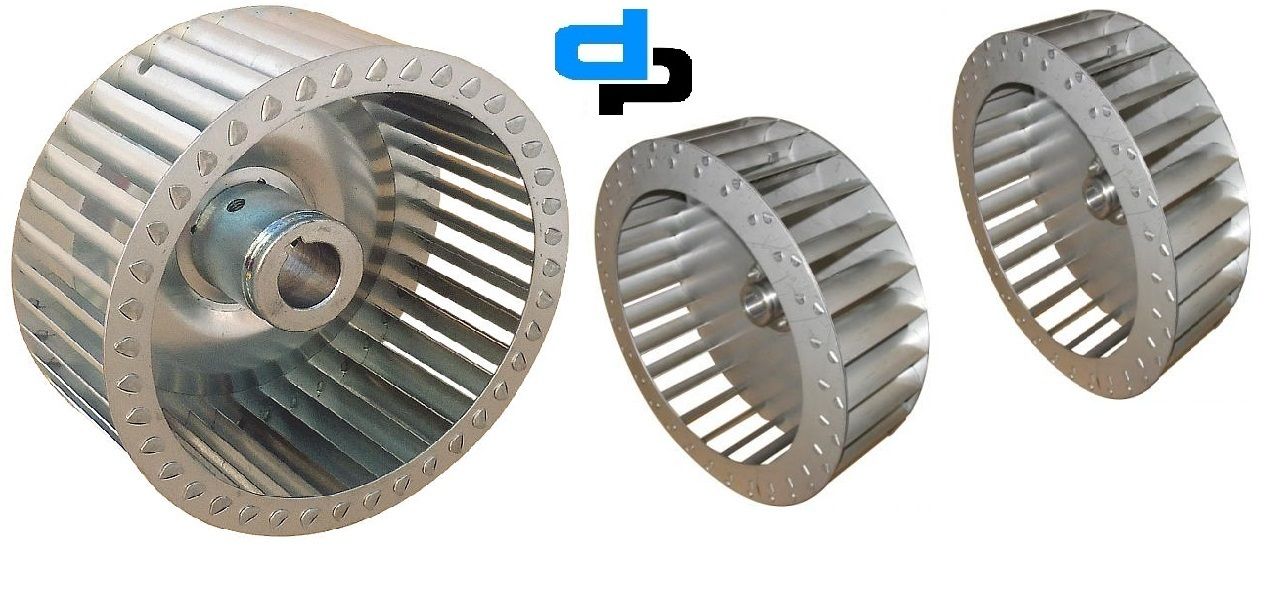

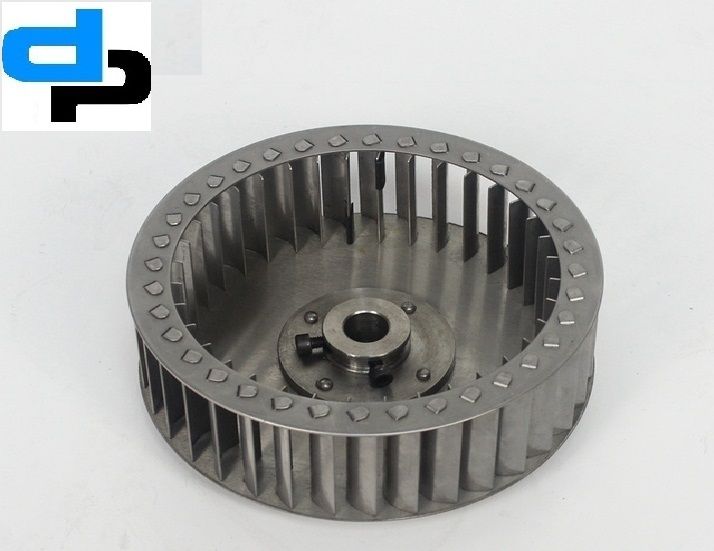

DIDW Centrifugal Fan 250 MM X 178 MM

DIDW Centrifugal Fan 250 MM X 178 MM Specification

- Power

- 0.37 kW

- Motor Power

- 0.5 HP

- Pressure Range

- 30-50 mm WG

- Life Span

- More than 5 Years

- Flow Rate

- 800-1000 CFM

- Output Power

- 0.5 HP

- Max Pressure

- 50 mm WG

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- Up to 1000 CFM

- Pressure

- Up to 50 mm WG

- Application

- Ventilation, HVAC, Air Handling Units, Industrial Use

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <75 dB

- Power Source

- Electric

- Voltage

- 230 V AC

- Weight

- Approx 12 kg

- Dimension (L*W*H)

- 250 mm x 178 mm x 250 mm

- Color

- Silver Grey

DIDW Centrifugal Fan 250 MM X 178 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Meghalaya, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, Madhya Pradesh, Central India, All India

About DIDW Centrifugal Fan 250 MM X 178 MM

DIDW Centrifugal Fan 250 MM X 178 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 37 | DP 10 70 | 250 X 178X 210 | 10 X 7 | 12.70 (1/2) & 15 MM | AL. / GI. |

Efficient Performance and Versatility

The DIDW Centrifugal Fan combines high airflow capacity with adaptability across various installation needs. Its backward curved impeller optimizes energy use for ventilation, HVAC, and industrial applications, enabling both clockwise and counterclockwise operation. Users benefit from flexible motor speed and pressure options that suit diverse requirements.

Durable Build for Demanding Environments

Constructed from powder-coated galvanised iron and mild steel, the fan ensures resistance to harsh operating conditions, humidity levels up to 95% RH, and temperatures up to 60C. Ball bearings and a Totally Enclosed Fan Cooled (TEFC) motor enhance longevity, offering a life span of more than five years with reliable operation under continuous use.

Easy Installation and Maintenance

The base-mounted design, compact dimensions (250 mm x 178 mm x 250 mm), and easy service access allow for straightforward installation and upkeep. The fan supports both belt drive (optional) and direct motor drive, making it suitable for retrofit or new installations in varied environments.

FAQs of DIDW Centrifugal Fan 250 MM X 178 MM:

Q: How can I install the DIDW Centrifugal Fan in my facility?

A: The fan is base mounted for secure and easy installation. Its compact size and accessible design allow it to be integrated into existing ventilation or HVAC systems, and it can be configured for either single-phase or three-phase operation to match your electrical setup.Q: What benefits does the backward curved impeller type provide?

A: A backward curved impeller ensures higher energy efficiency, reduced noise levels, and maintains optimal airflow even at varying pressures, making it suitable for industrial and commercial air handling tasks.Q: When should the fan be serviced or maintained?

A: Scheduled maintenance is recommended at regular intervals depending on usage intensity. The easy-service access design simplifies inspection, cleaning, and replacement of parts, helping to maintain efficient operation and extend equipment life.Q: Where can the DIDW Centrifugal Fan be used?

A: It is ideal for ventilation, HVAC systems, air handling units, and general industrial applications. The rugged build and high humidity tolerance make it suitable for diverse settings such as factories, warehouses, commercial buildings, and public utility spaces.Q: What is the process for changing the fans direction of rotation?

A: The fan supports both clockwise and counterclockwise rotation. Direction can be altered by adjusting wiring connections according to the motor specifications, enabling flexibility for airflow management without major modifications.Q: Is there an option for belt drive operation, and what advantage does it offer?

A: Yes, the DIDW Centrifugal Fan can be equipped with a belt drive as an option. Belt drives allow for greater flexibility in speed control and can meet specific application requirements where direct coupling is not ideal.Q: What are the primary benefits of choosing this fan for my facility?

A: Key benefits include robust performance in high humidity and temperature, low noise operation (<75 dB), easy servicing, long lifespan, and ISO 9001 certified quality standards, making it a dependable choice for critical airflow needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 160 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, HVAC, Ventilation, Industrial Cooling

Product Type : Others, DIDW Centrifugal Fan

Frequency (MHz) : 50 Hz

Power Source : Other, Electric

DIDW Centrifugal Fan 230 MM X 203 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Application : Other, Ventilation, Air Conditioning, Industrial exhaust

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Frequency (MHz) : 50 Hz

Power Source : Other, Electric

DIDW Centrifugal Fan 530 MM X 380 MM

Price 18500 INR

Minimum Order Quantity : 2 Pieces

Application : Other, Ventilation, HVAC Systems, Industrial Air Circulation

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Frequency (MHz) : 50 Hz

Power Source : Other, Electric

DIDW Centrifugal Fan 610 MM X 530 MM

Price 22000.00 INR

Minimum Order Quantity : 1 Piece

Application : Other, HVAC, Air Handling, Industrial Ventilation, Exhaust Systems

Product Type : Others, Double Inlet Double Width (DIDW) Centrifugal Fan

Frequency (MHz) : 50 Hz

Power Source : Other, Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS