Nicotra Backward Curved Centrifugal Fan RDH 280 R

Nicotra Backward Curved Centrifugal Fan RDH 280 R Specification

- Max Pressure

- 270 Pa

- Motor Power

- 0.37 kW

- Flow Rate

- Up to 1600 m/h

- Power

- 0.37 kW

- Output Power

- 0.37 kW

- Life Span

- Approx. 40,000 hours

- Pressure Range

- 0-270 Pa

- Product Type

- Backward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- Up to 1600 m/h

- Pressure

- 270 Pa

- Application

- HVAC, Industrial Ventilation, Air Handling Units, Clean Rooms

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <70 dB(A)

- Power Source

- Electric

- Voltage

- 230/400 V AC

- Weight

- Approx. 13 kg

- Dimension (L*W*H)

- Approx. 420 x 420 x 400 mm

- Color

- Silver Grey

Nicotra Backward Curved Centrifugal Fan RDH 280 R Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Lakshadweep, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Uttar Pradesh, Gujarat, Telangana, Jharkhand, Chhattisgarh, All India

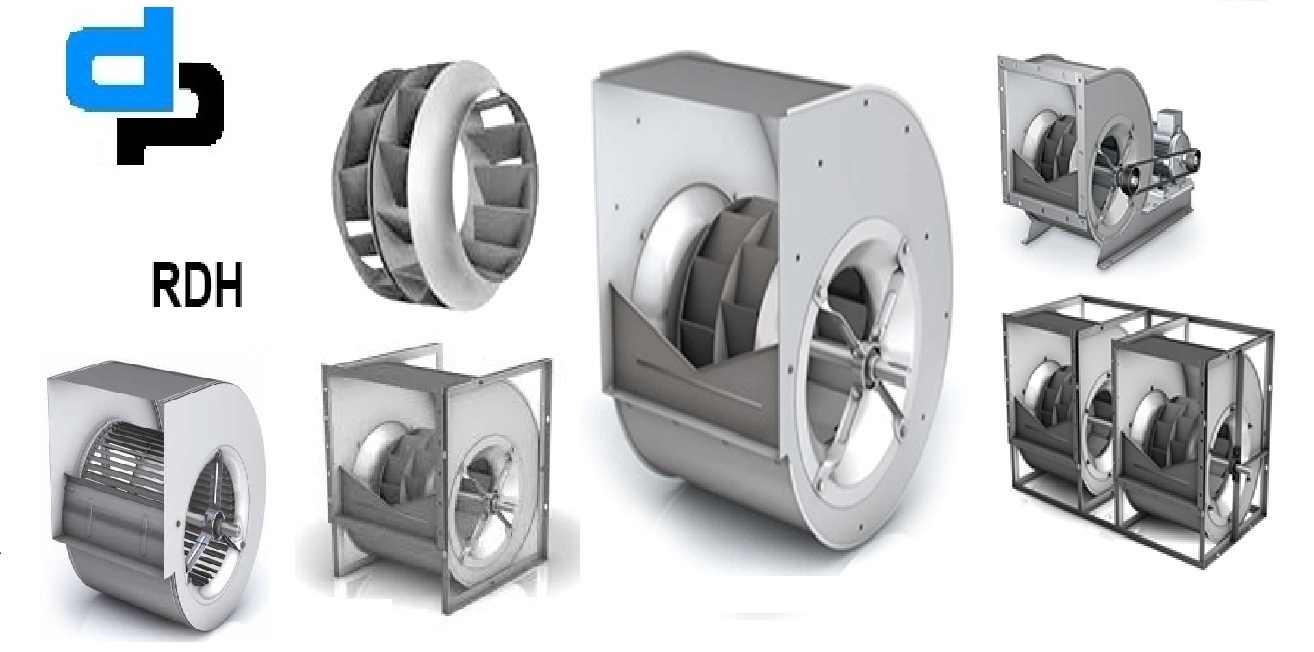

About Nicotra Backward Curved Centrifugal Fan RDH 280 R

Nicotra Backward Curved Centrifugal Fan RDH 280 R

| Product | RDH 280 R |

| Brand | Nicotra |

| Description | Extractor Fan |

| Condition | New |

Find Cheap Spare Parts For Machines Using The Products of Nicotra.Our Team of experts will find the best sales prices for products of Nicotra - RDH 280 R Extractor Fan in USA.Using the products of Nicotra will minimize your costs on spare parts.Our job is to save you time and Minimize your Expenses on spare Parts and industrial components.Our Company is Not an Official Distributor of Nicotra, but we are selling their Products at competitive prices.Purchase high quality spare parts of Nicotra - RDH 280 R Extractor fan in INDIA on cheap prices.With each day we gain more and more experience and that's why we are able to satisfy your needs for spare parts.

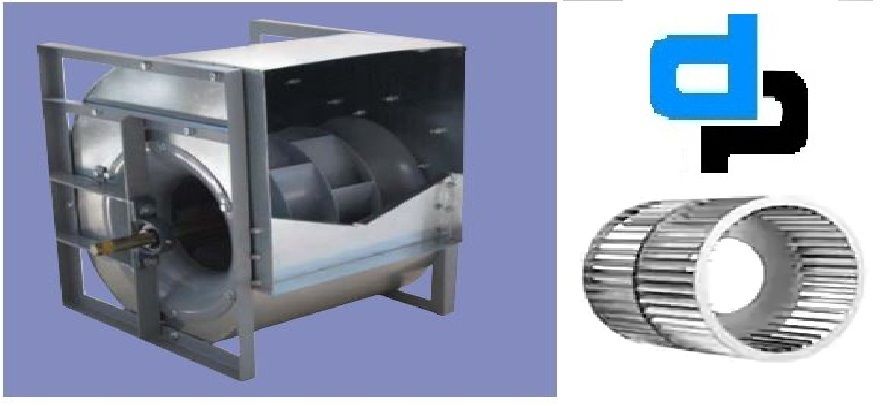

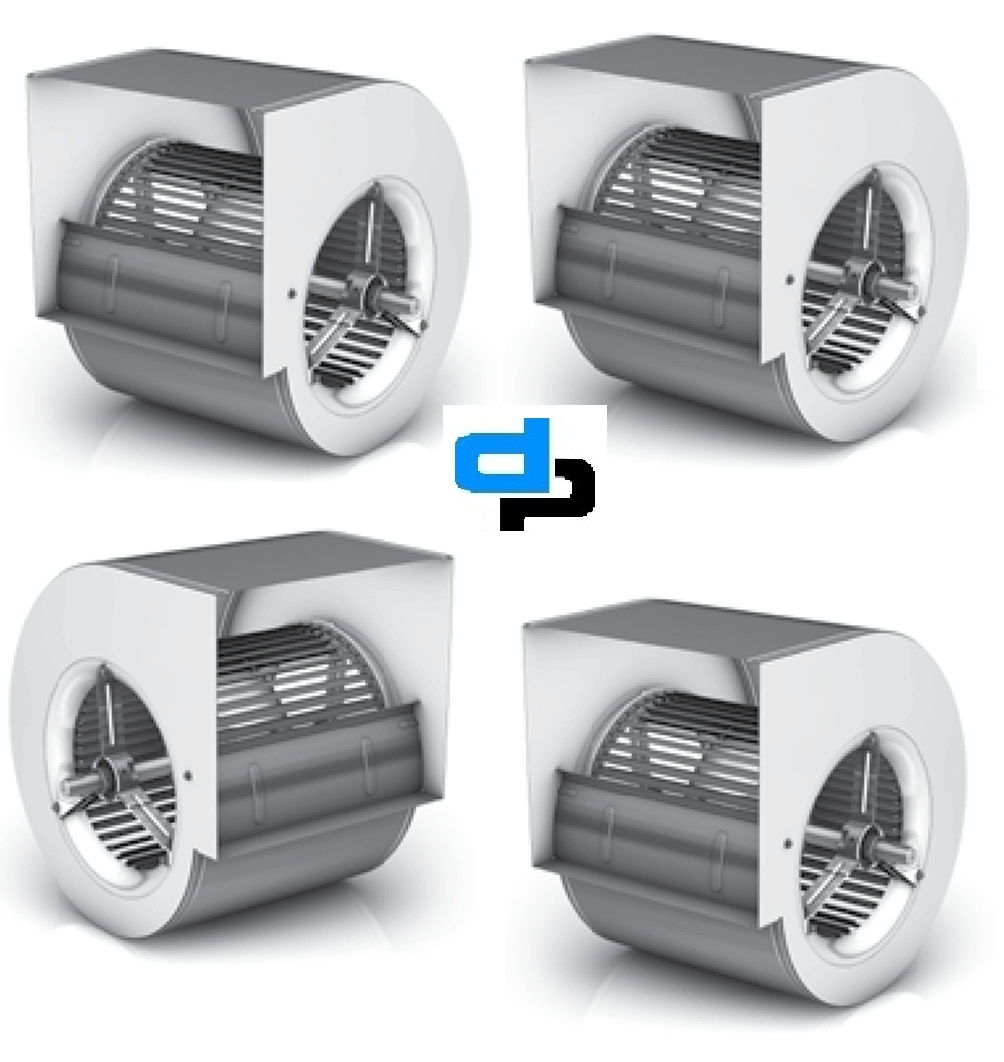

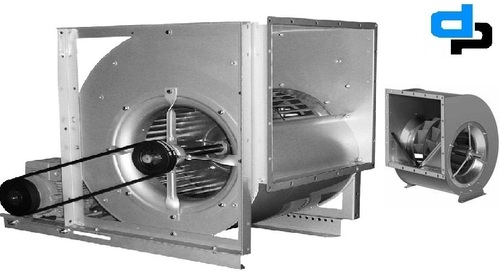

Built for Reliability and Durability

Constructed with heavy gauge steel housing and galvanized steel blades, the Nicotra RDH 280 R centrifugal fan offers superior strength and corrosion resistance. The sealed-for-life ball bearing extends the fans operational lifespan to approximately 40,000 hours even under rigorous working conditions, making it ideal for both industrial and commercial environments.

Versatile Application and Easy Integration

This fan is designed to support a wide spectrum of air movement requirements, including HVAC systems, air handling units, clean rooms, and industrial ventilation. Its base-mounted configuration and compatibility with single or three-phase power supplies make installation and electrical integration straightforward in diverse settings.

Efficient and Quiet Performance

Delivering a high flow rate up to 1600 m/h and a maximum pressure of 270 Pa, the RDH 280 R ensures effective ventilation while maintaining low noise levels under 70 dB(A). Its backward-curved impeller design guarantees energy-efficient operation, reducing operational costs without compromising airflow performance.

FAQs of Nicotra Backward Curved Centrifugal Fan RDH 280 R:

Q: How do I install the Nicotra RDH 280 R centrifugal fan for optimal performance?

A: Begin by securely mounting the fan on a level base using the provided base-mounting brackets. Ensure the electrical connections match the single or three-phase specifications (230/400 V AC, 50 Hz), adhering to local electrical safety standards. The fan is suitable for both ducted and open applications in HVAC or industrial setups.Q: What are the primary benefits of a backward curved impeller in this fan model?

A: A backward curved impeller enhances energy efficiency by minimizing air turbulence and offers higher pressure capabilities. This results in greater airflow (up to 1600 m/h) at lower noise levels and improved reliability, making the fan ideal for demanding ventilation requirements.Q: When should I consider replacing or servicing the fans bearings?

A: The RDH 280 R uses sealed-for-life ball bearings, which are maintenance-free throughout the fans typical lifespan of about 40,000 hours. No regular bearing servicing is needed; replacement is only advised if operational noise increases or if the fan shows visible signs of wear.Q: Where can this centrifugal fan be used most effectively?

A: The fan is designed for use in HVAC systems, air handling units, clean rooms, and a variety of industrial ventilation applications. Its robust construction and IP54 protection allow it to operate reliably in challenging environments exposed to dust, humidity, and variable temperatures.Q: What is the process for adjusting the fan for different airflow requirements?

A: This fan operates at a fixed speed of 2800 RPM; however, adjusting system dampers or implementing variable frequency drives (if compatible with your setup) can help tailor the airflow to specific needs. Always consult the installation manual or a qualified technician for safe and proper adjustments.Q: What usage precautions should I observe to maximize lifespan and safety?

A: Ensure the fan is operated within the specified ambient temperature range (-20C to +60C) and only with compatible electrical supplies. Keep the impeller and housing clear of debris, and regularly inspect for any abnormal vibrations or noise. Proper installation and adherence to manufacturer guidelines help ensure safe and reliable use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series RDH Nicotra Backard Curved Centrifugal Fan- Category

Nicotra Backward Curved Centrifugal Fan RDH 225 R

Price 21800.00 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Voltage : 230/400 V

Product Type : Others, Backward Curved Centrifugal Fan

Application : Other, Ventilation, HVAC, Air Handling Units, Industrial Processes

Nicotra Backward Curved Centrifugal Fan RDH 180 R

Price 18000 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Voltage : 230 V AC

Product Type : Others, Backward Curved Centrifugal Fan

Application : Other, HVAC systems, Industrial ventilation, Building exhaust

Nicotra Backward Curved Centrifugal Fan RDH 1120 X1

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Voltage : 415 V

Product Type : Others, Backward Curved Centrifugal Fan

Application : Other, HVAC, Industrial Ventilation, Clean Rooms, Air Handling Units

Nicotra Backward Curved Centrifugal Fan RDH 1400 X1

Price 6500 INR / Piece

Minimum Order Quantity : 10 Pieces

Power Source : Electric Blower

Voltage : 210/415 Volt(v)

Product Type : Others, Exhaust Air Blower

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free