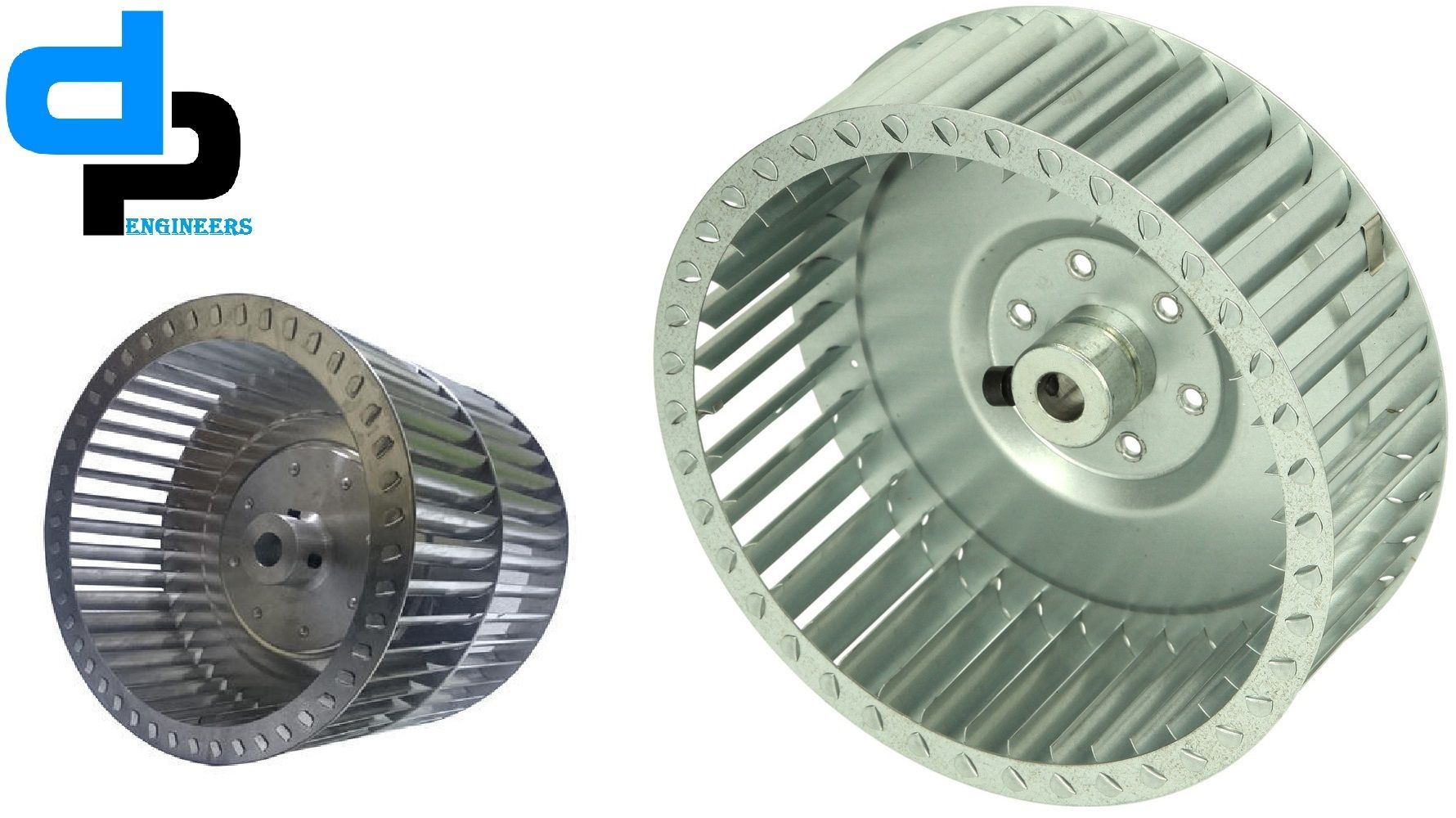

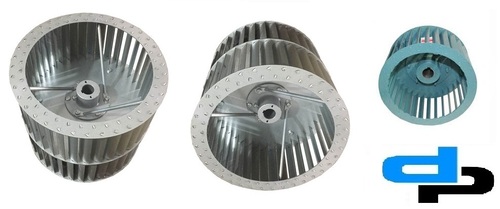

SISW Centrifugal Blower 230 MM X 90 MM

SISW Centrifugal Blower 230 MM X 90 MM Specification

- Max Pressure

- 1200 Pa

- Life Span

- 10+ Years under normal operating conditions

- Motor Power

- 0.37 kW

- Flow Rate

- 375-420 CFM

- Output Power

- 0.37 kW

- Pressure Range

- 400-1200 Pa

- Power

- 0.25 HP to 0.5 HP

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel, Powder Coated

- Capacity

- 375-420 CFM

- Pressure

- 400-1200 Pa

- Application

- Air Ventilation, HVAC, Industrial Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 78 dB

- Power Source

- Electric

- Voltage

- 220-240 V AC

- Weight

- Approx. 7-9 Kg

- Dimension (L*W*H)

- 230 mm x 90 mm

- Color

- Silver Grey

SISW Centrifugal Blower 230 MM X 90 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Manipur, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, Karnataka, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About SISW Centrifugal Blower 230 MM X 90 MM

SISW Centrifugal Blower 230 MM X 90 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 16 | DP 9 35 | 230 X 90 X 190 | 9 X 3.5 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

Optimized Performance for Industrial Needs

This centrifugal blower excels in demanding environments, thanks to its powder-coated mild steel construction and direct-driven design. Its dynamically balanced impeller ensures vibration-free operation, while the pillow block or sealed ball bearings enhance durability. Suitable for commercial ventilation, air conditioning, and industrial exhaust applications, its clockwise or counterclockwise rotation offers versatile installation options.

Low Maintenance and High Efficiency

With a robust motor power of 0.37 kW and a flow rate of up to 420 CFM, the blower maintains energy-efficient operation. The rectangular outlet design ensures optimized air discharge, while the direct-drive mechanism reduces maintenance requirements. Engineered to operate at temperatures between -10C and +55C, it supports continuous, reliable performance in various industrial settings.

FAQs of SISW Centrifugal Blower 230 MM X 90 MM:

Q: How does the SISW Centrifugal Blower support industrial fume exhaust and HVAC systems?

A: The blower is engineered with backward curved blades and a dynamically balanced impeller, which facilitate efficient removal of fumes and effective air circulation. Its direct-driven design and adaptable rotation directions make it suitable for varied layouts in industrial ventilation and air conditioning.Q: What materials are used in the construction of this centrifugal blower?

A: The impeller is constructed from mild steel, dynamically balanced for stability, and the entire assembly is powder-coated. This ensures corrosion resistance and durability for long-term industrial usage.Q: When should I choose the pillow block over sealed ball bearings for mounting?

A: Pillow block bearings are ideal for applications requiring higher ease of maintenance or operation under heavier loads, while sealed ball bearings are better suited for environments where minimal maintenance and higher protection from contaminants are needed.Q: Where can the SISW Centrifugal Blower be installed?

A: This blower is base mounted, allowing installation in industrial fume extraction points, air conditioning systems, commercial ventilation ducts, and other environments demanding reliable air movement and exhaust.Q: What routine maintenance is required for optimal performance?

A: Routine maintenance includes regular checking of bearings, cleaning of the impeller blades and housing, and ensuring electrical connections remain secure. The robust design minimizes frequent servicing, but scheduled checks are recommended for longevity.Q: How does the blowers direct-driven system benefit users?

A: The direct-driven configuration eliminates the need for belts or pulleys, reducing mechanical losses, enhancing energy efficiency, and simplifying maintenance. This results in more consistent airflow and longer equipment life.Q: What are the primary benefits of using this centrifugal blower in commercial ventilation?

A: Users gain optimized air flow, low noise levels (below 78 dB), and long service life. Its compact dimensions and reliable operation under diverse temperature ranges make it an excellent choice for continuous ventilation needs in commercial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 300 MM X 100 MM

Price 4000 INR

Minimum Order Quantity : 5 Pieces

Weight : Approx. 18 Kg

Pressure : Other, Upto 65 mmWG

Output Power : 0.75 kW

Capacity : 8001200 CFM

SISW Centrifugal Blower 165 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Weight : 8 kg

Pressure : Other, 50 mm WG

Output Power : 0.37 kW

Capacity : 200 CFM

SISW Centrifugal Blower 610 MM X 250 MM

Price 16000 INR

Minimum Order Quantity : 5 Pieces

Weight : 48 Kg

Pressure : Other, 90 mm WC

Output Power : 3.7 kW

Capacity : 2800 CMH

SISW Centrifugal Blower 300 MM X 125 MM

Price 4500 INR

Minimum Order Quantity : 5 Pieces

Weight : Approx 20 kg

Pressure : Other, Up to 750 mm WG

Output Power : 0.75 kW

Capacity : 10001500 m/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS