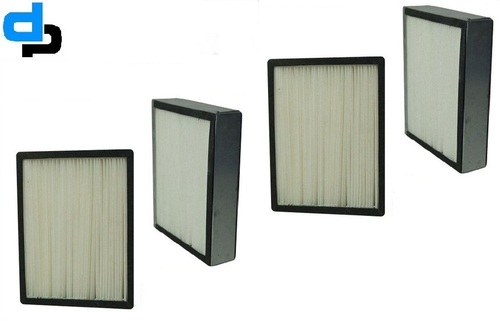

Dry Fabric Panel Type Air Filters

Dry Fabric Panel Type Air Filters Specification

- Efficiency (%)

- 60% - 90% (ASHRAE)

- Cleaning Method

- Periodic cleaning by air or water washing (replace if damaged)

- Flow Rate

- 500 to 2500 CFM (depends on filter size)

- Capacity

- Depends on media & size; suitable for HVAC pre-filtration

- Temperature Range

- Up to 80C

- Pressure

- Initial pressure drop: 20-35 Pa

- Filtration Grade

- Medium

- Filter Type

- Panel Filter

- Media Type

- Dry synthetic fibre

- Connecting Type

- Flange/slide-in type

- Condition

- New

- Material

- Galvanized iron frame with synthetic non-woven dry fabric filter media

- Mesh

- Metal mesh support (typically GI or aluminium) both sides

- Diameter

- Not Applicable (Panel Type)

- Construction

- Panel type, Rigid construction with sturdy frame

- Medium Filter

- Synthetic non-woven fabric

- Weight

- Depends on size (typically 2-8 kg)

- Shape

- Rectangular

- Feature

- High dust holding capacity, Low resistance, Long service life, Easy installation and replacement

- Gasket

- PU foam gasket optional for better sealing

- Maximum Humidity Tolerance

- Up to 100% RH

- Life Span

- Varies, typically 3-6 months depending on environment

- Installation

- Easy to retrofit into standard frames or housings

- Color

- Silver or as per order

- Recommended Usage

- HVAC, ventilation systems, commercial or industrial premises

- Mounting

- Vertical or horizontal

- Frame Thickness

- 25mm / 50mm (customizable)

Dry Fabric Panel Type Air Filters Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- Manipur, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Pondicherry, Nagaland, South India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, All India, Lakshadweep, Delhi, Gujarat, Karnataka, North India, Kerala, Central India, Odisha, West India, Chhattisgarh

About Dry Fabric Panel Type Air Filters

Product description:We are engaged in offering a quality range of Dry Fabric Panel Type Air Filters that is specifically designed for meeting the requirements of nuclear, pharmaceutical, biological, petrochemical, fertilizer and synthetic fiber industries along with computer installation and hospitals. These are available with following specifications:

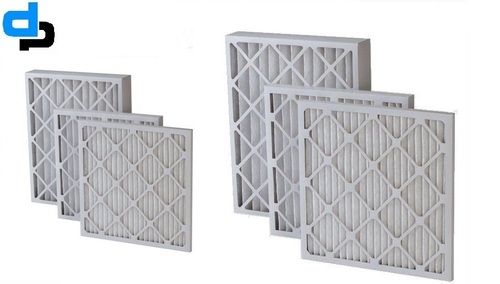

1. Construction:

The filter elements are constructed from special pressed non woven synthetic filter fabric stitched on a G. I wire neon support & rods and crimped to form deep folds

This exclusive design ensures a large filtration area in ratio to the face area of the filter unit. Result-low differential pressure, high dust retention capacity and high flow rate

The filter units are made in standard sizes and are interchangeable. The filter casing is provided with a flanged section for easy fitment on to the filter frame

A felt & neoprene sponge rubber sealing is fixed on to the filter flange. The filter folds are separated by aluminum spacers to ensure uniform distribution of air flow through the filter media - longer service life

The filter element is sealed in to a mild steel casing duly spray painted and stove enameled to counter rust formation. Aluminum filter casings are also available

2. Operating Conditions:

The Filter unit can be used under conditions of humidity up to and including 100% RH. Exclusive design ensures large filtration area, maximum filtration efficiency and nominal pressure drop vis-à-vis airflow rate

It is recommended that the filter element is replaced every 12-18 months

Dry Fabric Panel Filters are essential in all industrial installations where a high degree of filtration efficiency and nominal pressure drop commensurate with rated flow is required

3. Installation:

Filter units may be mounted in multiple banks to cater to large volumes of air flow

The units can be mounted on angle iron frames. Specially designed outlet ducts can be supplied for attaching to the frame work of the filter units for fitment with the existing duct

The filter units are made in standard sizes and are interchangeable

Robust Construction for Demanding Environments

Built with a galvanized iron frame and reinforced with GI or aluminium mesh, these filters stand up to tough industrial and commercial conditions. The rigid construction ensures lasting performance, while the synthetic non-woven dry fabric media delivers reliable medium-grade filtration for HVAC and ventilation applications.

Easy Installation and Customizable Options

Our panel filters are available in two standard frame thicknesses (25mm and 50mm) and a variety of sizes, making them compatible with most standard housings. The slide-in or flange-type connection design, combined with the optional PU foam gasket, ensures quick, leak-free installation and easy retrofitting into existing systems.

Optimized for Efficiency and Longevity

Engineered for high dust holding capacity and low resistance, these filters protect downstream equipment and maintain airflow efficiency. With an initial pressure drop as low as 20-35 Pa and a lifespan of 3-6 months (depending on environment), maintenance is simplejust clean with air or water, and replace if damaged.

FAQs of Dry Fabric Panel Type Air Filters:

Q: How are these dry fabric panel air filters installed into existing systems?

A: These filters are designed for easy retrofitting and direct replacement in standard HVAC and ventilation frames or housings. They support both slide-in and flange-type mounting, suitable for vertical or horizontal installation, ensuring a straightforward setup process.Q: What environments are best suited for using these panel type air filters?

A: These filters are ideal for commercial and industrial premises, particularly in HVAC and ventilation systems where medium-grade air filtration is required. Their robust construction also makes them suitable for environments with high humidity (up to 100% RH) and moderate dust loads.Q: When should I replace or clean the panel air filters?

A: It is recommended to clean these filters periodically using compressed air or water washing, especially if you notice increased resistance or reduced airflow. Typically, replacement should occur every 3-6 months, but this interval depends on specific environmental conditions and usage.Q: Where can these air filters be mounted within a system?

A: These panel filters are versatile and can be mounted in both vertical and horizontal orientations, fitting most HVAC or air handling unit housings. Their rectangular shape and customizable dimensions ensure compatibility with a wide range of equipment.Q: What is the benefit of the optional PU foam gasket?

A: Selecting the PU foam gasket option enhances the filters sealing capability, minimizing air bypass at the frame edges. This leads to improved filtration performance and more consistent air quality within your ventilation or HVAC systems.Q: How does the filters construction contribute to its durability and performance?

A: The galvanized iron frame and metal mesh reinforcement give the filter rigidity and strength, while the synthetic non-woven media ensures high dust capture with low airflow resistance. This combination results in long service life and dependable filtration efficiency.Q: What is the process for periodic cleaning and maintenance of these filters?

A: To maintain optimal performance, clean the filters by blowing compressed air or rinsing with water as needed. Check for physical damage during each maintenance cyclereplace the filter entirely if you notice tears, deformities, or compromised filter media.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Filter Category

Industrial Pre Filters

Flow Rate : 1000 50000 m3/hr (customizable)

Capacity : As per design (customizable)

Construction : Other, Welded/Flanged/Clamped

Temperature Range : 20C to 120C

Feature : High dirt holding capacity, durable construction, easy installation, large surface area

Efficiency (%) : Up to 98%

Microvee Type Fine Filter

Flow Rate : Up to 3400 CFM (cubic feet per minute), depending on filter size

Capacity : Applicationspecific, customisable

Construction : Other, Riveted or welded frame, pockettype filter design

Temperature Range : Up to 80C

Feature : High efficiency, low initial resistance, durable construction, leak proof design

Efficiency (%) : 90 95% (approx) for 5 micron

AC HVAC Filter

Flow Rate : 5002000 CFM

Capacity : High Capacity

Construction : Other, Box/Pleated

Temperature Range : 0C to 80C

Feature : High Dust Holding Capacity, Low Initial Pressure Drop, Easy To Install

Efficiency (%) : Up to 99.97%

Furnace HVAC Filter

Flow Rate : 12003000 m/h (depending on size)

Capacity : High dustholding capacity

Construction : Other, Pleated Panel

Temperature Range : 10C to 80C

Feature : High Dust Holding Capacity, Easy to Install, Durable Construction, Corrosion Resistant Frame

Efficiency (%) : 85%

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free