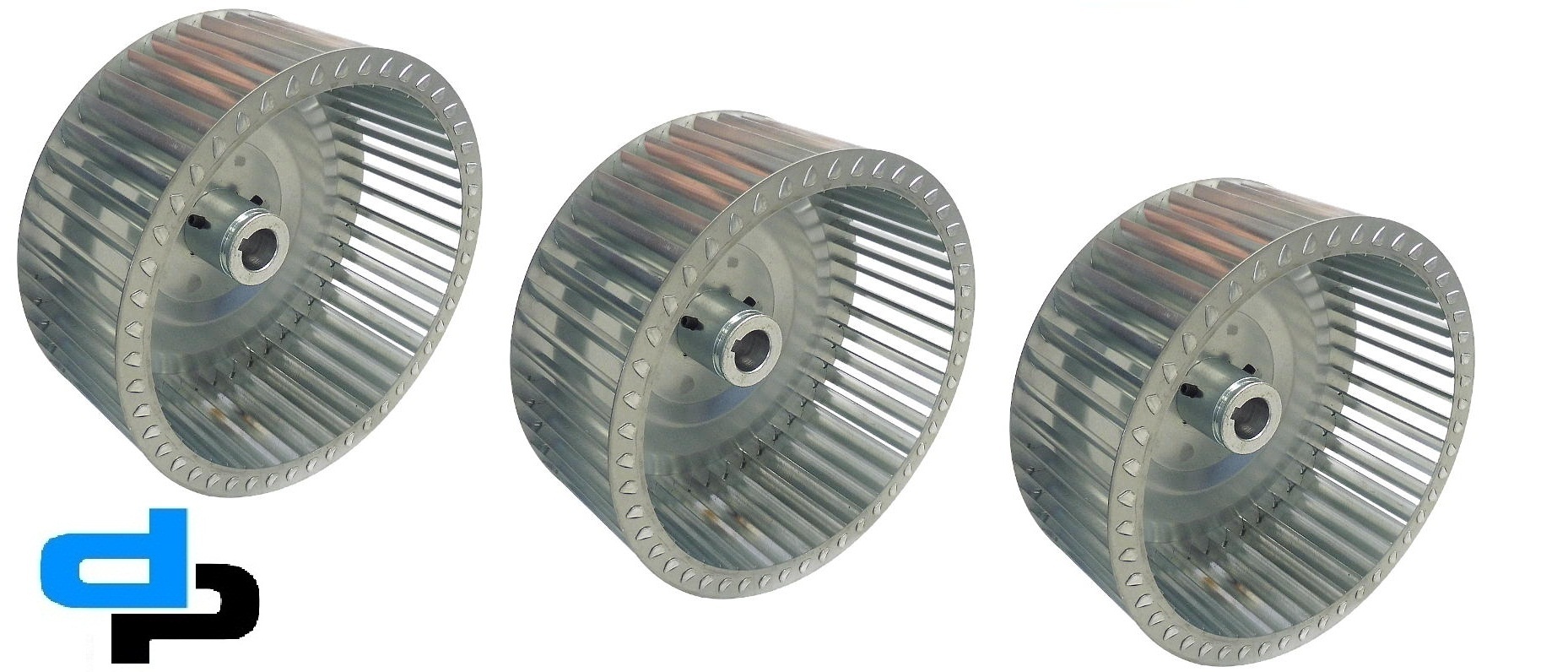

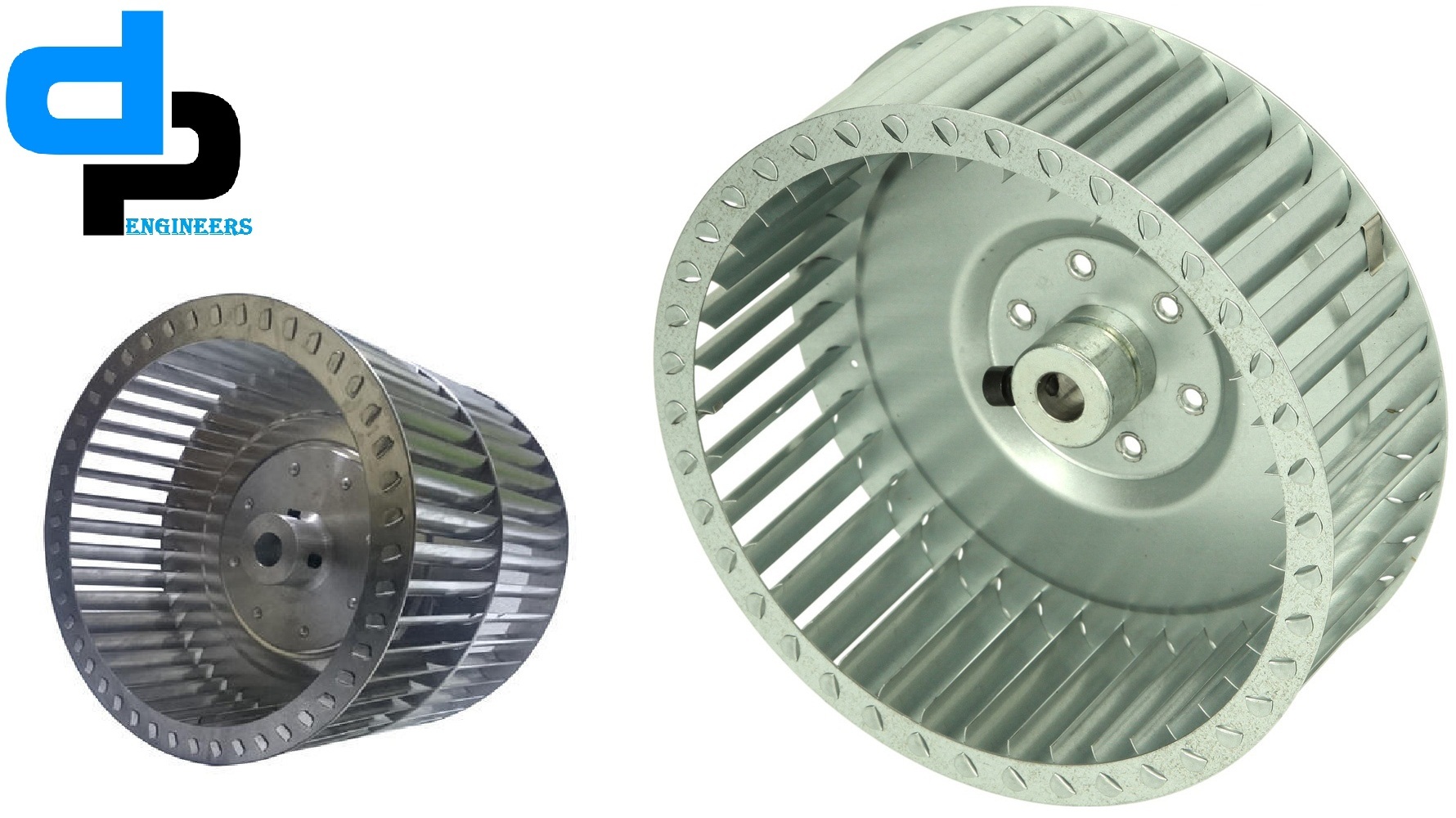

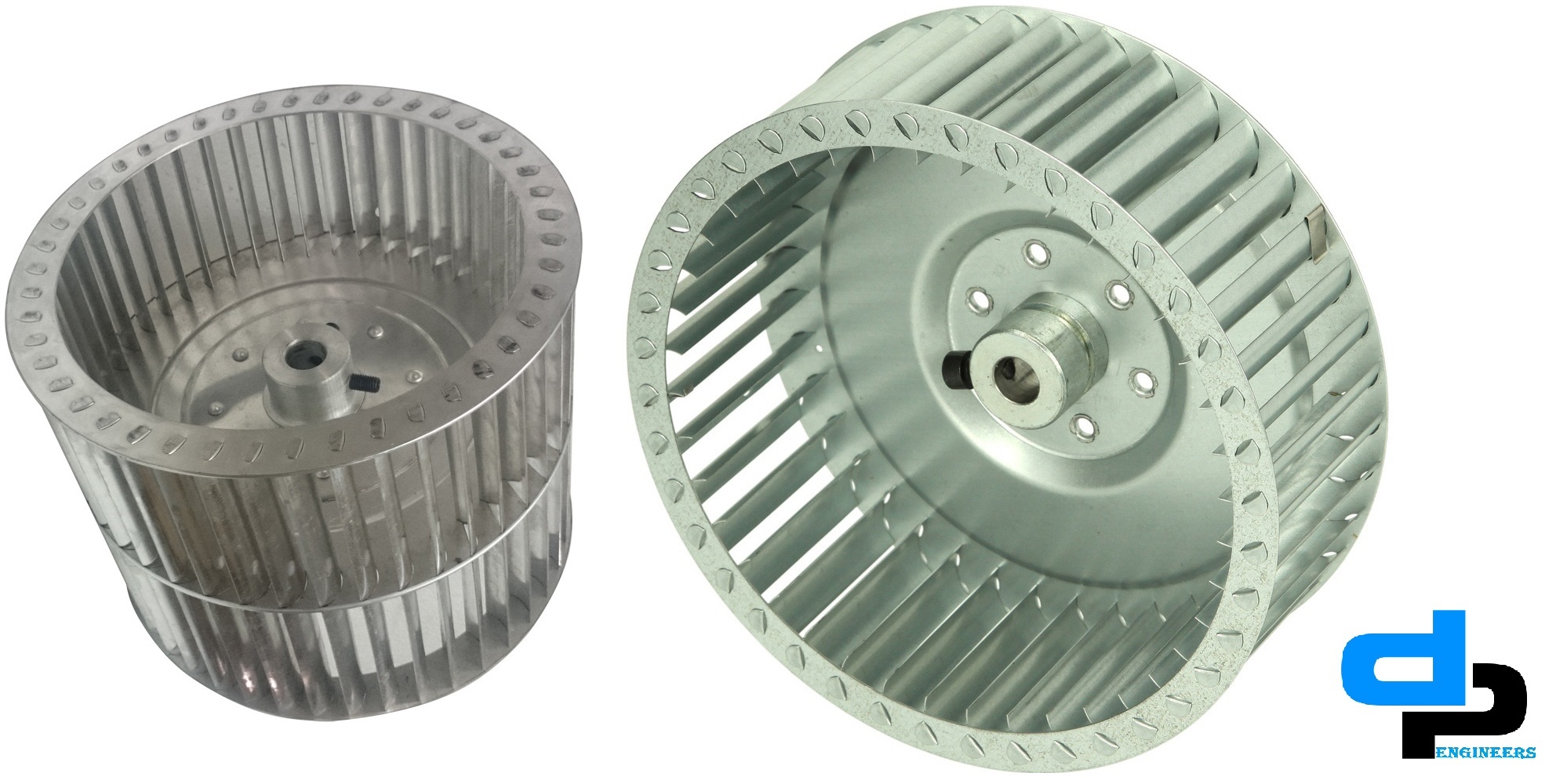

SISW Centrifugal Blower 530 MM X 150 MM

SISW Centrifugal Blower 530 MM X 150 MM Specification

- Motor Power

- 2.2 - 3.7 kW

- Life Span

- 8-10 years (typical with maintenance)

- Flow Rate

- 2300 to 6100 m3/hr

- Power

- 3-5 HP

- Output Power

- 2.2 - 3.7 kW

- Max Pressure

- 450 mmWG

- Pressure Range

- 180-450 mmWG

- Product Type

- SISW (Single Inlet Single Width) Centrifugal Blower

- Material

- Mild Steel (MS), Powder Coated

- Capacity

- 2300-6100 m3/hr

- Pressure

- 180-450 mmWG

- Application

- Industrial ventilation, Air handling units, Dust/fume extraction

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- < 78 dB(A)

- Power Source

- Electric

- Voltage

- 220-415V AC

- Weight

- Approx. 38-52 kg

- Dimension (L*W*H)

- 530 mm x 150 mm (Wheel Size)

- Color

- Blue

SISW Centrifugal Blower 530 MM X 150 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Manipur, Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Delhi, Gujarat, Haryana, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About SISW Centrifugal Blower 530 MM X 150 MM

SISW Centrifugal Blower 530 MM X 150 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 35 | DP 21 60 | 530 X 150 X 430 | 21 X 6 | 40 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

High-Performance Air Handling

The SISW Centrifugal Blower is tailored for efficient air movement in industrial settings. Its backward curved impeller and dynamic balance ensure optimized airflow and pressure, supporting applications such as ventilation, dust removal, and fume extraction. The TEFC motor enclosure and powder-coated finish enhance longevity and withstand rigorous operation conditions.

Customizable Installation Options

This blower accommodates varying installation needs with a base frame-mounted design and flexible drive optionschoose between direct or V-belt drive to suit your operational requirements. Discharge positioning (top or side) and a versatile inlet size facilitate seamless integration into diverse industrial setups.

FAQs of SISW Centrifugal Blower 530 MM X 150 MM:

Q: How is the SISW Centrifugal Blower installed for industrial applications?

A: The blower is base frame mounted, allowing for secure and stable installation in industrial environments. Discharge can be oriented either at the top or side, as required, to fit into existing ductwork and systems.Q: What are the benefits of the backward curved impeller design?

A: The backward curved impeller increases efficiency by reducing turbulence and noise while delivering higher airflow at lower energy consumption. This design is ideal for ventilation, air handling units, and extraction systems.Q: When should I choose direct drive or V-belt drive configurations?

A: Direct drive is preferred for lower maintenance and more compact installations, while V-belt drive offers flexibility in speed and power adaptation, suitable when you require variable performance for different applications.Q: Where can this blower be effectively used?

A: Its designed for industrial settings such as manufacturing plants, warehouses, HVAC systems, and dust/fume extraction processes, offering reliable and efficient air movement under demanding conditions.Q: What is the maintenance process for ensuring a long service life?

A: Regular maintenance involves routine inspection of bearings, drive systems, motor integrity, and cleaning to prevent dust buildup. Adhering to a maintenance schedule can extend the blowers operational life to 8-10 years.Q: How does the TEFC enclosure benefit blower operation?

A: The Totally Enclosed Fan Cooled (TEFC) enclosure protects the motor from dust, debris, and moisture, enhancing reliability and reducing the risk of electrical or mechanical failures in harsh industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 125 MM X 63 MM

Price 600 INR

Minimum Order Quantity : 5 Pieces

Life Span : 10 Years

Frequency (MHz) : 50 Hz

Capacity : 250 m/h

Motor Speed : 2800 RPM

SISW Centrifugal Blower 150 MM X 50 MM

Price 650 INR

Minimum Order Quantity : 5 Pieces

Life Span : 57 Years

Frequency (MHz) : 50 Hz

Capacity : 300 m/hr

Motor Speed : 2800 RPM

SISW Centrifugal Blower 250 MM X 75 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Life Span : 15 Years (approx)

Frequency (MHz) : 50 Hz

Capacity : 600 CFM

Motor Speed : 2800 RPM

SISW Centrifugal Blower 610 MM X 150 MM

Price 15000 INR

Minimum Order Quantity : 5 Pieces

Life Span : 10 Years

Frequency (MHz) : 50 Hz

Capacity : 2500 CFM

Motor Speed : 1440 RPM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS