Filter Catriges

Filter Catriges Specification

- Flow Rate

- 10-50 LPM (depending on size, media and pressure)

- Filtration Grade

- Micron filtration (1-100 micron options)

- Cleaning Method

- Replaceable, Disposable

- Temperature Range

- 5C to 80C

- Efficiency (%)

- Up to 99.99%

- Capacity

- Depends on contaminant load and flow rate

- Connecting Type

- DOE or SOE (Double/Single Open End)

- Media Type

- Polypropylene, Cellulose, Glass Fiber

- Pressure

- Max 7 bar

- Filter Type

- Cartridge Filter

- Condition

- New

- Material

- Polypropylene, Stainless Steel, Glass Fiber, Polyester

- Mesh

- 1-100 micron (as per requirement)

- Diameter

- 2.5 inch, 4 inch (customizable)

- Construction

- Spun, Pleated, Wound, Melt Blown

- Medium Filter

- Liquid/Water, Oil, Chemical

- Weight

- Varies as per length and construction (typically 300-1500g)

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, chemical resistance, long service life

About Filter Catriges

Filter Catriges

Combination of pleated high-efficiency filtration media and an inner support core that forms a one-piece element that fits directly into your existing bag house tube sheet. Our Pulse Pleat replaces traditional filter bags and cages.

Pulse Pleat elements are the original pleated technology and are designed and manufactured to operate in the harshest of industrial environments more than three million Pulse Pleat pleated filters have been sold for industrial air filtration systems.

Pulse Pleat Advantages- Requires less compressed air pressure to pulse clean

- Operates across a wide range of temperatures and applications Increases filtration area 2-3 times

- Dramatically reduces air-to-cloth ratios

- Reduces operating pressure differential

- Reduces collection operational energy costs

- Direct replacement for bags and cages

- Substantially reduces installation time

- Shorter length keeps the elements out of the inlet gas stream, reducing abrasion

- Significantly more efficient than standard felt media

Customizable Filtration for Every Industry

Whether for water purification, chemical processing, or food production, our cartridges offer length and micron choices to match any filtration requirement. Robust construction and varied seal materials ensure seamless integration into new or existing systems. Choose from polypropylene, stainless steel, glass fiber, or polyester media and inner cores to guarantee durability and compatibility for diverse operating conditions.

Optimized Performance and Safety

With smooth or grooved finishes and several FDA-grade options available, these cartridges deliver superior contaminant removal, high flow rates (1050 LPM), and reliable pressure containment up to 7 bar and 80C. Their replaceable and disposable design ensures ease of maintenance and consistent safety standards for sensitive applications.

FAQs of Filter Catriges:

Q: How do I select the most suitable filter cartridge length and micron rating for my application?

A: Begin by evaluating your systems flow rate, contaminant type and load, and required filtration grade. For higher throughput and longer intervals between replacements, opt for longer cartridges. Match micron ratings (1100 micron) to your specific filtration needs, such as fine water purification or coarse chemical separation.Q: What is the recommended replacement interval for these filter cartridges?

A: Replacement intervals depend on your filtration load and process conditions, but for optimal performance, cartridges should be replaced every 36 months. Heavy-duty operations or high contaminant loads may necessitate more frequent changes.Q: Which seal and end cap materials are available, and how can I choose the best option?

A: Seal materials include Buna-N, EPDM, Silicone, and optionally Viton. End caps are available in polypropylene or stainless steel. Select based on the chemical compatibility and temperature demands of your application to ensure maximum durability and leak prevention.Q: Where are these filter cartridges commonly used?

A: Our cartridges are widely employed in water treatment plants, pharmaceuticals, food & beverage processing, chemical industries, RO plants, oil & gas facilities, and paint manufacturing, among others. Their versatility makes them ideal for both industrial and commercial applications.Q: What are the benefits of using a cartridge filter with a smooth or grooved surface finish?

A: Smooth finishes minimize clogging and are easier to clean in certain environments, while grooved surfaces increase filtration area, enhancing dirt holding capacity and extending service life in demanding filtration tasks.Q: How can I confirm compatibility with FDA regulations?

A: FDA-grade cartridge options are available for critical applications such as food, beverage, and pharmaceuticals. Request documentation from your supplier to verify compliance and ensure the safety of your end products.Q: What steps are involved in replacing a filter cartridge within a system?

A: Shut off flow and relieve system pressure, then open the filter housing. Remove the old cartridge and insert a new one, checking seal and end cap placement for proper fit. Secure the housing and restore system flow, monitoring for leaks or pressure anomalies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

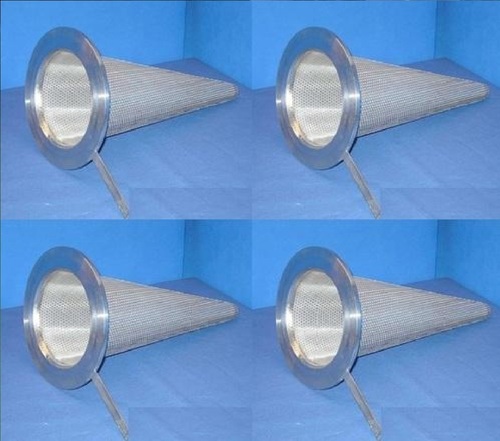

Sintered Mesh Cone Filter

Condition : New

Filter Type : Cone Type / Cartridge

Material : Stainless Steel (SS304/SS316L)

Feature : High dirtholding capacity, uniform pore size distribution, robust structure

Cleaning Method : Other, Backwash, Ultrasonic, Solvent Cleaning

Mesh : Woven wire mesh, multiple layers

Axial Seal HVAC Filters

Condition : New

Filter Type : Panel Filter, Axial Seal

Material : Synthetic Fiber Media, Galvanized Iron Frame

Feature : High dust holding capacity, axial seal design for leakproof operation

Cleaning Method : Other, Nonwashable, Disposable

Mesh : MultiLayer Synthetic Mesh

Hydraulic Filter for 1800 Concrete Pump

Condition : New

Filter Type : Return line filter

Material : Highquality stainless steel and synthetic fibers

Feature : High filtration efficiency for hydraulic systems, suitable for heavyduty concrete pumps

Cleaning Method : Other, Replaceable cartridge, nonwashable

Mesh : Fine filtration mesh (customizable based on requirements)

Filtration Element

Condition : New

Filter Type : Cartridge/Element Type

Material : Stainless Steel

Feature : High filtration efficiency, Easy installation, Durable and rustresistant

Cleaning Method : Other, Backwash / Manual

Mesh : Fine mesh (typically 40 to 200 micron)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS