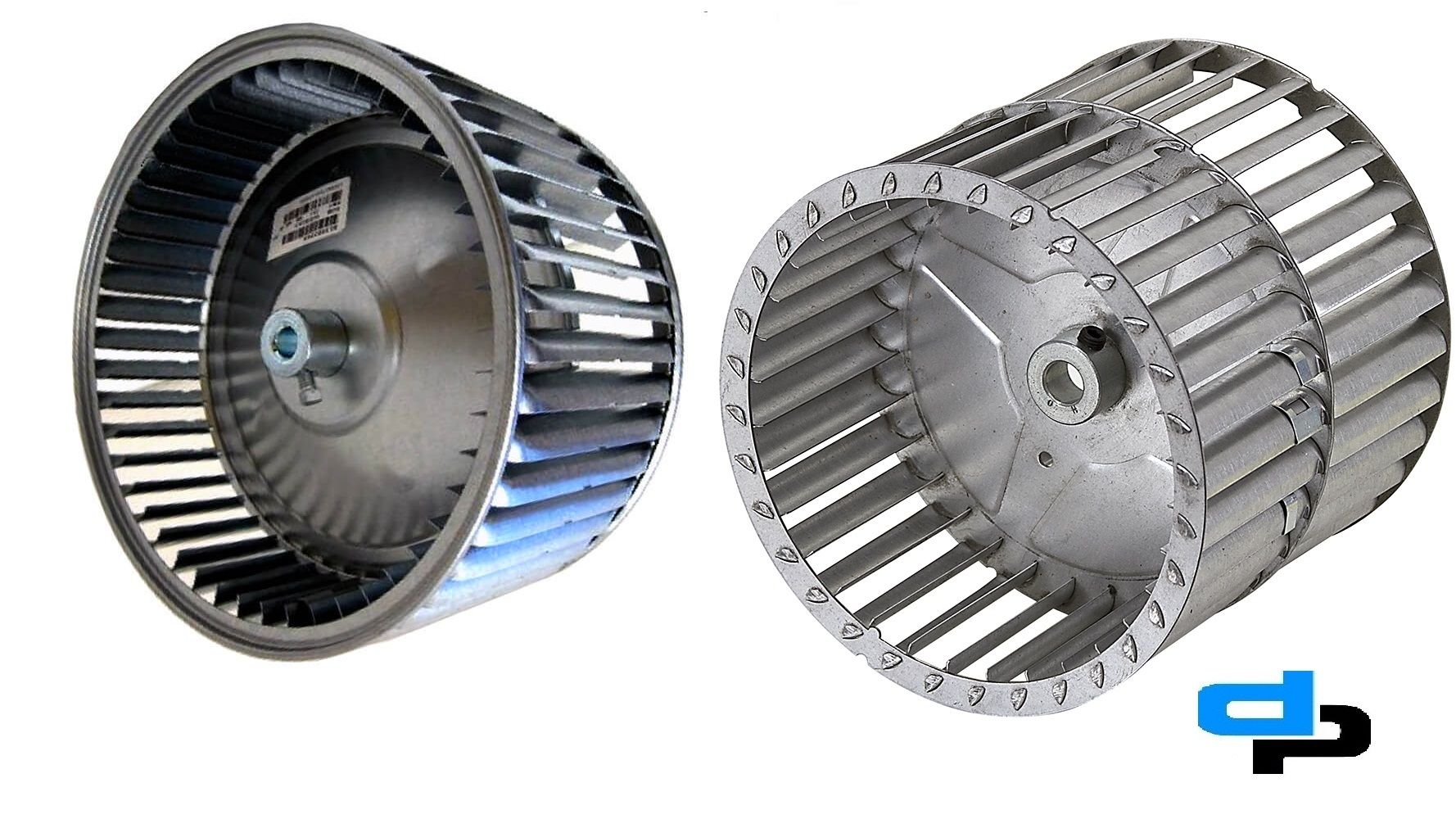

DIDW Centrifugal Fan 455 MM X 380 MM

DIDW Centrifugal Fan 455 MM X 380 MM Specification

- Life Span

- 10,000+ hrs

- Pressure Range

- 60-100 mm WG

- Output Power

- 1.5 kW

- Power

- 1.5 kW

- Max Pressure

- 100 mm WG

- Motor Power

- 2 HP

- Flow Rate

- 1500-2000 m/hr

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel (MS)

- Capacity

- Upto 2,000 m/hr

- Pressure

- Upto 100 mm WG

- Application

- Industrial Ventilation, HVAC, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- 70-75 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- Approx. 38 kg

- Dimension (L*W*H)

- 455 mm x 380 mm

- Color

- Silver Grey

DIDW Centrifugal Fan 455 MM X 380 MM Trade Information

- Minimum Order Quantity

- 2 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Tripura, Manipur, Meghalaya, South India, Central India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Chhattisgarh, Bihar, Delhi, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Uttar Pradesh, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Uttarakhand, Dadra and Nagar Haveli, Gujarat, All India

About DIDW Centrifugal Fan 455 MM X 380 MM

DIDW Centrifugal Fan 455 MM X 380 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 59 | DP 18 15 | 455 X 380 X 365 | 18 X 15 | 30 MM,35 MM,& 1.5 | AL. / GI. |

Robust Performance and Adaptability

Designed for versatility, the DIDW Centrifugal Fan features a forward curved impeller and is capable of both clockwise and counterclockwise rotation. With a base-mounted, belt-driven system and epoxy-coated mild steel construction, it withstands demanding conditions in industrial and HVAC applications across India.

Efficient and Reliable Operation

This centrifugal fan delivers an impressive flow rate of 1,5002,000 m/hr and pressure up to 100 mm WG, powered by a 1.5 kW (2 HP) three-phase motor. Its heavy-duty, grease-lubricated bearings and TEFC motor enclosure maximize reliability and extend the units lifespan to over 10,000 hours.

FAQs of DIDW Centrifugal Fan 455 MM X 380 MM:

Q: How is the DIDW Centrifugal Fan 455 MM x 380 MM installed?

A: The fan is designed for base mounting, allowing secure installation on flat surfaces. Its compact dimensions (455 mm x 380 mm) and manageable weight (approx. 38 kg) facilitate straightforward positioning and connection to existing ventilation or HVAC systems.Q: What are the advantages of a forward curved, balanced impeller?

A: A forward curved, dynamically balanced impeller provides quieter operation, stable airflow, and efficient handling of moderate to high volumes, making this fan suitable for industrial ventilation and air handling applications.Q: When should I select the clockwise or counterclockwise rotation option?

A: The direction of rotation is selected based on your systems airflow requirements and duct configuration. Both clockwise and counterclockwise options are available to accommodate varying setup needs.Q: Where can the DIDW Centrifugal Fan be used?

A: This fan is ideal for installation in industrial ventilation, commercial HVAC systems, and air handling units, supporting environments that require dependable air movement within a moderate temperature range (up to 60C).Q: What is the typical process for maintaining this centrifugal fan?

A: Regular maintenance involves inspecting and lubricating the heavy-duty, grease-lubricated bearings, checking belt tension, and cleaning the impeller and housing to ensure optimal performance and longevity.Q: How does the TEFC (Totally Enclosed Fan Cooled) enclosure benefit the motor?

A: The TEFC enclosure protects the motor from dust, moisture, and contaminants, improving reliability and extending the lifespan of the centrifugal fan, which is especially beneficial for industrial and commercial sites.Q: What key benefits does this fan provide over alternatives?

A: Delivering high airflow capacity, a long service life (10,000+ hours), and robust construction, the DIDW Centrifugal Fan minimizes downtime and maintenance costs, making it a reliable and cost-effective solution for demanding air movement needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 150 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 4080 mm WC

Life Span : 810 Years

Power : 0.75 kW

Power Source : Other, Electric

DIDW Centrifugal Fan 330 MM X 330 MM

Price 8500 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 50 150 mm WG

Life Span : 10 Years (approximate with proper maintenance)

Power : 1 HP

Power Source : Other, Electric

DIDW Centrifugal Fan 300 MM X 254 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 70130 mm WG

Life Span : 810 Years

Power : 2.2 kW

Power Source : Other, Electric

DIDW Centrifugal Fan 455 MM X 305 MM

Price 15000 INR

Minimum Order Quantity : 2 Pieces

Pressure Range : 4080 mm WG

Life Span : 1012 Years

Power : 3.0 kW

Power Source : Other, Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS