Kimo Make Differential Pressure Transmitter

Kimo Make Differential Pressure Transmitter Specification

- Display

- Digital Backlit LCD display

- Seal Material

- EPDM Seals

- Thread

- 1/8 NPT Female Connections

- Sensor Type

- Differential Pressure Sensor

- Outer Size

- Width 80 mm x Height 125 mm x Depth 55 mm

- Bourdon Tube

- Not Applicable (Electronic Sensing)

- Grade

- Industrial

- Material

- Polycarbonate Housing

- Processing Type

- Microprocessor Based

- Mount Type

- Wall mounting

- Scale Range

- 0 to 1000 Pa (customizable upon request)

- Accuracy

- 0.5% of Full Scale

- Finishing

- Textured Polycarbonate Housing

- Measure Pressure Of

- Air and non-corrosive gases

- Accessories

- Mounting brackets, installation manual

Kimo Make Differential Pressure Transmitter Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Kimo Make Differential Pressure Transmitter

Kimo Make Differential Pressure TransmitterProduct Description:

Measuring ranges

CP 111 : from -100 to +100 Pa with EV

CP 112 : from -1000 to +1000 Pa

CP 113 : from -10 000 to +10 000 Pa

CP 114 : from -500 to +500 mbar

CP 115 : from -2000 to +2000 mbar

Technical data

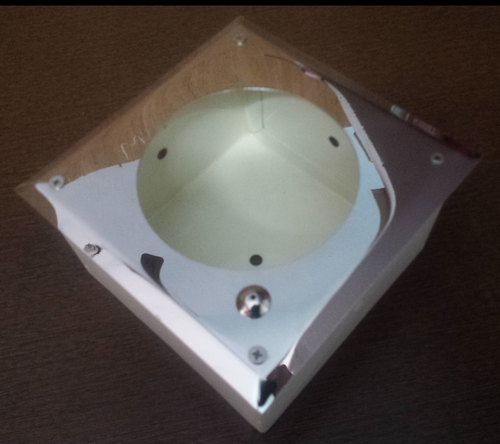

ABS housing - IP 65

With or without 10-digits LCD display

0-10 V or 4-20 mA output

Housing with simplified mounting system

Software or DIP switch configuration

Quick and easy mounting with the 1/4 turn system with wall-mount plate

Advanced Pressure Sensing Technology

Leverage accurate differential pressure measurement with electronic sensing technology, eliminating mechanical parts for greater reliability and easier maintenance. The built-in microprocessor delivers stable performance and swift response times under demanding industrial conditions.

Easy Installation and Adjustment

This transmitter comes with user-friendly mounting brackets and a removable terminal block for straightforward wall installation. Zero and span adjustments can be performed directly on the device using its integrated push buttons, simplifying calibration and configuration.

Robust Construction for Industrial Use

With an IP65-rated polycarbonate housing and EPDM seals, the transmitter withstands exposure to dust, moisture, and physical impacts. Its compact and robust design ensures longevity and durability in both indoor and outdoor applications.

FAQs of Kimo Make Differential Pressure Transmitter:

Q: How do I select the output signal for the Kimo Differential Pressure Transmitter?

A: You can easily choose between a 4-20 mA or 0-10 V DC output signal using the selectable settings available on the device. This flexibility allows integration into various industrial control systems.Q: What types of media can be measured with this pressure transmitter?

A: The transmitter is specifically designed for air and non-corrosive gas applications. It is not suitable for corrosive gases or liquids due to the sensors EPDM seals and electronic sensing mechanism.Q: Where is the best place to mount the transmitter for optimal performance?

A: For accurate measurement and easy access, the device should be wall-mounted using the included brackets. Ensure the area allows stable connection to 24V AC/DC power and that environmental conditions are within the recommended temperature range (0C to +50C).Q: How does the zero/span adjustment function work on the transmitter?

A: Zero and span adjustments are performed directly on the device via dedicated push buttons. This enables quick calibration, ensuring precise readings tailored to your specific pressure requirements.Q: What are the benefits of the digital backlit LCD display?

A: The digital backlit LCD ensures clear visibility of pressure readings in low-light industrial environments. It provides real-time data, simplifying monitoring and operation for technicians.Q: What maintenance process is required for this transmitter?

A: With its electronic sensing and robust polycarbonate housing, routine maintenance is minimal. Periodically check for dust buildup on the device and inspect connections; calibration can be easily managed using the onboard push buttons.Q: When should the transmitter be used over mechanical pressure gauges?

A: Use this transmitter when high measurement accuracy, fast response times, easy output signal integration, and electronic calibration are needed. It excels in environments that require IP65 ingress protection and microprocessor-based precision.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TOP Dwyer Magnehelic Gauge Wholesale Suppliers India Category

Magnehelic Gauge SS Plate Front Cover

Material : Other, Stainless Steel (Front Cover)

Sensor Type : Differential Pressure

Grade : SS304

Measure Pressure Of : Other, Air, Noncorrosive gases

Finishing : Other, Matte Brushed

Display : Analog

GI Magnehelic Gauge Box

Material : Stainless Steel

Sensor Type : Diaphragm sensor

Grade : Industrial

Measure Pressure Of : Other, Air & Noncorrosive gases

Finishing : Other, Polished stainless steel box

Display : Analog

KIMO Pressure Transmitter CP 100

Material : Other, Polycarbonate, ABS

Sensor Type : Capacitive Pressure Sensor

Grade : Industrial

Measure Pressure Of : Other, Air and Neutral Gases

Finishing : Other, Polycarbonate Housing with ABS Panel

Display : LCD Digital Display

Magnehelic Gauge SS BOX

Material : Other, Stainless Steel housing

Sensor Type : Differential pressure sensor

Grade : Industrialgrade

Measure Pressure Of : Low differential pressure in HVAC systems, Other

Finishing : Other, Stainless Steel Box

Display : Analog

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS