Lube Oil Filters

Lube Oil Filters Specification

- Connecting Type

- Threaded

- Pressure

- Up to 12 Bar

- Temperature Range

- -25C to +120C

- Cleaning Method

- Replaceable

- Media Type

- Synthetic/Cellulose

- Filter Type

- Spin-On / Cartridge

- Filtration Grade

- Medium to Fine

- Efficiency (%)

- Up to 99%

- Flow Rate

- 20 - 120 LPM

- Capacity

- Customizable

- Condition

- New

- Material

- Stainless Steel, Microglass Fiber, Paper

- Mesh

- 5 to 40 Micron

- Diameter

- 70 - 150 mm

- Construction

- Cartridge Type

- Medium Filter

- Lube Oil

- Weight

- 250 - 500 g

- Shape

- Cylindrical

- Feature

- High Dirt Holding Capacity, Corrosion Resistant, Easy to Install

Lube Oil Filters Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Lube Oil Filters

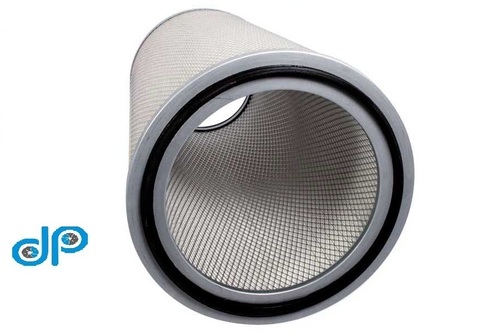

Lube Oil Filters

Product Description:

Specifications:

- Media: Inorganic,

- metal fibre and mesh,

- micro glass, glass fibre,

- chrome nickel,

- nylon

- Type:

- Low and high pressure

Features:

- Sturdiness

- Durability

- Dimensional accuracy

Versatile Performance for Demanding Applications

Engineered for use in automotive systems, industrial machinery, compressors, and hydraulic circuits, our lube oil filters efficiently manage mineral and synthetic oils. Their corrosion-resistant materials, including stainless steel and microglass fiber, ensure endurance even in challenging environments, while the 5 to 40 micron filtration meshes capture contaminants, extending equipment lifespans and minimizing downtime.

High Durability and Safety Standards

Every filter is built to withstand high pressurescollapse pressure resistance up to 10 bar and burst pressure above 20 barensuring safety. Compatibility with ISO 16889 and ISO 4548-12 attests to their rigorous performance. Their robust cartridge and spin-on construction makes maintenance straightforward, while threaded connections simplify installation and replacements.

Outstanding Efficiency and Service Life

Our filters boast filtration efficiency rates up to 99%, handling flow rates ranging from 20 to 120 LPM. Designed as replaceable cartridges, they require no cleaning, providing extended service intervals of up to 5000 hours depending on operational conditions. This makes them an ideal, low-maintenance solution for diverse industrial and automotive applications.

FAQs of Lube Oil Filters:

Q: How do I select the right lube oil filter for my equipment?

A: To choose the suitable lube oil filter, consider operating pressure, flow rate, filtration grade (540 micron), and compatibility with your oil type (mineral or synthetic). Also, check the filters dimensions, end cap material, and ensure it fits your applications ISO 16889 or ISO 4548-12 requirements.Q: What is the recommended process for replacing the filter?

A: Replacement involves shutting down the system, unscrewing the old filter (spin-on or cartridge type), ensuring the seal area is clean, and installing the new filter using the threaded connection. Always ensure that the new filter matches the required specifications and ratings for safe operation.Q: When should the lube oil filter be replaced?

A: Replacement intervals depend on the specific application and oil cleanliness but typically occur every 5000 hours of operation or sooner if there are signs of reduced flow, increased pressure drop, or oil contamination. Always follow your equipment manufacturers guidelines for optimal results.Q: Where can these lube oil filters be used?

A: These filters are suitable for various environments, including automotive engines, industrial machinery, compressors, and hydraulic circuits. Their robust construction and wide temperature range (-25C to +120C) make them versatile for challenging operational conditions.Q: What benefits do these filters offer over standard models?

A: Key benefits include high dirt holding capacity, corrosion resistance, efficiency up to 99%, and a customizable capacity. Their durable materialsaluminum, steel, microglass fibercombined with compliance to international ISO standards, ensure longevity and reliable performance in demanding scenarios.Q: How does the filter protect against system failure?

A: The filter removes harmful particulates from oil, preventing blockages and abrasion within machinery. High burst pressure resistance (>20 bar), durable construction, and effective bypass valve settings (1.22.5 bar) help protect systems from catastrophic failure even in high-stress conditions.Q: What is the installation process for these filters?

A: Installation is straightforward: position the filter in its housing, align the threaded connections, and tighten securely. Ensure seals are properly seated and test for leaks after installation. Regular inspection and timely replacement ensure consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Turbine Air Intake Filters Category

Industrial Gas Filter

Efficiency (%) : 99.5%

Material : Stainless Steel

Construction : Other, Seamless welded body

Shape : Cylindrical

Connecting Type : Flanged

Feature : High dirt holding capacity, Robust construction, Easy installation

Hydraulic Filter for 1800 Concrete Pump

Efficiency (%) : 99%

Material : Highquality stainless steel and synthetic fibers

Construction : Other, Robust cylindrical cartridge design

Shape : Cylinder

Connecting Type : Other, Threaded or flanged end connection

Feature : High filtration efficiency for hydraulic systems, suitable for heavyduty concrete pumps

CYLINDRICAL FILTER CARTRIDGE

Efficiency (%) : Up to 99%

Material : Stainless Steel, Mild Steel

Construction : Other, Seamless Cylindrical Design

Shape : Cylindrical

Connecting Type : Other, Threaded End, Flanged End

Feature : High Dirt Holding Capacity, Easy Installation and Replacement, Durable Construction

Air Filters

Efficiency (%) : High

Material : Metal Frame with Filtration Media

Construction : Other, Mesh and Filter Medium

Shape : Cylindrical

Connecting Type : Other, Flange type

Feature : Reliable Durable

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS