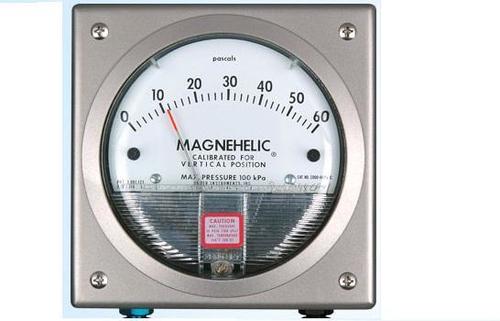

Magnehelic Gauge SS Plate Front Cover

Magnehelic Gauge SS Plate Front Cover Specification

- Grade

- SS304

- Display

- Analog

- Sensor Type

- Differential Pressure

- Bourdon Tube

- Absent

- Outer Size

- 110 mm (Diameter)

- Seal Material

- Neoprene

- Thread

- 1/8 NPT

- Material

- Stainless Steel (Front Cover)

- Dial Material

- Aluminum

- Pointer Material

- Stainless Steel

- Processing Type

- CNC Machined

- Diameter

- 110 mm

- Glass Size

- 90 mm

- Mount Type

- Panel Mount

- Scale Range

- 0-60 psi

- Accuracy

- 2% of Full Scale

- Finishing

- Matte Brushed

- Measure Pressure Of

- Air, Non-corrosive gases

- Accessories

- Mounting Screws, Gasket

Magnehelic Gauge SS Plate Front Cover Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Kerala, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About Magnehelic Gauge SS Plate Front Cover

Magnehelic Gauge SS Plate Front Cover

We are here to offer Magnehelic Gauge SS Plate Front Cover. It is designed to calibrate a broad spectrum of instruments from moving coil meters to process control systems and retain its precision over long periods in wide environmental conditions. These are customized as per as needs of clients.

Specifications:

Metal of construction S.S. 304

- Dial size: 4"

- Ranges: mm/wc,In/wc, Pascal

- Enclosure type: consul type & wall mounting

- Front panel: zero calibration gas selector switch optional

- 0-10,

- 0-25,

- 0-40,

- 0-50,

- 0-100 MM Wc , And

- 0- 60 pA,

- 0-250 pA.

- Used for high accuracy-guaranteed within 2% of full scale and for the wide choice of 81 models available to suit your needs precisely

Precision-Engineered for Gauge Longevity

This front cover is manufactured using high-grade SS304 and is processed through CNC machining. It ensures optimal durability, corrosion resistance, and a reliable fit for round differential pressure gauges with 110 mm diameter. The passivated, brushed finish delivers both aesthetic appeal and functional resilience in demanding environments.

Versatile Application in Sensitive Environments

Ideal for safeguarding pressure measurement devices in clean rooms, HVAC panels, and dust detection systems, this cover is particularly suited for areas where contamination and mechanical damage pose risks. Its compatibility with Dwyer Magnehelic gauges ensures flexibility for a wide range of industrial and laboratory settings.

Easy Installation & Secure Protection

The removable, panel-mountable design allows straightforward installation and maintenance. Included mounting screws and a neoprene gasket facilitate a secure, sealed fit, minimizing manual effort during setup. The protective plate helps preserve gauge accuracy and extends service life by shielding exposed surfaces from dust and impact.

FAQs of Magnehelic Gauge SS Plate Front Cover:

Q: How does the SS plate front cover benefit my Magnehelic gauge in an HVAC application?

A: The front cover offers durable protection against impacts, contamination, and dust. Its corrosion-resistant SS304 construction prolongs gauge accuracy and lifespan, crucial for maintaining reliable readings in HVAC systems.Q: What is the installation process for this removable front cover?

A: Installation is simplemount the cover on the gauge panel using the supplied screws and neoprene gasket for a snug, sealed fit. The design allows easy removal for maintenance or inspection without specialized tools.Q: When should I use a stainless steel front cover for my differential pressure gauge?

A: Use this cover whenever the gauge is exposed to harsh conditions, such as in dusty or humidity-sensitive environments like clean rooms or HVAC panels, to prevent calibration drift and damage.Q: Where can this front cover be installed?

A: It is designed for any panel-mount gauge setup compatible with Dwyer Magnehelic and similar models, commonly found in industrial, laboratory, and HVAC infrastructure.Q: What materials make up the front cover and its accessories?

A: The main cover is made from SS304 stainless steel with a matte brushed finish. It includes a neoprene seal gasket, aluminum dial, and stainless steel pointer, ensuring overall corrosion resistance and robust assembly.Q: How does the surface treatment contribute to durability?

A: Brushed and passivated finishes on the SS304 steel prevent corrosion, resist surface scratches, and maintain the metallic silver sheen, making it suitable for frequent handling and exposure to contaminants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in TOP Dwyer Magnehelic Gauge Wholesale Suppliers India Category

Sensocon Make Magnehelic Differential Pressure Gages -50 To 50 MMWC

Sensor Type : Diaphragm Sensing Element

Measure Pressure Of : Other, Air & NonCorrosive Gases

Scale Range : 50 to +50 mmWC

Accessories : Mounting Screws, Two Static Pressure Connectors

Display : Analog Dial

Grade : Industrial Grade

MS Box Flesh type Magnehelic Gauge

Sensor Type : Diaphragm sensor

Measure Pressure Of : Other, Air or noncorrosive gases

Scale Range : 060 Pascal

Accessories : None

Display : Mechanical dialtype display

Grade : Industrial grade

KIMO Temperature Transmitter

Sensor Type : PT100 Platinum Resistance

Measure Pressure Of : Other, Temperature Only

Scale Range : 50C to +100C

Accessories : Mounting Screws, User Manual

Display : Digital LED

Grade : Industrial

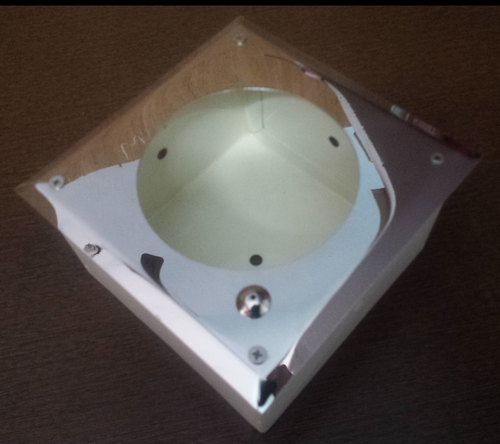

Mounting Box For Magnehelic Gauges

Sensor Type : Not applicable (analog display)

Measure Pressure Of : Other, Air or noncorrosive gases

Scale Range : Ranges vary as per Magnehelic specifications

Accessories : Mounting Box

Display : Analog

Grade : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS