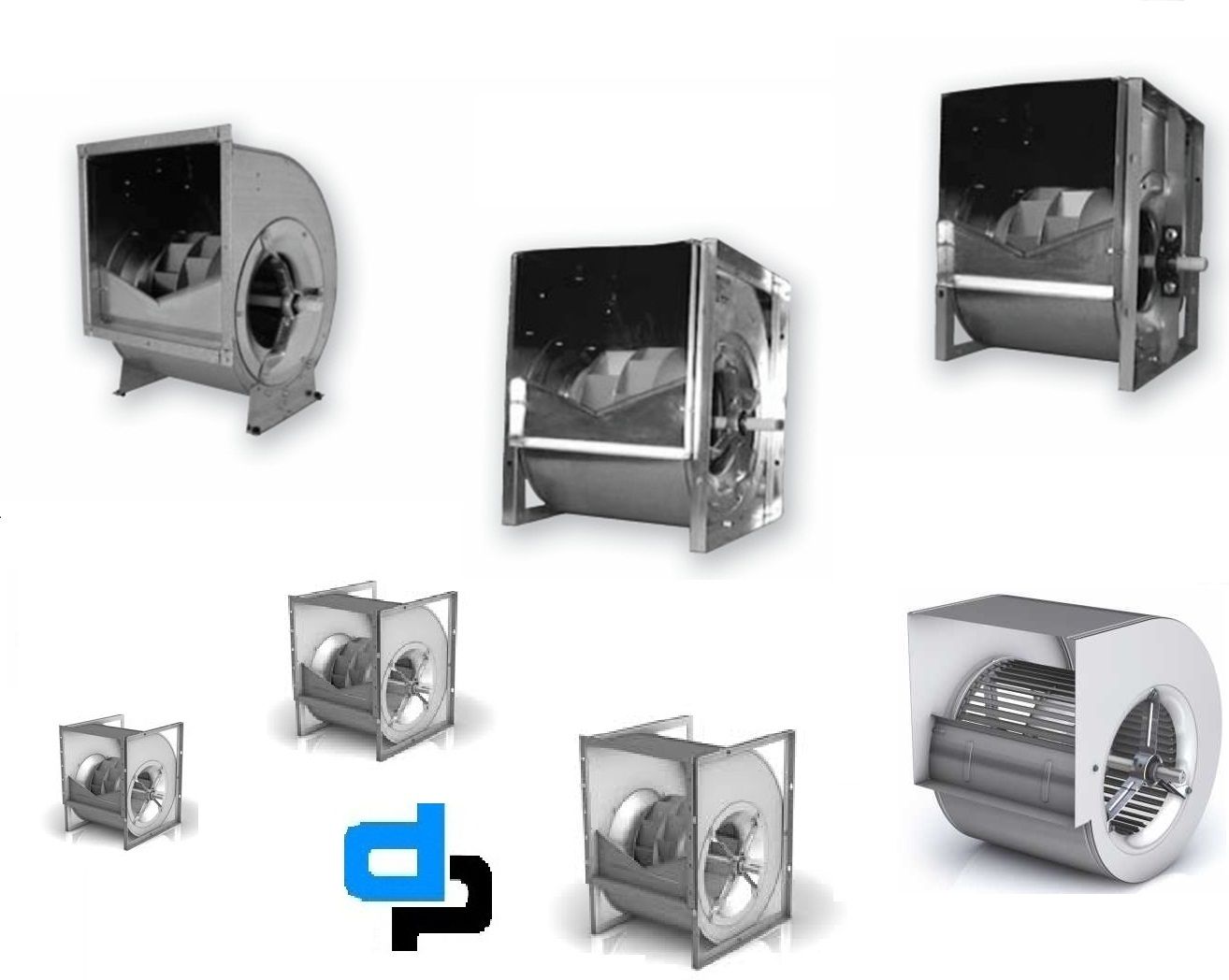

Nicotra Backward Curved Centrifugal Fan RDH 710 K

Nicotra Backward Curved Centrifugal Fan RDH 710 K Specification

- Pressure Range

- 600 - 1200 Pa

- Motor Power

- 7.5 kW

- Life Span

- More than 10 Years

- Flow Rate

- Up to 35,000 m/h

- Output Power

- 7.5 kW

- Power

- Up to 11 kW

- Max Pressure

- 1200 Pa

- Product Type

- Backward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 14000 to 35000 m/h

- Pressure

- Up to 1200 Pa

- Application

- Ventilation, HVAC System, Industrial Air Handling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1450 RPM

- Noise Level

- 84 dB(A)

- Power Source

- Electric

- Voltage

- 400 V

- Weight

- 175 kg

- Dimension (L*W*H)

- Approx. 990 x 950 x 900 mm

- Color

- Grey

Nicotra Backward Curved Centrifugal Fan RDH 710 K Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Delhi, Gujarat, North India, Kerala, Central India, Odisha, Chhattisgarh, Karnataka, All India

About Nicotra Backward Curved Centrifugal Fan RDH 710 K

Nicotra Backward Curved Centrifugal Fan RDH 710 K

| Product | RDH 710 K |

| Brand | Nicotra |

| Description | Extractor Fan |

| Condition | New |

Find Cheap Spare Parts For Machines Using The Products of Nicotra.Our Team of Experts Will Find the Best Sales Prices For Products of Nicotra - RDH 710 K Extractor Fan in USA.Using the Products of Nicotra Will Minimize Your Costs On Spare Parts.Our Job Is To Save You Time And Minimize Your Expenses On Spare Parts And Industrial Components.Our Company Is Not An Official Distributor of Nicotra, But We Are Selling Their Products At Competitive Prices.Purchase High Quality Spare Parts of Nicotra - RDH 710 K Extractor fan in INDIA on Cheap Prices.With Each Day We Gain More and More Experience and That's Why We Are Able to Satisfy Your Needs For Spare Parts.

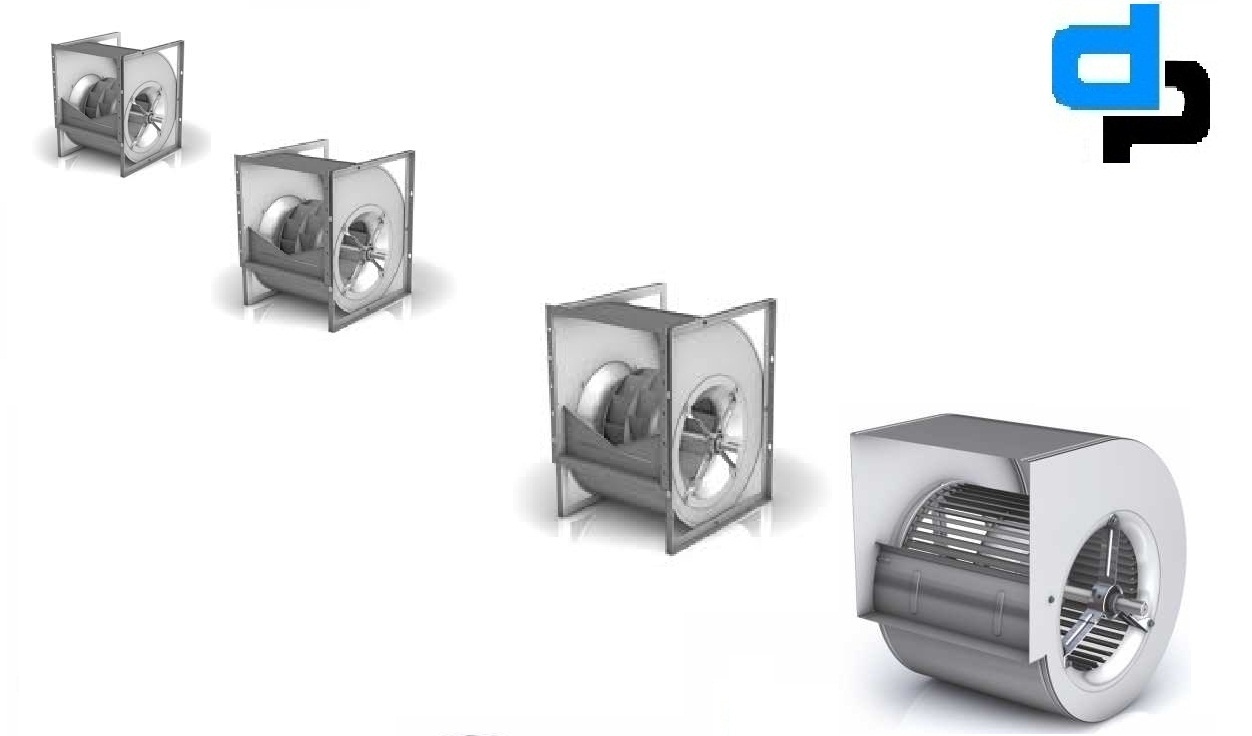

Designed for Industrial Excellence

The RDH 710 K brings optimal energy efficiency and robust performance to demanding ventilation and HVAC tasks. Its backward curved impeller, fabricated from reaction welded steel, ensures reliable operation even in tough environments. With versatile mounting options and a protective galvanized steel frame, it caters perfectly to industrial air handling requirements.

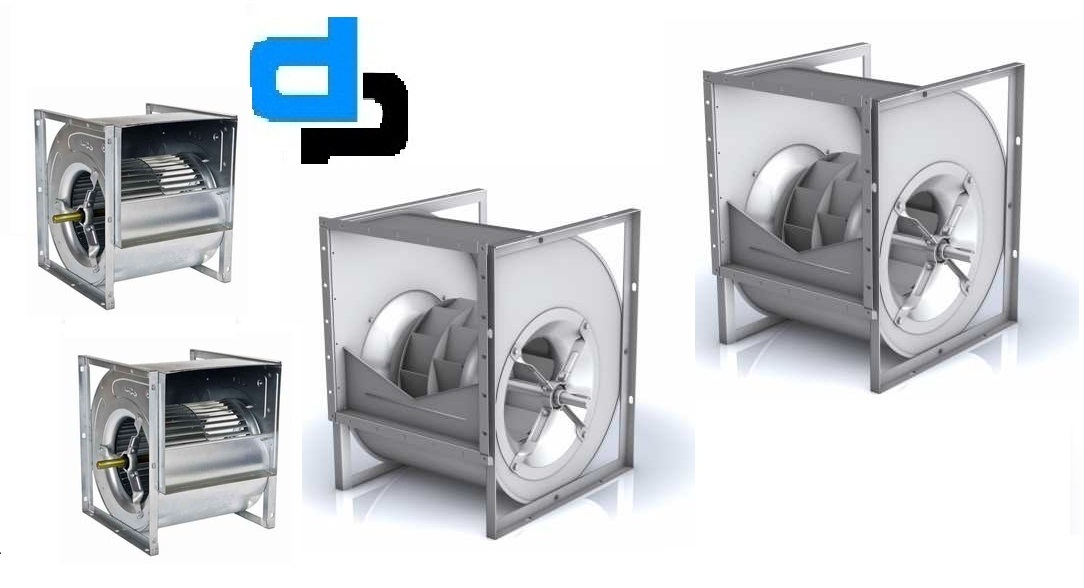

Premium Protection and Longevity

Engineered with an IP55 protection class and Class F insulation, this fan resists dust and moisture ingress while withstanding temperatures ranging from -20C to +60C. Its durable construction translates to a lifespan of over 10 years, reducing maintenance cycles and ensuring consistent performance in harsh industrial and commercial settings.

Efficient and Versatile Applications

With a powerful direct driven 7.5 kW motor and output capabilities up to 35,000 m/h, the RDH 710 K excels in large-volume ventilation and HVAC systems. Suitable for factories, warehouses, and industrial complexes, it provides quiet operation at 84 dB(A), meeting the diverse demands of modern air handling applications.

FAQs of Nicotra Backward Curved Centrifugal Fan RDH 710 K:

Q: How is the Nicotra RDH 710 K centrifugal fan typically installed in industrial applications?

A: The RDH 710 K can be frame or base mounted, providing flexibility for integration into various ventilation or HVAC setups. Its flange connection type ensures secure attachment, making the installation process straightforward and adaptable to site-specific requirements.Q: What key benefits does the backward curved impeller design offer?

A: The backward curved impeller made from dynamically balanced, reaction welded steel offers superior airflow efficiency, enhanced static pressure generation (up to 1200 Pa), and improved energy savings, making it ideal for demanding air handling and industrial extraction processes.Q: When should the RDH 710 K fan be considered for use in HVAC and ventilation systems?

A: It is recommended for scenarios requiring high air volumes (14,00035,000 m/h) and moderate to high-pressure demands (6001200 Pa), such as industrial air handling units, large commercial ventilations, and process cooling or extraction systems.Q: What measures ensure the durability and long service life of this fan?

A: The galvanised steel body, IP55 protection, Class F insulation, and a robust welded impeller help the fan endure harsh conditions, mechanical stresses, and moisture exposure, resulting in a reliable operational lifespan exceeding 10 years.Q: Where is the Nicotra RDH 710 K centrifugal fan most commonly utilized?

A: This fan is widely used in industrial facilities, commercial complexes, ventilation ducts, manufacturing plants, and large-scale HVAC systems across India and international markets, serving roles in air handling, ventilation, and process air movement.Q: What is the standard maintenance process for this centrifugal fan?

A: Routine maintenance involves periodic cleaning, checking dynamic balancing, and ensuring the motor and housing remain free from obstruction or excessive dust. Its robust design minimizes the need for frequent servicing under normal usage conditions.Q: How does the direct drive system affect the fans performance and reliability?

A: The direct drive setup reduces mechanical losses, eliminates the need for belt maintenance, and provides stable, efficient operation at 1450 RPM. This supports consistent performance while simplifying the upkeep process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series RDH Nicotra Backard Curved Centrifugal Fan- Category

Nicotra Backward Curved Centrifugal Fan RDH 180 R

Price 18000 INR

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 50 Hz

Voltage : 230 V AC

Application : Other, HVAC systems, Industrial ventilation, Building exhaust

Power Source : Other, Electric

Nicotra Backward Curved Centrifugal Fan RDH 225 R

Price 21800.00 INR

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 50 Hz

Voltage : 230/400 V

Application : Other, Ventilation, HVAC, Air Handling Units, Industrial Processes

Power Source : Other, Electric

Nicotra Backward Curved Centrifugal Fan RDH 560 R

Price 60000.00 INR

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 50 Hz

Voltage : 415 V

Application : Other, HVAC, Industrial Ventilation, Air Handling Units, General Exhaust

Power Source : Other, Electric

Nicotra Backward Curved Centrifugal Fan RDH 900 K

Price 175000.00 INR

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 50 Hz

Voltage : 380415 V

Application : Other, HVAC, Industrial Ventilation, Air Handling Units, Exhaust Systems

Power Source : Other, Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS