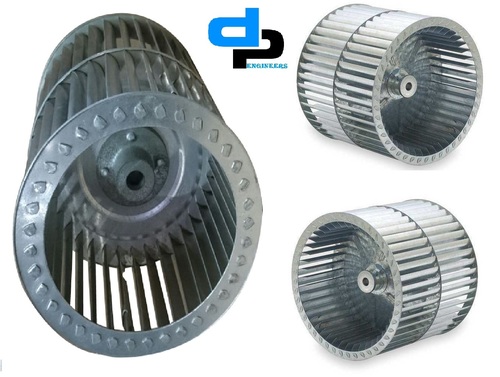

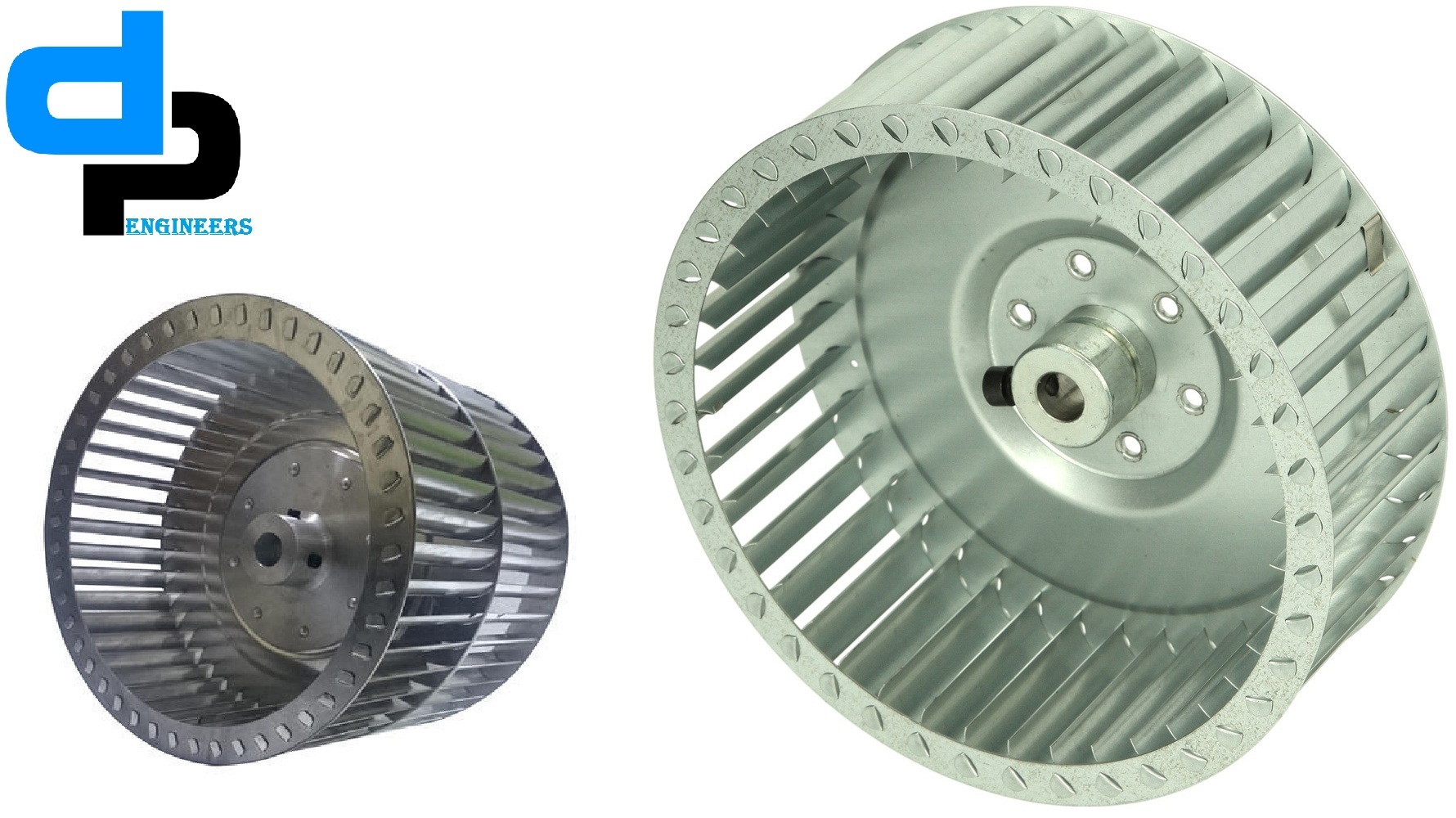

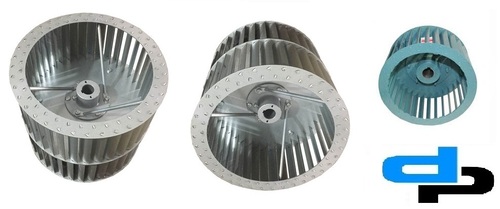

SISW Centrifugal Blower 150 MM X 63 MM

SISW Centrifugal Blower 150 MM X 63 MM Specification

- Max Pressure

- 150 mmWG

- Power

- 0.18-0.37 kW

- Output Power

- 0.25 HP

- Life Span

- Up to 7 years

- Motor Power

- 0.25 HP

- Flow Rate

- 250 to 350 m/hr

- Pressure Range

- Up to 150 mmWG

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 250-350 m/h

- Pressure

- High Pressure

- Application

- Ventilation, Industrial Air Handling, HVAC, Dust Collection

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- Approx. 8 kg

- Dimension (L*W*H)

- 150 mm x 63 mm

- Color

- Blue

SISW Centrifugal Blower 150 MM X 63 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Haryana, Delhi, Gujarat, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About SISW Centrifugal Blower 150 MM X 63 MM

SISW Centrifugal Blower 150 MM X 63 MM

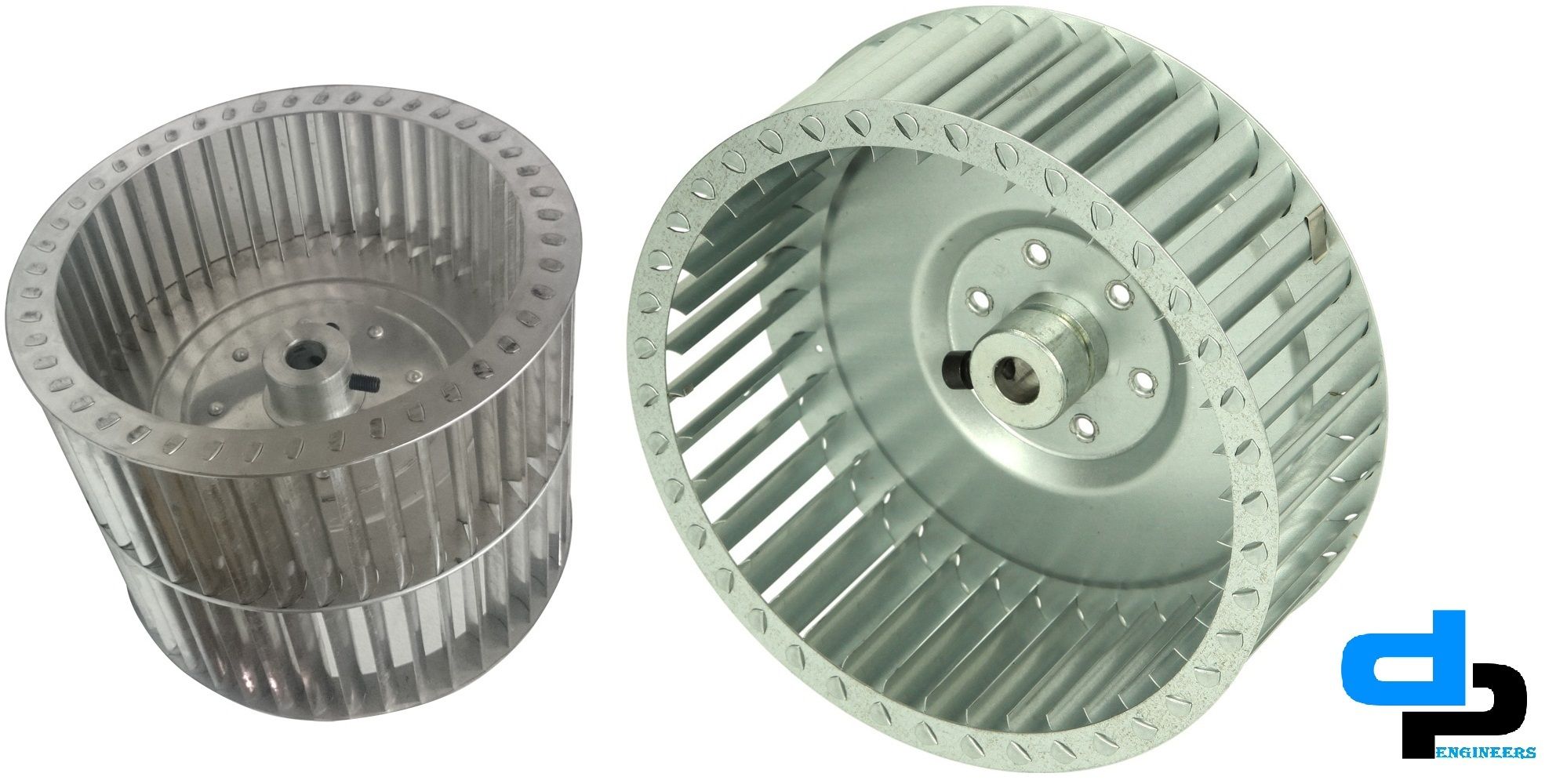

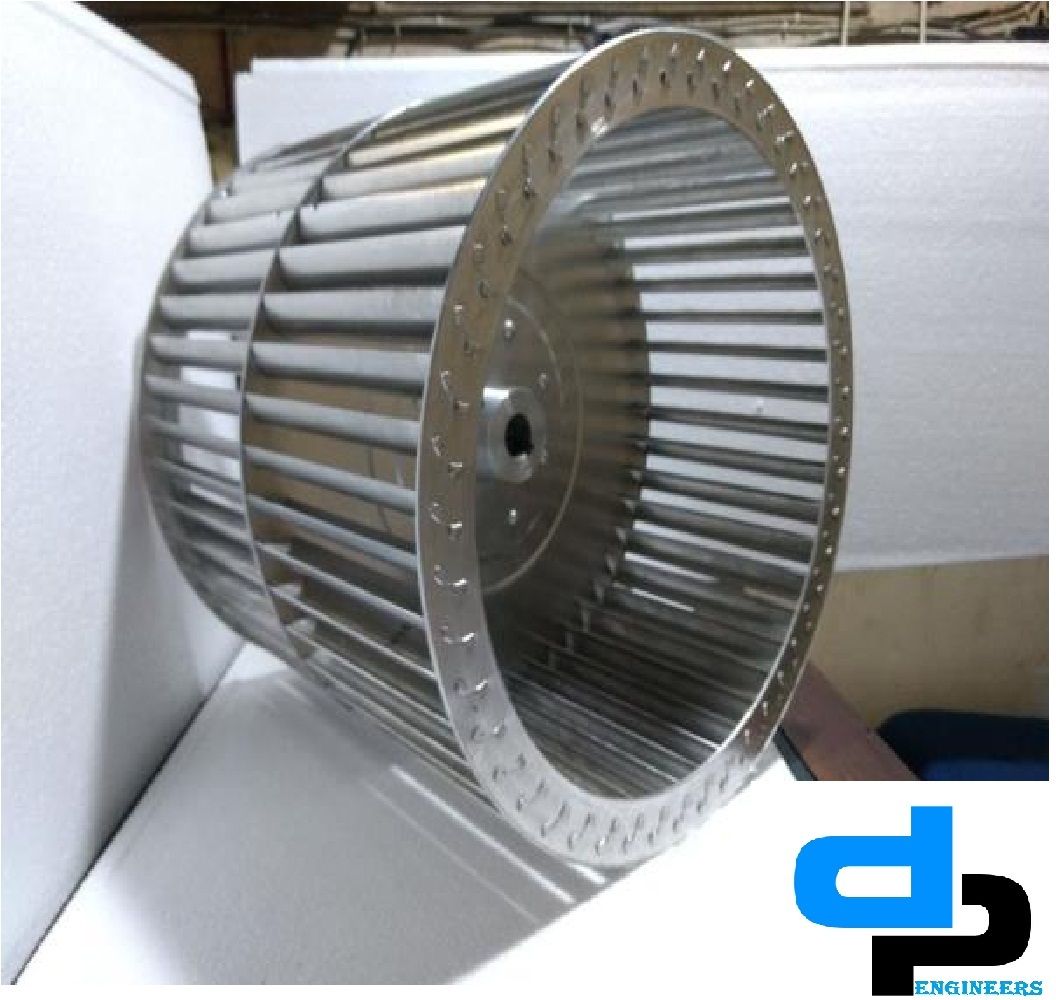

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCHES | |||

| 5 | DP 6 25 | 150 X 63 X 122 | 6 X 2.5 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Efficient Air Handling for Industrial Applications

Designed for demanding settings, the SISW Centrifugal Blower delivers optimal performance in ventilation, HVAC systems, and dust collection. Its high pressure and substantial airflow capacity ensures effective air movement, contributing to improved indoor air quality and operational reliability in manufacturing, commercial, and industrial environments.

Robust Construction for Longevity

Constructed from mild steel and featuring a totally enclosed fan-cooled (TEFC) motor, this blower resists wear and environmental stress. Its Class F insulation and ball bearing design extend operational life up to 7 years, offering low maintenance and high reliability even under continuous use.

FAQs of SISW Centrifugal Blower 150 MM X 63 MM:

Q: How can the SISW Centrifugal Blower be installed?

A: This blower is base mounted for straightforward installation on flat surfaces. Secure bolts through the base ensure stability, and connection to a 220-240 V single-phase electrical supply is required. Adherence to the specified dimensions (150 mm x 63 mm) helps fit seamlessly into existing systems.Q: What applications is the SISW Centrifugal Blower suitable for?

A: It is ideal for ventilation, industrial air handling, HVAC systems, and dust collection in factories, commercial buildings, and workshops, offering high airflow and pressure to maintain clean and safe environments.Q: When should maintenance be performed on this blower?

A: Routine maintenance is recommended every six months to check ball bearings, clean the impeller, and inspect insulation. Operating conditions may call for more frequent attention in dusty or high-utilization settings.Q: Where is the SISW Centrifugal Blower commonly used?

A: It is widely used across India by exporters, manufacturers, suppliers, and traders for industrial and commercial ventilation, air handling units, and dust collection solutions, especially where reliable, high-pressure airflow is required.Q: What benefit does the forward-curved impeller provide?

A: The forward-curved impeller ensures high pressure and stable airflow, making the blower well-suited for applications needing consistent air delivery and noise levels below 80 dB, aiding in worker comfort and equipment efficiency.Q: How does the blower handle different operating temperatures?

A: With an operating temperature range from -10C to +55C and Class F insulation, the blower maintains performance and safety across varying environmental conditions, ensuring suitability for diverse climates and industries.Q: What distinguishes the TEFC enclosure in this blower?

A: The Totally Enclosed Fan Cooled (TEFC) enclosure protects the motor from dust, moisture, and contaminants, promoting longer motor life, steady performance, and reduced downtime in dusty and harsh operational environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sisw Centrifugal Blower-Centrifugal Blower Category

SISW Centrifugal Blower 300 MM X 150 MM

Price 5000 INR

Minimum Order Quantity : 4 Pieces

Max Pressure : 150 mmWG

Color : Blue / Grey

Frequency (MHz) : 50 Hz

Motor Speed : 2800 RPM

SISW Centrifugal Blower 165 MM X 100 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Max Pressure : 60 mm WG

Color : Blue

Frequency (MHz) : 50 Hz

Motor Speed : 2800 RPM

SISW Centrifugal Blower 610 MM X 250 MM

Price 16000 INR

Minimum Order Quantity : 5 Pieces

Max Pressure : 120 mm WC

Color : Blue

Frequency (MHz) : 50 Hz

Motor Speed : 1440 RPM

SISW Centrifugal Blower 250 MM X 125 MM

Price 1800 INR

Minimum Order Quantity : 5 Pieces

Max Pressure : 80 mm WC

Color : Blue/Grey

Frequency (MHz) : 50 Hz

Motor Speed : 2880 RPM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS