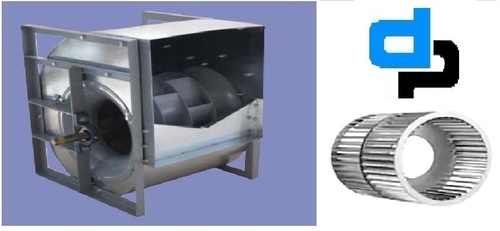

Nicotra Backward Curved Centrifugal Fan RDH 900 K

Nicotra Backward Curved Centrifugal Fan RDH 900 K Specification

- Max Pressure

- 1200 Pa

- Power

- 7.5 - 15 kW

- Life Span

- More than 10 years (with proper maintenance)

- Output Power

- 12.5 kW

- Motor Power

- 12.5 kW (typical)

- Flow Rate

- Up to 32,000 m³/h

- Pressure Range

- 500 - 1200 Pa

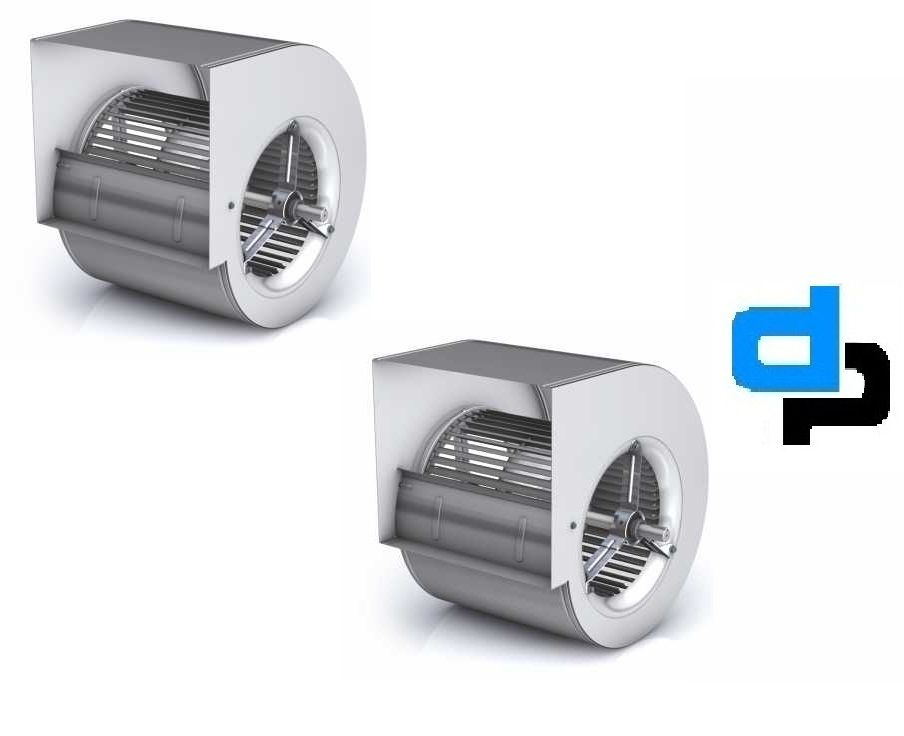

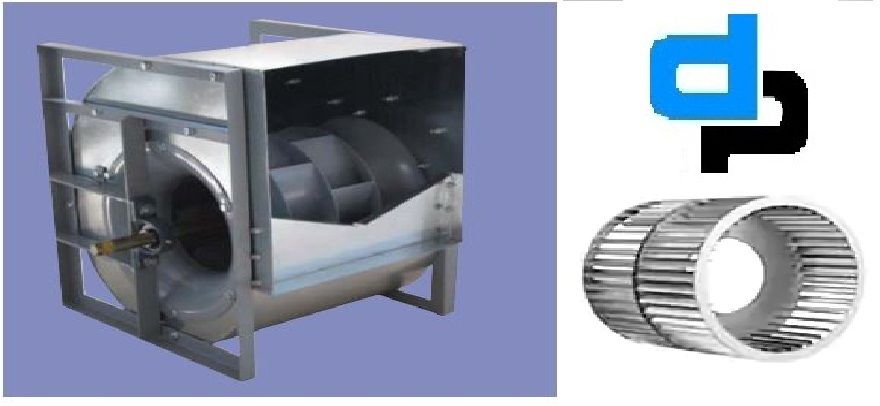

- Product Type

- Backward Curved Centrifugal Fan

- Material

- Powder Coated Mild Steel / Galvanized Steel

- Capacity

- 18000 - 32000 m³/h

- Pressure

- Up to 1200 Pa

- Application

- HVAC, Industrial Ventilation, Air Handling Units, Exhaust Systems

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1450 RPM

- Noise Level

- Below 85 dB(A)

- Power Source

- Electric

- Voltage

- 380-415 V

- Weight

- 310 kg

- Dimension (L*W*H)

- 1200 mm x 1150 mm x 910 mm (approx.)

- Color

- Grey / Metallic

Nicotra Backward Curved Centrifugal Fan RDH 900 K Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Uttarakhand, South India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Daman and Diu, Lakshadweep, North India, East India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

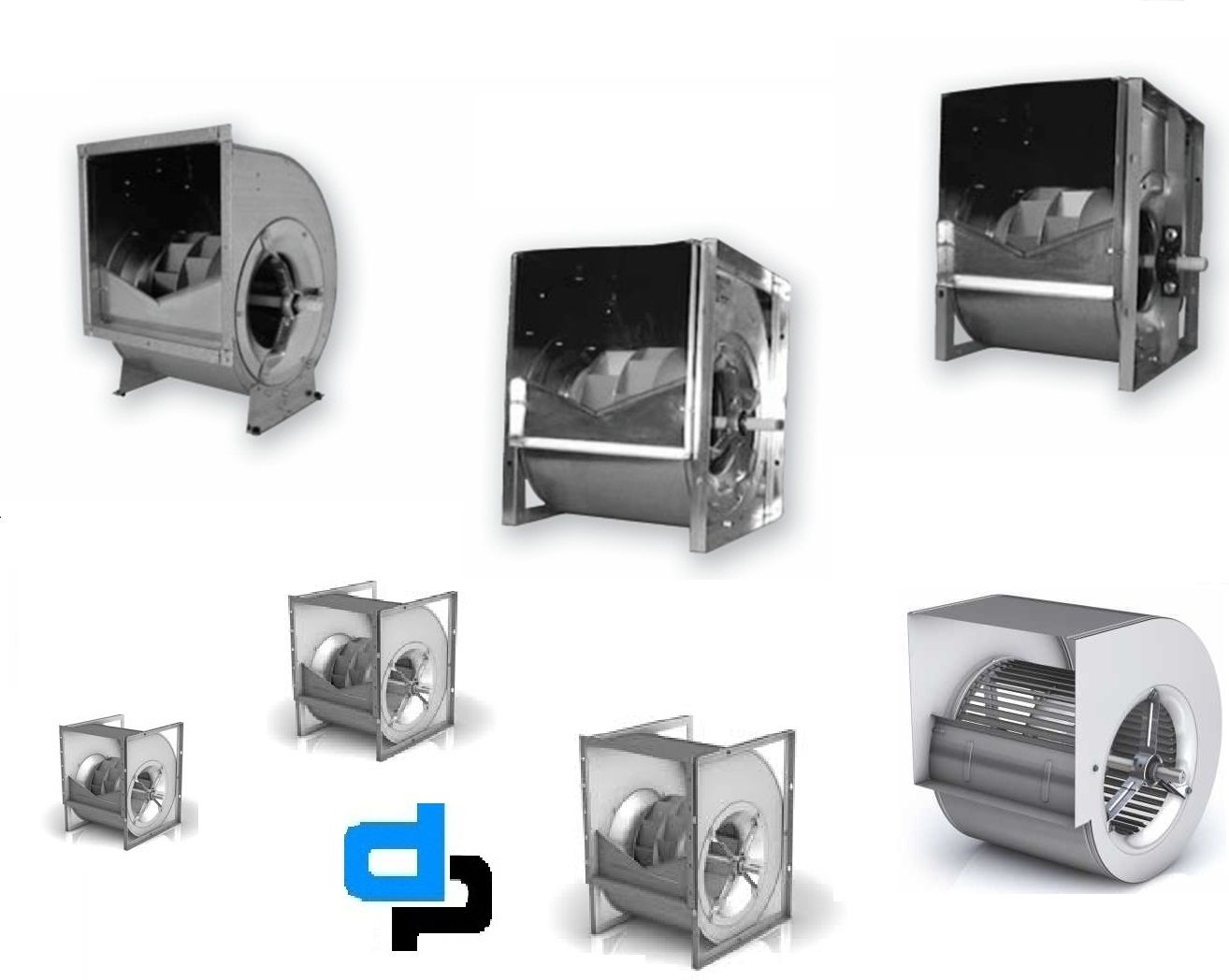

About Nicotra Backward Curved Centrifugal Fan RDH 900 K

Nicotra Backward Curved Centrifugal Fan RDH 900 K

| Product | RDH 900 K |

| Brand | Nicotra |

| Description | Extractor Fan |

| Condition | New |

Find Cheap Spare Parts For Machines Using The Products of Nicotra.Our Team of Experts Will Find the Best Sales Prices For Products of Nicotra - RDH 900 K Extractor Fan in USA.Using the Products of Nicotra Will Minimize Your Costs On Spare Parts.Our Job Is To Save You Time And Minimize Your Expenses On Spare Parts And Industrial Components.Our Company Is Not An Official Distributor of Nicotra, But We Are Selling Their Products At Competitive Prices.Purchase High Quality Spare Parts of Nicotra - RDH 900 K Extractor fan in INDIA on Cheap Prices.With Each Day We Gain More and More Experience and That's Why We Are Able to Satisfy Your Needs For Spare Parts.You May Fill Out Our Request Form or Send Your Enquiry

Engineered for Demanding Applications

The Nicotra RDH 900 K centrifugal fan is engineered to handle challenging industrial and commercial air movement tasks. Its backward curved impeller and welded construction assure longevity and resistance to wear, while its high airflow capacity and pressure range suit demanding ventilation and HVAC scenarios. With a solid floor-mount design and direct-coupled drive, the fan fits seamlessly into a variety of air handling environments.

Efficient and Low Maintenance Operation

Sealed-for-life, maintenance-free bearings mean routine lubrication is unnecessary, reducing downtime and operating costs. The motor sits outside the airstream for enhanced cooling and protection, supporting a long life span (over 10 years with periodic inspection). Class F insulation and IP55 protection further guarantee consistent operation and resilience against adverse conditions.

FAQs of Nicotra Backward Curved Centrifugal Fan RDH 900 K:

Q: How is the Nicotra RDH 900 K centrifugal fan installed and where is it typically used?

A: The RDH 900 K is floor-mounted and directly coupled for straightforward installation. Its commonly used in industrial ventilation systems, commercial HVAC setups, air handling units, and exhaust systems due to its high airflow and pressure capabilities.Q: What kind of maintenance does the RDH 900 K require and how often?

A: This fan is built with sealed-for-life, maintenance-free bearings, meaning frequent servicing is not needed. However, periodic inspection is recommended to ensure optimal performance and to extend the lifespan beyond 10 years.Q: What are the operational benefits of choosing a backward curved, welded impeller fan like the RDH 900 K?

A: The backward curved, welded impeller provides enhanced durability, higher efficiency, and lower noise levels, all while preventing accumulation of dust and debris. This results in reliable operation and reduced energy costs.Q: At what temperatures and environments can the RDH 900 K safely operate?

A: The fan is rated for use in ambient temperatures from -20C up to +55C, making it suitable for a broad range of environments from cold storage to industrial workshops.Q: How does the protection class (IP55) and insulation class (Class F) benefit the RDH 900 K?

A: IP55 protection shields the fans motor and components from dust and water jets, while Class F insulation allows the motor to withstand higher operating temperatures, ensuring safety and a longer service lifespan.Q: What is the typical power usage and flow capacity of this fan model?

A: This model typically operates with a motor power of around 12.5 kW, supports electrical input of 380-415V at 50 Hz, and delivers airflow rates up to 32,000 m/h, making it efficient for large-scale ventilation.Q: Why is the motor of the RDH 900 K positioned outside the air stream?

A: Placing the motor outside the airstream helps in keeping it cooler, preventing contamination from process air, and facilitating easier maintenance and inspection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series RDH Nicotra Backard Curved Centrifugal Fan- Category

Nicotra Backward Curved Centrifugal Fan RDH 500 R

Price 50000.00 INR

Minimum Order Quantity : 1 Piece

Pressure : Other, up to 1000 Pa

Product Type : Others, Backward Curved Centrifugal Fan

Life Span : Over 30,000 hrs

Capacity : up to 8000 m³/h

Nicotra Backward Curved Centrifugal Fan RDH 800 K

Price 140000.00 INR

Minimum Order Quantity : 1 Piece

Pressure : Other, up to 1200 Pa

Product Type : Others, Backward Curved Centrifugal Fan

Life Span : 10 Years

Capacity : up to 35000 m³/h

Nicotra Backward Curved Centrifugal Fan RDH 710 R

Price 98600.00 INR

Minimum Order Quantity : 1 Piece

Pressure : Other, 8001200 Pa

Product Type : Others, Backward Curved Centrifugal Fan

Life Span : 1015 Years (under normal operating conditions)

Capacity : up to 35000 m³/h

Nicotra Backward Curved Centrifugal Fan RDH 630 R

Price 76000.00 INR

Minimum Order Quantity : 1 Piece

Pressure : Other, max 1000 Pa

Product Type : Others, Backward Curved Centrifugal Fan

Life Span : More than 10 years

Capacity : up to 14000 m³/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS