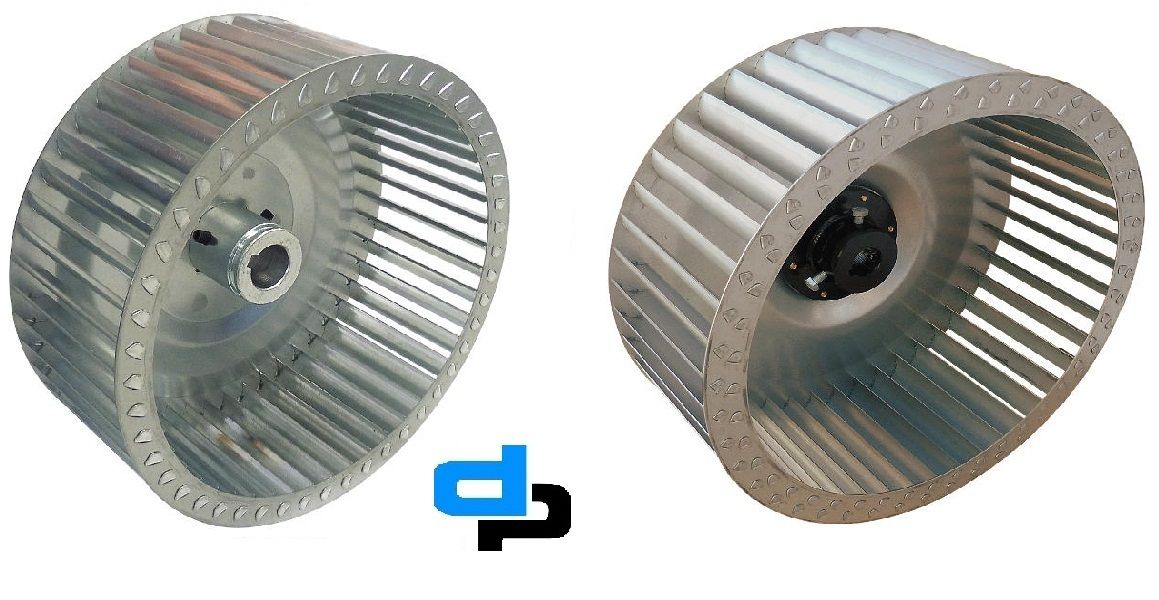

DIDW Centrifugal Fan 300 MM X 254 MM

DIDW Centrifugal Fan 300 MM X 254 MM Specification

- Life Span

- 8-10 Years

- Flow Rate

- 1500-2200 CFM

- Max Pressure

- 130 mm WG

- Output Power

- 2.2 kW

- Motor Power

- 3 HP

- Pressure Range

- 70-130 mm WG

- Power

- 2.2 kW

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1500-2200 CFM

- Pressure

- 70-130 mm WG

- Application

- Industrial Ventilation, HVAC, Exhaust systems, Air handling units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1450 RPM

- Noise Level

- 75 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 28 kg

- Dimension (L*W*H)

- 300 mm x 254 mm x 320 mm

- Color

- Blue

DIDW Centrifugal Fan 300 MM X 254 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Tripura, Manipur, Andaman and Nicobar Islands, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Delhi, Daman and Diu, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Uttar Pradesh, West Bengal, Pondicherry, Uttarakhand, Lakshadweep, Central India, West India, All India

About DIDW Centrifugal Fan 300 MM X 254 MM

DIDW Centrifugal Fan 300 MM X 254 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 49 | DP 12 10 | 300 X 254 X 235 | 12 X 10 | 15 MM,20 MM,25 MM & 1 | AL. / GI. |

Reliable Industrial Ventilation Solution

Designed for industrial settings, the DIDW Centrifugal Fan provides consistent airflow and pressure, supporting ventilation, HVAC, and air handling units. Its backward curved impeller maximizes efficiency while minimizing maintenance, ensuring long-term reliability. The powder-coated mild steel construction offers robust protection against wear and corrosion.

Versatile Functionality and Easy Installation

This fan supports forward or backward airflow, adapting to various system requirements. The base-mounted configuration and flange connection allow for straightforward installation, while the belt-driven mechanism ensures operational flexibility. Users benefit from its low noise level, moderate weight, and compatibility with common electric power standards.

FAQs of DIDW Centrifugal Fan 300 MM X 254 MM:

Q: How is the DIDW Centrifugal Fan typically installed in industrial systems?

A: The DIDW Centrifugal Fan is base mounted and uses flange type connections, making it suitable for integration in HVAC, air handling, and exhaust setups. Its standard dimensions and moderate weight facilitate quick positioning, ensuring secure fixation for stable operation.Q: What maintenance process is recommended for the backward curved impeller and ball bearing mechanism?

A: Regular inspection and lubrication of ball bearings are essential to minimize wear. The backward curved impeller design reduces dust buildup, but periodic cleaning and visual checks help maintain optimal performance and prolong the fans life span of 810 years.Q: When should this centrifugal fan be used over other types?

A: This model is ideal for applications demanding reliable air movement at higher pressures and flow rates, such as industrial ventilation, HVAC, and exhaust systems. The backward curved impeller offers superior energy efficiency and lower noise compared to forward-curved alternatives.Q: Where can the DIDW Centrifugal Fan operate safely regarding temperature and environment?

A: The fan operates efficiently in environments with temperatures ranging from -10C to 80C. Its powder-coated mild steel housing provides resilience against industrial conditions and moderate corrosion, making it suitable for various locations in Indias manufacturing and processing sectors.Q: What are the benefits of the belt-driven and backward curved impeller combination?

A: Belt-driven fans offer adjustability in motor speed for enhanced operational control, while the backward curved impeller maximizes airflow efficiency and reduces power consumption and noise, resulting in cost-effective, reliable performance.Q: How does the insulation class and noise level contribute to its usage in sensitive environments?

A: The Class F insulation ensures thermal protection for the motor, allowing safe operation even in demanding industrial settings. With a noise level of 75 dB(A), the fan operates quietly enough for use in workplaces with strict noise requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 100 MM X 100 MM

Price 750 INR

Minimum Order Quantity : 5 Pieces

Frequency (MHz) : 50 Hz

Voltage : 230 V

Application : Other, Ventilation, HVAC, Dust Extraction

Material : other , Mild Steel

DIDW Centrifugal Fan 250 MM X 150 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Frequency (MHz) : 50 Hz

Voltage : 220/380 V

Application : Other, Ventilation, Industrial, HVAC Applications

Material : other , Mild Steel

DIDW Centrifugal Fan 250 MM X 178 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Frequency (MHz) : 50 Hz

Voltage : 230 V AC

Application : Other, Ventilation, HVAC, Air Handling Units, Industrial Use

Material : other , Mild Steel

DIDW Centrifugal Fan 610 MM X 455 MM

Price 21000 INR

Minimum Order Quantity : 2 Pieces

Frequency (MHz) : 50 Hz

Voltage : 415 V AC

Application : Other, Industrial ventilation, HVAC, Air handling units

Material : other , Mild Steel / Galvanized Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS