Microvee Type Fine Filter

Microvee Type Fine Filter Specification

- Connecting Type

- Flange / Custom mount

- Media Type

- Microfine media, multi-vee pockets

- Pressure

- Initial Pressure Drop: 24 mm WG (max 50 mm WG)

- Cleaning Method

- Non-washable, replaceable

- Filter Type

- Microvee Type Fine Filter

- Temperature Range

- Up to 80C

- Efficiency (%)

- 90 - 95% (approx) for 5 micron

- Flow Rate

- Up to 3400 CFM (cubic feet per minute), depending on filter size

- Filtration Grade

- Fine (EN 779: F5 to F9)

- Capacity

- Application-specific, customisable

- Condition

- New

- Material

- Galvanized steel / Aluminium / Stainless Steel frame, microfine synthetic fiber media

- Mesh

- Microvee multi-pocket media

- Diameter

- Custom as per requirement

- Construction

- Riveted or welded frame, pocket-type filter design

- Medium Filter

- Micro-size non-woven synthetic fiber

- Weight

- Light to medium depending on size

- Shape

- Rectangular / Square

- Feature

- High efficiency, low initial resistance, durable construction, leak proof design

Microvee Type Fine Filter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- Assam, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, South India, East India, West India, Andhra Pradesh, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Nagaland, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, All India, Lakshadweep, Uttar Pradesh, Maharashtra, Delhi, Gujarat, North India, Kerala, Central India, Odisha, Chhattisgarh, Karnataka

About Microvee Type Fine Filter

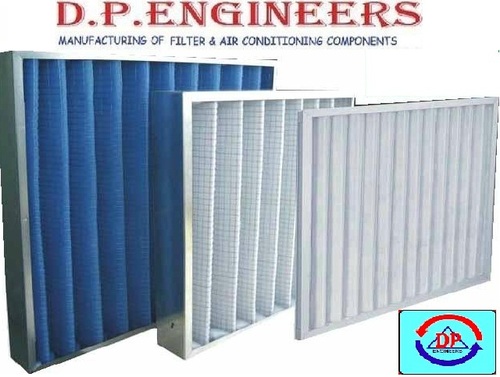

Microvee Type Fine Filter

Specifications:- Material Used: Aluminium anodized

- Flow: Standard Flow

- Size: 610x610x305

- Applications: Industries Like Chemical Process, Food Processing, Electronics

- High Dwell Time

- Low Pressure Drop

- Long Life

- High Dust Holding Capacity

Enhanced Air Filtration for Critical Applications

Ideal for environments with rigorous air purity needs, the Microvee Type Fine Filter provides high-efficiency filtration with minimal pressure drop. Its advanced multi-vee pocket design maximizes dust-holding capacity while maintaining airflow, making it suitable for hospitals, clean rooms, and industrial plants.

Customizable Construction and Easy Installation

Available in customizable sizes, depths, and materials (galvanized steel, aluminum, or stainless steel), this filter is panel or cassette mountable with flange or custom mounting options. Lightweight and robust, it is tailored to fit specific system requirements and offers a secure polyurethane-sealed edge finish.

Low Maintenance, Reliable Performance

With a non-washable, replaceable microfine fiber media, the filter promises consistent performance over its lifespan. It operates efficiently at face velocities of 1.52.5 m/s, managing a flow rate up to 3400 CFM and handling temperatures up to 80C, thereby ensuring durability and ease of upkeep.

FAQs of Microvee Type Fine Filter:

Q: How is the Microvee Type Fine Filter installed and mounted?

A: The filter can be mounted as a panel or cassette, with options for flange or custom mounting to suit your HVAC system or specific equipment layout. Its design allows for flexible integration into existing or new ventilation setups.Q: What is the benefit of choosing a pocket-type multi-vee filter design?

A: The multi-vee pocket design increases the filter surface area, enabling higher dust-holding capacity, uniform airflow, and improved filtration efficiency, which contributes to longer filter life and reduced maintenance frequency.Q: When should the Microvee Type Fine Filter be replaced?

A: Replacement is recommended when the pressure drop across the filter approaches the maximum rated value of 50 mm WG or at intervals suggested by your application or environmental conditions. Regular monitoring ensures optimal performance.Q: Where can this filter be used for maximum efficacy?

A: The filter excels in settings requiring superior air quality, such as clean rooms, pharmaceutical facilities, electronics manufacturing, paint booths, and general industrial ventilation systems.Q: What materials are used in the construction of this filter?

A: A robust frame is constructed from galvanized steel, aluminum, or stainless steel, while the filtration media is made from high-efficiency microfine synthetic fibers, with a sealed polyurethane edge to prevent air bypass.Q: How is the filter maintained and cleaned?

A: The Microvee filter is designed as non-washable and should be replaced rather than cleaned. Routine inspection and timely replacement help maintain system efficiency and indoor air quality.Q: What advantages does this filter offer in industrial environments?

A: Besides high efficiency (up to 95% for 5-micron particles), it offers low initial resistance, long service life, leak-proof sealing, customizable options, and compliance with international air quality standards, ensuring reliable performance in critical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Filter Category

Pre Filters

Minimum Order Quantity : 1 Piece

Filtration Grade : Other, G4

Mesh : Aluminum, Stainless Steel, Synthetic

Material : Galvanized Iron, Stainless Steel Frame

Condition : New

Construction : Other, Rugged Frame with Multilayer Mesh

Industrial Pre Filters

Minimum Order Quantity : 1 Piece

Filtration Grade : Other, Industrial PreFiltration

Mesh : Available in 5 to 100 micron

Material : Stainless Steel

Condition : New

Construction : Other, Welded/Flanged/Clamped

PRE FILTERS Pleated Type

Filtration Grade : Other, G4 (EN779 standard)

Mesh : Available in multiple mesh sizes

Material : Nonwoven synthetic media, galvanized steel frame

Condition : New

Construction : Other, Pleated panel filter with rigid frame

AHU PRE Filters for Dhanbad Jharkhand

Minimum Order Quantity : 25 Pieces

Filtration Grade : Pre Filter

Mesh : HDPE Media / Non Woven Synthetic Media

Material : Galvanized Steel, Aluminum Anodized,SS304

Condition : New

Construction : Box Filter

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS