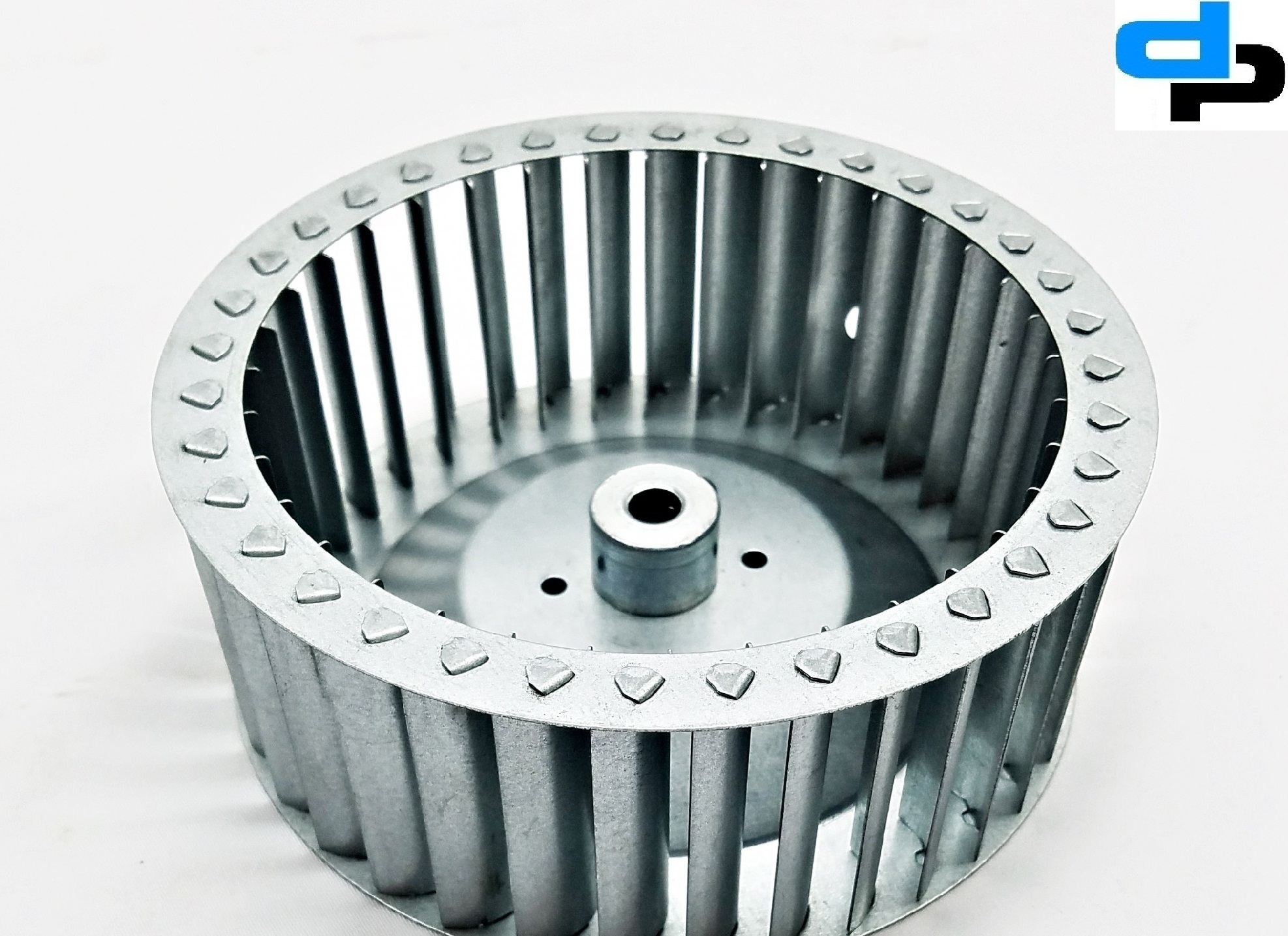

SISW Centrifugal Blower 455 MM X 180 MM

SISW Centrifugal Blower 455 MM X 180 MM Specification

- Pressure Range

- 150-200 mm WG

- Life Span

- 8-10 years with routine maintenance

- Motor Power

- 2 HP (Standard)

- Max Pressure

- 200 mm WG

- Power

- 1.5 - 3.0 kW

- Output Power

- 1.5 - 3.0 kW

- Flow Rate

- 2000-4000 m/hr

- Product Type

- SISW (Single Inlet Single Width) Centrifugal Blower

- Material

- Mild Steel / Stainless Steel

- Capacity

- 2000-4000 m/hr

- Pressure

- 150-200 mm WG

- Application

- Ventilation, Air Handling, Industrial Exhaust, HVAC, Dust/Fume Extraction, etc.

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- 72-78 dB(A)

- Power Source

- Electric

- Voltage

- 220-415 V AC

- Weight

- Approx. 45-60 kg (depending on build)

- Dimension (L*W*H)

- 455 mm x 180 mm (Impeller Size), Overall dimensions vary by model

- Color

- Silver/Grey

SISW Centrifugal Blower 455 MM X 180 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Assam, Dadra and Nagar Haveli, Chandigarh, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Arunachal Pradesh, Bihar, Delhi, Daman and Diu, Goa, Himachal Pradesh, Jammu and Kashmir, Kerala, Lakshadweep, Madhya Pradesh, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Manipur, Uttarakhand, Uttar Pradesh, Gujarat, Maharashtra, Haryana, Karnataka, Central India, Jharkhand, Chhattisgarh, All India

About SISW Centrifugal Blower 455 MM X 180 MM

SISW Centrifugal Blower 455 MM X 180 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 33 | DP 18 70 | 455 X 180 X 365 | 18 X 7 | 35 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS

Versatile Drive and Mounting Options

The SISW Centrifugal Blower offers flexibility in both drive and mounting. Choose between belt or direct drive systems and customize impeller type (backward or forward curved) to suit specific industrial needs. The base-mounted construction provides stability and straightforward installation, supporting a wide range of airflow and pressure requirements.

Durable and Reliable Performance

Built for longevity, the blower uses high-quality mild steel or stainless steel, powder-coated or painted for superior corrosion resistance. Equipped with heavy-duty ball bearings and class F or higher insulation, it delivers safe, stable, and quiet operation. Dynamically balanced rotors minimize vibration, ensuring extended service life with consistent performance.

FAQs of SISW Centrifugal Blower 455 MM X 180 MM:

Q: How is the SISW Centrifugal Blower typically installed?

A: The blower is base mounted, allowing for secure and stable installation on flat surfaces. Customized mounting options are available to address specific site requirements, making it suitable for a variety of industrial settings.Q: What industrial environments are ideal for this centrifugal blower?

A: This blower is well-suited for HVAC systems, industrial exhaust setups, air handling, and dust or fume extraction tasks. Its robust construction and customizable features make it appropriate for factories, warehouses, and process industries.Q: When is maintenance required, and how does it impact service life?

A: Regular maintenance is suggested according to the manufacturers schedule to maximize performance. With routine servicing of bearings and motor components, the blower can provide a service life of 8-10 years.Q: What are the benefits of choosing backward or forward curved impellers?

A: Backward curved impellers offer higher efficiency and lower noise, suitable for energy-conscious applications. Forward curved impellers deliver higher airflow at lower speeds, making them ideal where volume is prioritized over pressure.Q: Where can the SISW Centrifugal Blower be used for optimum performance?

A: Optimum performance is achieved in environments ranging from industrial manufacturing floors to large commercial ventilation systems. The blower handles temperatures from -10C to +80C and is resistant to corrosion, supporting use in diverse settings.Q: What are the available customization and control options?

A: Customers can choose direct or belt drive systems, impeller type, casing finish, and inlet sizes tailored to their process needs. An optional control panel can be provided on request for enhanced monitoring and operational control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 200 MM X 75 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 30 to 60 mm WG

Color : Silver/Gray

Power : 0.5 HP

Dimension (L*W*H) : 200 mm x 75 mm

ISW Centrifugal Blower 100 MM X 63 MM

Price 550 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 50100 mm (WG)

Color : Grey

Power : 0.25 HP 0.5 HP

Dimension (L*W*H) : 100 mm x 63 mm

SISW Centrifugal Blower 200 MM X 100 MM

Price 1050 INR

Minimum Order Quantity : 7 Pieces

Pressure Range : 60100 mm WC

Color : Blue

Power : 0.75 HP

Dimension (L*W*H) : 200 mm x 100 mm x 220 mm

SISW Centrifugal Blower 455 MM X 150 MM

Price 9000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 60120 mm WG

Color : Blue

Power : 2 HP

Dimension (L*W*H) : 455 mm x 150 mm x 350 mm (Approx)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS