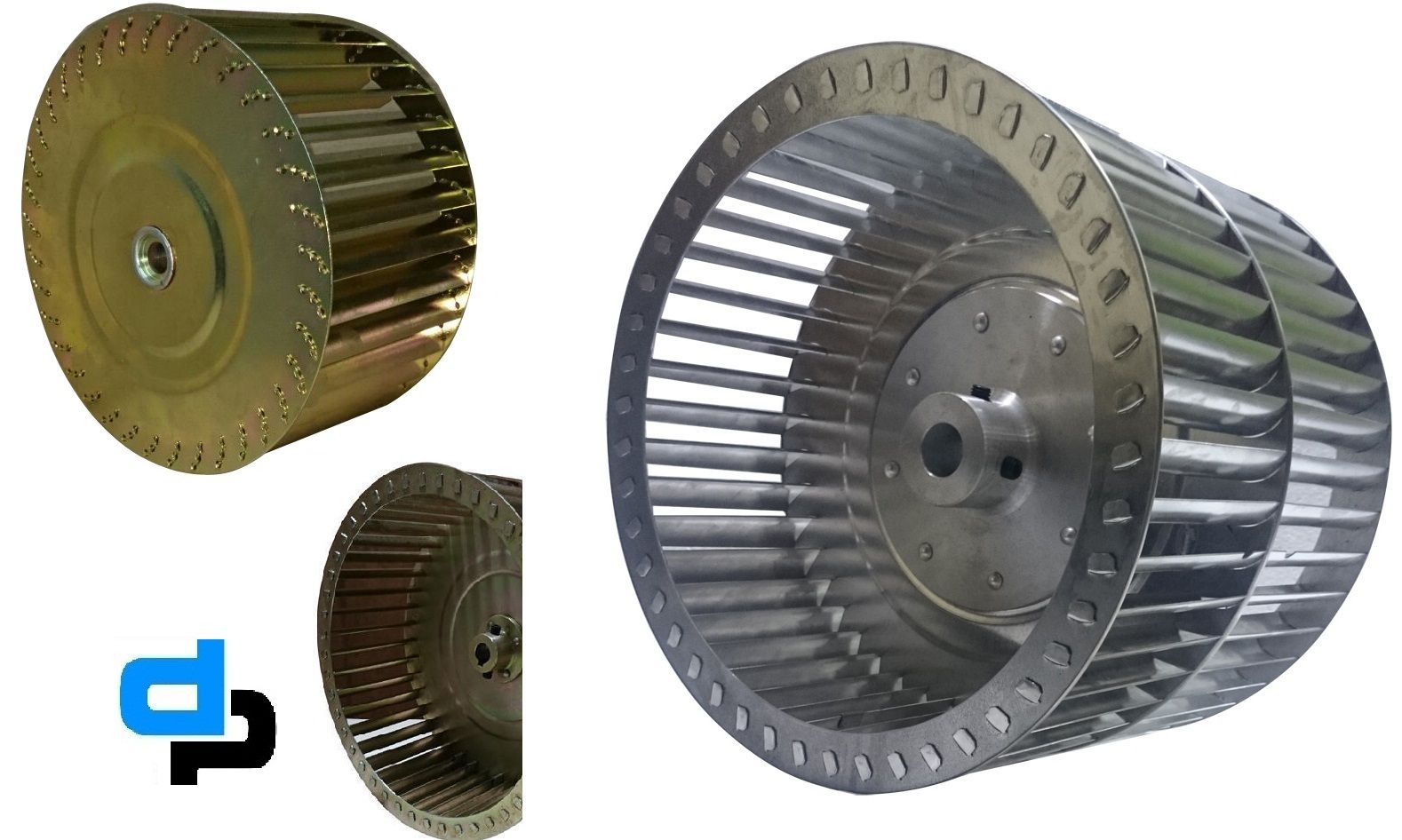

DIDW Centrifugal Fan 250 MM X 150 MM

DIDW Centrifugal Fan 250 MM X 150 MM Specification

- Power

- 0.75 kW

- Motor Power

- 1 HP

- Pressure Range

- 40-80 mm WC

- Flow Rate

- Up to 1200 m/h

- Max Pressure

- 80 mm WC

- Output Power

- 0.75 kW

- Life Span

- 8-10 Years

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 800-1200 m/h

- Pressure

- Up to 80 mm WC

- Application

- Ventilation, Industrial, HVAC Applications

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1400 RPM

- Noise Level

- 75 dB(A)

- Power Source

- Electric

- Voltage

- 220/380 V

- Weight

- Approx. 15 kg

- Dimension (L*W*H)

- 250 mm x 150 mm

- Color

- Grey

DIDW Centrifugal Fan 250 MM X 150 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- South India, North India, East India, West India, Assam, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Meghalaya, Arunachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Andhra Pradesh, Central India, All India

About DIDW Centrifugal Fan 250 MM X 150 MM

DIDW Centrifugal Fan 250 MM X 150 MM

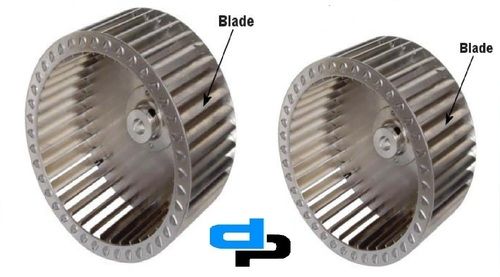

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 36 | DP 10 60 | 250 X 150X 210 | 10 X 6 | 12.70 (1/2) & 15 MM | AL. / GI. |

Features and Specifications

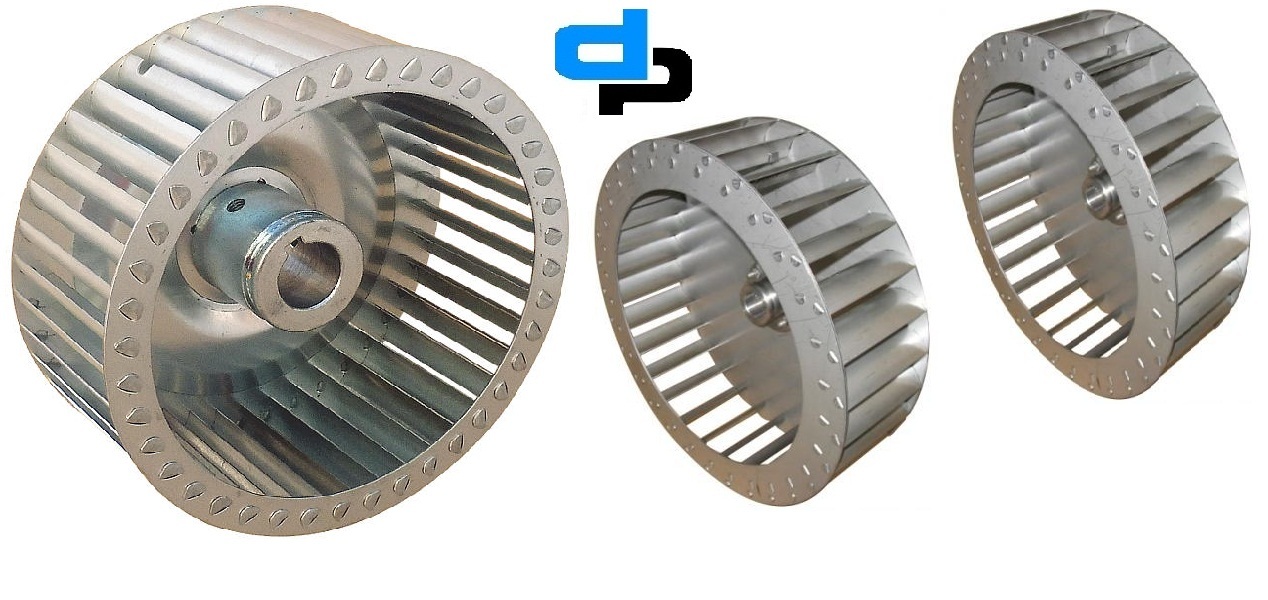

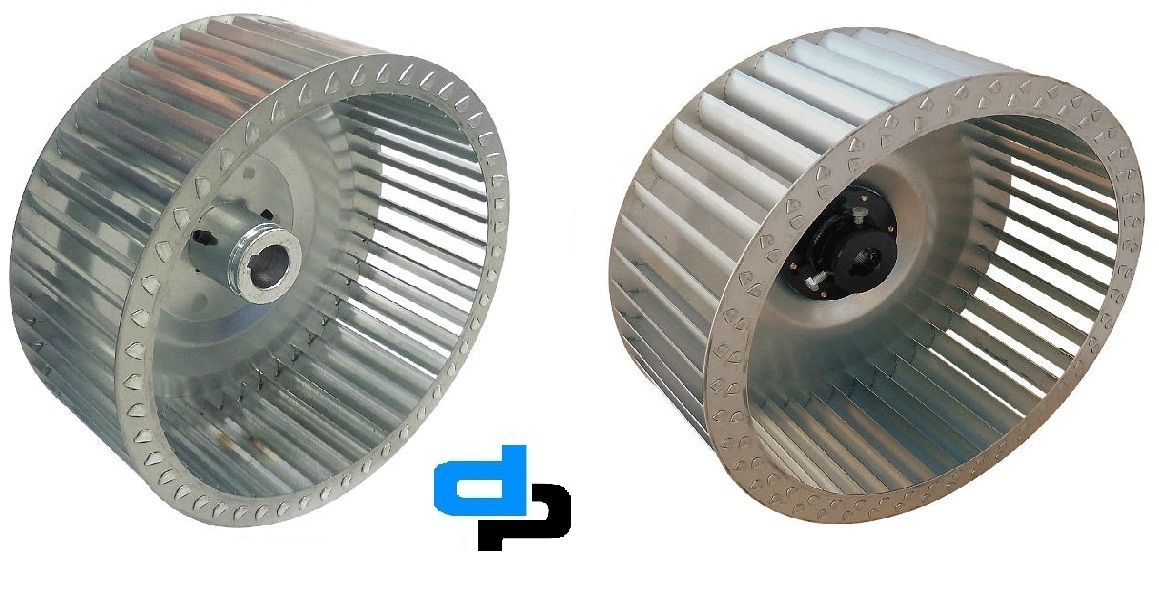

The fan is constructed with mild steel blades in a forward curved impeller design, mounted securely on a base for stability. It offers flexible rotation directions and compatibility with both belt and direct drive types. The unit is protected by an IP55 enclosure, ensuring resilience against dust and water ingress. Operating efficiently between -10C and +60C, the fan delivers a powerful airflow up to 1200 m/h, suitable for demanding industrial, ventilation, and HVAC scenarios.

Applications and Usage

Ideal for ventilation, industrial settings, and HVAC systems, this centrifugal fan excels in maintaining air quality and temperature control in factories, workspaces, and commercial establishments. With its versatile mounting and robust construction, it handles a wide array of air-moving tasks. The quiet operation and extended lifespan make it a dependable solution for continuous or intermittent usage, supporting comfortable and safe working conditions.

Benefits of the DIDW Centrifugal Fan

Employing a forward curved impeller and tough mild steel blades, the fan delivers efficient airflow with minimal noise. Its flexibility in drive types and mounting, together with high pressure capability, enables customized integration into many facility configurations. The IP55 rating protects against harsh environments, while low maintenance requirements and energy-efficient operation contribute to long-term cost savings for users.

FAQs of DIDW Centrifugal Fan 250 MM X 150 MM:

Q: How is the DIDW Centrifugal Fan typically installed in industrial environments?

A: The fan is base mounted and can be integrated into ventilation systems by securing it on a level surface. Installation may involve either a belt or direct drive setup, and electrical connections using the standard 220/380 V supply. Its flexible clockwise or counterclockwise rotation allows proper orientation for airflow needs.Q: What applications are suitable for this centrifugal fan model?

A: This fan is ideal for HVAC systems, industrial ventilation, and general air-moving needs in manufacturing plants, warehouses, and commercial buildings. The robust construction and wide operating temperature range make it suitable for environments requiring reliable and continuous airflow management.Q: Where does the DIDW Centrifugal Fan perform best?

A: The fan is optimally used in settings where efficient air movement and temperature control are vital, such as factories, workshops, and enclosed spaces with high heat or dust generation. Its IP55 enclosure ensures performance even in areas exposed to moisture or particulate matter.Q: What is the process for maintaining the centrifugal fan for long-term use?

A: Routine maintenance includes checking the belt or direct drive assembly, cleaning the blades and enclosure, and ensuring the electric motor operates smoothly. Following manufacturer-recommended procedures, periodic inspections help sustain its lifespan of 810 years and consistent performance.Q: How does the fans forward curved impeller benefit airflow?

A: The forward curved impeller design enhances airflow efficiency, providing stable and consistently high volumes at relatively low sound levels. This improves workplace comfort and air quality while reducing energy consumption for ventilation operations.Q: When should noise levels and pressure range be considered during selection?

A: Noise and pressure specifications should be assessed when installing in environments with sensitive equipment or where low noise operation is critical. The fan maintains noise levels 75 dB(A) and accommodates pressure needs up to 80 mm WC, making it suitable for various pressure and capacity requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 200 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, DIDW Centrifugal Fan

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Industrial Ventilation, Air Handling Units, HVAC Systems

DIDW Centrifugal Fan 230 MM X 228 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, Double Inlet Double Width Centrifugal Fan

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Ventilation, Air Handling Units, HVAC Systems

DIDW Centrifugal Fan 380 MM X 380 MM

Price 10000 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, Double Inlet Double Width Centrifugal Fan

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Ventilation, HVAC, Air Handling Units, Industrial & Commercial Air Movement

DIDW Centrifugal Fan 230 MM X 152 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Product Type : Others, DIDW (Double Inlet Double Width) Centrifugal Fan

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Ventilation, Exhaust, HVAC, Air Handling Units

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS