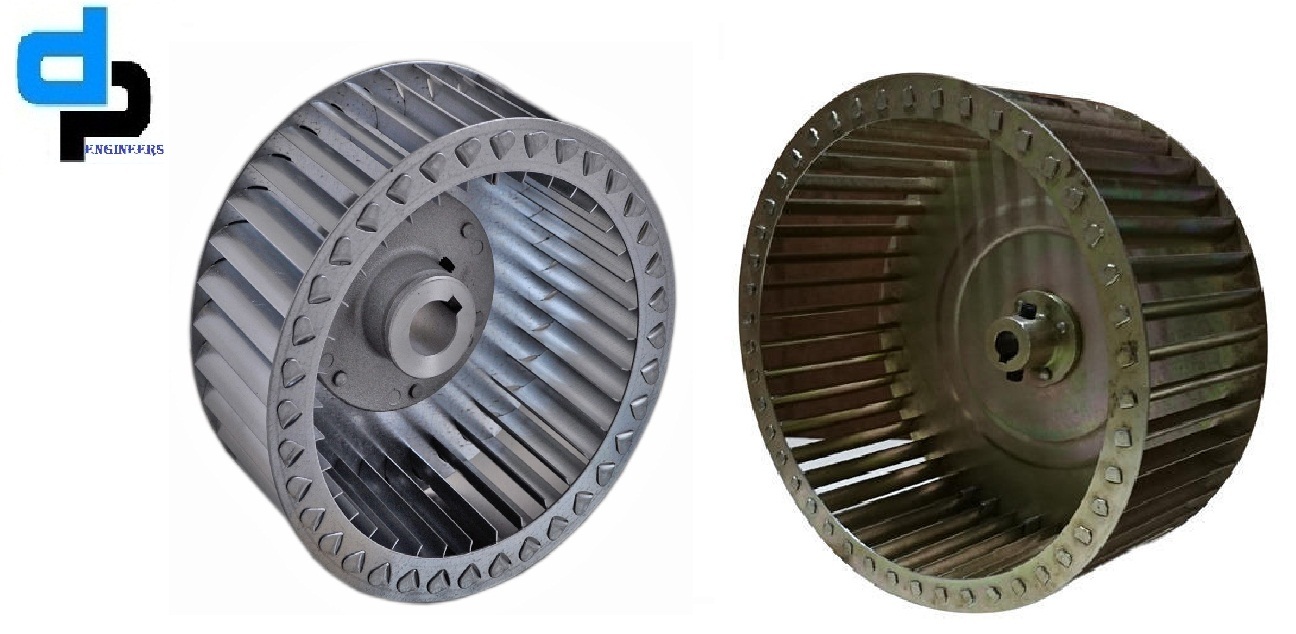

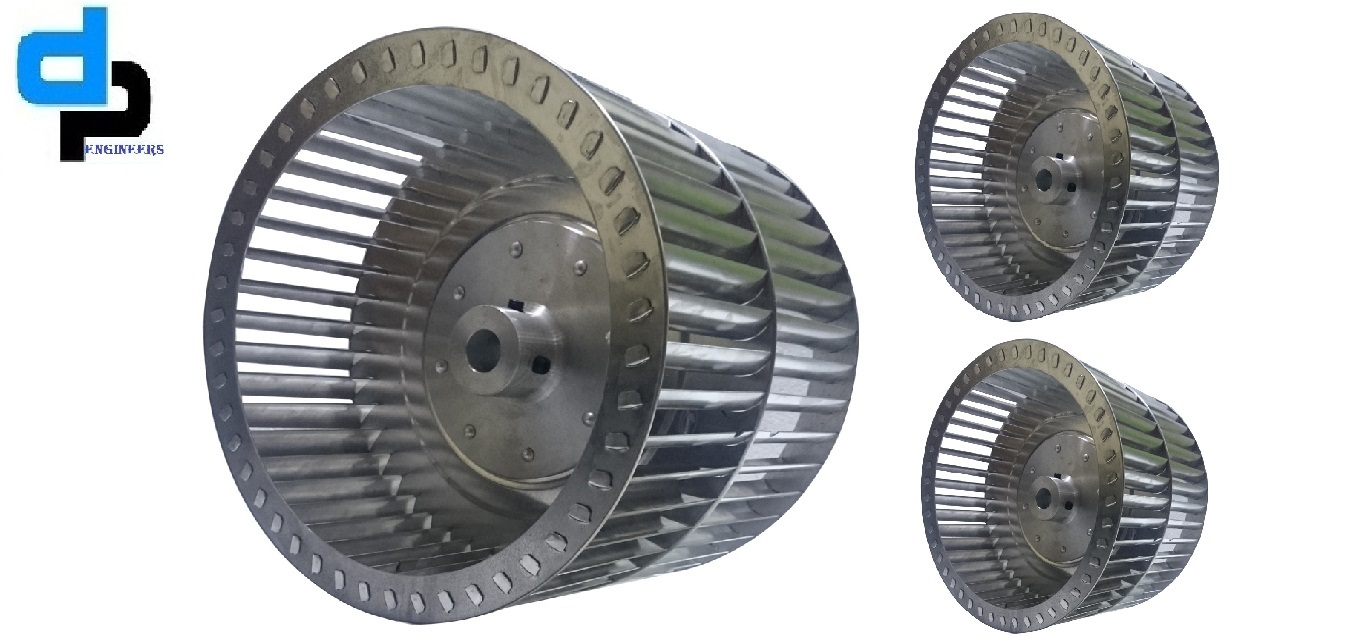

SISW Centrifugal Blower 250 MM X 100 MM

SISW Centrifugal Blower 250 MM X 100 MM Specification

- Life Span

- Over 5 Years (typical)

- Max Pressure

- 70 mm WC

- Motor Power

- 0.37 kW 1.1 kW

- Flow Rate

- 500-1100 m/hr

- Output Power

- 0.37 kW 1.1 kW

- Power

- 0.5 HP 1.5 HP

- Pressure Range

- 10 70 mm WC

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 500-1100 m/hr

- Pressure

- Up to 70 mm WC

- Application

- Ventilation, Exhaust, Cooling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- < 75 dB

- Power Source

- Electric

- Voltage

- 220-415 V AC

- Weight

- Approx. 17 kg

- Dimension (L*W*H)

- 250 mm x 100 mm (Impeller size)

- Color

- Grey

SISW Centrifugal Blower 250 MM X 100 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Manipur, Nagaland, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Central India, Jharkhand, Chhattisgarh, All India

About SISW Centrifugal Blower 250 MM X 100 MM

SISW Centrifugal Blower 250 MM X 100 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| | OD X HT X ID | OD X HT | MM & INCHES | ||

| 20 | DP 10 40 | 250 X 100 X 210 | 10 X 4 | 12.70 MM ( 1/2'' ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Versatile Applications and Robust Construction

Specifically built for industrial environments, the SISW Centrifugal Blower serves as a dependable solution for general ventilation, air handling units, exhaust operations, and cooling systems. Its heavy-duty, mild steel impeller ensures dynamic balance and longevity, while the grey, class F-insulated body enhances safety and durability under diverse working conditions.

Efficient Performance with Simple Maintenance

Operating at up to 80% static efficiency, the blower delivers strong airflow while maintaining low noise levels. The base-mounted design allows for stable installation, and ample serviceability is provided through easily available maintenance and replacement parts. Direct or belt drive compatibility offers flexibility for various industrial setups.

FAQs of SISW Centrifugal Blower 250 MM X 100 MM:

Q: How is the SISW Centrifugal Blower 250 MM X 100 MM typically installed in industrial settings?

A: This blower is base-mounted for stability, allowing straightforward integration into existing ventilation or air handling systems. It supports both direct and belt drive methods, making it adaptable to diverse equipment arrangements and requirements.Q: What are the main benefits of using a dynamically balanced mild steel impeller?

A: A dynamically balanced impeller minimizes vibrations, ensuring smoother operation and enhancing both efficiency and the blowers operational life. Mild steel construction adds mechanical strength and resistance to wear in industrial environments.Q: When should maintenance or parts replacement be performed on this blower?

A: Routine maintenance should follow the manufacturers guidelines, typically including periodic checks of bearings and the impeller. Thanks to the easy-maintenance design and readily available spare parts, servicing can be conducted efficiently during regular equipment downtimes.Q: Where can this blower be effectively utilized?

A: The SISW Centrifugal Blower is suitable for industrial spaces requiring reliable ventilation, such as manufacturing floors, AHUs, or large exhaust systems. Its robust construction handles ambient temperatures up to 60C, making it ideal for Indian manufacturing and export facilities.Q: What process is involved in ensuring the blower delivers optimal airflow and efficiency?

A: Optimal performance is achieved by selecting the suitable mounting, aligning the direct or belt drive properly, and ensuring the electrical parameters (voltage, frequency) match specifications. The blowers dynamically balanced impeller and heavy-duty bearings play a crucial role in maintaining consistent, efficient operation.Q: How does this product support quiet operation despite high performance?

A: Engineered for a noise level below 75 dB, the blower incorporates aerodynamic design in its forward-curved impeller and robust housing. Quality ball bearings further reduce operational noise, making it suitable for use where sound control is essential.Q: What are the advantages of the blowers service-friendly design for long-term industrial use?

A: Easy access to maintenance points and the availability of replacement parts assure minimum downtime. With over a 5-year typical lifespan, this design approach leads to reduced operational interruptions and lower long-term maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 125 MM X 63 MM

Price 600 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 400600 Pa

Motor Power : 0.37 kW

Max Pressure : 600 Pa

Capacity : 250 m/h

SISW Centrifugal Blower 330 MM X 125 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 80120 mm WG

Motor Power : 1 HP

Max Pressure : 120 mm WG

Capacity : 10001200 m/hr

SISW Centrifugal Blower 250 MM X 75 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 50100 mm WC

Motor Power : 0.75 kW

Max Pressure : 100 mm WC

Capacity : 600 CFM

SISW Centrifugal Blower 230 MM X 90 MM

Price 1100 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 4001200 Pa

Motor Power : 0.37 kW

Max Pressure : 1200 Pa

Capacity : 375420 CFM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS