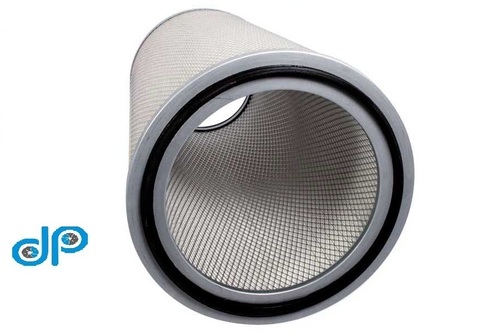

Heavy Duty Air Filter

Heavy Duty Air Filter Specification

- Capacity

- High Dust Holding Capacity (up to 10kg dust)

- Filter Type

- Cartridge / Panel Type

- Flow Rate

- High Flow (customized, up to 3500 m/h)

- Connecting Type

- Clamp / Flange Type

- Media Type

- Synthetic Non-woven / Pleated

- Filtration Grade

- Industrial Grade

- Pressure

- Up to 2.5 Bar

- Efficiency (%)

- 99%

- Temperature Range

- -20C to +80C

- Cleaning Method

- Washable, Replaceable

- Condition

- New

- Material

- Galvanized Steel Frame, Synthetic Filter Media

- Mesh

- Fine Mesh

- Diameter

- Custom Size / Multiple Options

- Construction

- Heavy Duty, Rugged Metal Frame

- Medium Filter

- Air

- Weight

- Depends on Size (approx. 1.5 - 4 kg)

- Shape

- Cylindrical

- Feature

- High Dirt-Holding Capacity, Long Service Life, Easy Installation, Robust Construction

Heavy Duty Air Filter Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Heavy Duty Air Filter

Heavy Duty Air FilterSpecifications:

Filter Material: Yellow Wood pulp

Caps Material: Anodized plate/Galvanized plate

Inner Frame: Galvanized punched-plate/Stainless Steel punched-plate

Built for Extreme Conditions

Designed to withstand harsh industrial environments, this heavy duty air filter excels in high-humidity conditions and is built with corrosion-resistant materials. The galvanized steel frame and anti-rust coating ensure long-lasting durability, even when exposed to up to 100% humidity and various contaminants.

Superior Filtration and Efficiency

With a filtration efficiency of 99% and a filtration surface area of up to 25 sq.ft., this air filter effectively captures fine particles, supporting high air flow rates while maintaining minimal pressure drop. Its suitable for both cartridge and panel filter systems, accommodating a broad range of industrial applications.

Reliable and Easy to Maintain

Thanks to its washable and replaceable synthetic filter media, maintenance is straightforward and cost-effective. The filters design supports quick installation using clamp or flange connections, and its high dust holding capacity means fewer change-outs, prolonging service intervals up to 12,000 hours depending on conditions.

FAQs of Heavy Duty Air Filter:

Q: How is the Heavy Duty Air Filter installed in industrial systems?

A: The air filter features versatile mounting options, allowing for both horizontal and vertical installation. It can be connected using clamp or flange types, enabling quick integration into HVAC systems, compressors, engines, or custom industrial setups.Q: What filtration efficiency does this air filter provide in industrial applications?

A: This heavy duty filter offers an industry-leading filtration efficiency of 99%, ensuring the effective removal of fine airborne contaminants and prolonged protection for equipment and personnel.Q: When should the air filter be cleaned or replaced for optimal performance?

A: Service intervals depend on environmental conditions and dust load, but with its washable media and high dust holding capacity (up to 10kg), cleaning or replacement is typically required after up to 12,000 hours of operation or when pressure drop increases significantly.Q: Where can this heavy duty air filter be used effectively?

A: It is ideal for use in industrial air filtration, HVAC systems, compressors, and engine air intake systems, providing effective air purification in manufacturing, processing plants, and other heavy-duty environments.Q: What benefits does the anti-rust and corrosion-resistant construction offer?

A: The anti-rust coating and corrosion-resistant materials increase service life, reduce maintenance needs, and ensure reliable operation in humid and chemically aggressive environments.Q: How does the robust construction impact filter durability and service life?

A: The galvanized steel frame and rugged metal design provide mechanical strength, allowing the filter to withstand high pressure (up to 2.5 Bar) and heavy-duty use. This contributes to the filters long lifespan, even in demanding industrial contexts.Q: What is the process for cleaning and maintaining the filter media?

A: The synthetic non-woven and pleated media are designed to be both washable and replaceable. Cleaning can be done using water or air under moderate pressure, helping restore performance and extend overall service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Anti Static Cartridge Filter

Media Type : Other, Anti Static Polyester Filter Media

Medium Filter : Other, Synthetic Fiber

Filter Type : Cartridge Filter

Connecting Type : Other, Flange Mounted

Condition : New

Mesh : Pleated Media

CYLINDRICAL FILTER CARTRIDGE

Media Type : Other, Perforated Sheet, Wire Mesh

Medium Filter : Other, Liquid, Air, Gas

Filter Type : Cartridge Filter

Connecting Type : Other, Threaded End, Flanged End

Condition : New

Mesh : Various Mesh Sizes Available

Hydraulic Filter for 1800 Concrete Pump

Media Type : Other, Microglass/synthetic filter media

Medium Filter : Other, Hydraulic oil

Filter Type : Return line filter

Connecting Type : Other, Threaded or flanged end connection

Condition : New

Mesh : Fine filtration mesh (customizable based on requirements)

Stainless Steel Mesh Filter Basket

Media Type : Other, Stainless steel mesh

Medium Filter : Other, Liquids, Gases, Oils or Chemicals

Filter Type : Mesh Basket Filter

Connecting Type : Other, Open top, Slipin or Custom fittings available

Condition : New

Mesh : Fine mesh (typically 60200 micron, customizable)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS