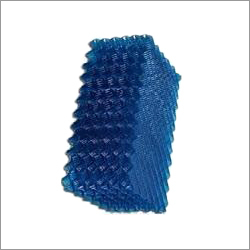

PVC Film Fill

PVC Film Fill Specification

- Material

- Premium grade PVC (Polyvinyl Chloride) film

- Application

- Cooling towers, industrial process cooling, HVAC systems

- Air Flow

- Optimized for efficient cooling tower operations

- Condition

- Brand New

- Type

- Film Fill Media

- Dimension (L*W*H)

- 1200 mm x 300 mm x 150 mm (custom sizes available)

- Cooling Type

- Evaporative Cooling

- Water Flowing Rate

- Up to 20 m/hr (repeat value as placeholder)

- Noise Control

- Low Noise Enhanced Design

About PVC Film Fill

PVC Film Fill is the evaporative cooling pad is cellulose material impregnated with insoluble anti-rot salts and rigidifying saturates. The material has spatial crossing linking technology with high absorbability. It is water resistant, anti-mildew and has a long service life.

We offer good quality cooling pads, which have the following features:

- Lower operating cost

- Comfortable habitation

- Higher productivity

- No water carry-over

- Strong and self supporting

- Dirt resistant

- Low maintenance

- Comfort cooling

- Vegetable storage

- Mushroom farming

- Seed farming

- Dairy farms

Technical Specifications

| 600mmx300mmx150mm |

|

| PVC honey combs. | 25mm {12. 5 + 12. 5}. |

| Corrugation pitch. | 2. 8 mm. |

| Corrugation depth | 3 mm |

| Spiral angles. | 21 |

| No of pvc sheets per 150 mm width | 12 |

| Heat transfer area/cu. Ft. Of fills volume | 1 cu. Ft. |

| Thickness of finished fills. | 0. 30 mm |

| Heat distortion temp. For normal pvc | 60 º c |

| For high grade. | 80 º c { upto 120 º c } |

| Weight of std. Fills. | 800 gm to 1 kg. |

Enhanced Cooling Performance

Our PVC Film Fill is designed to maximize heat exchange with its 20 mm corrugation and honeycomb structure, ensuring high surface area contact for optimal cooling efficiency in cooling towers and HVAC systems. This contributes to lower operational costs and improved system performance in industrial and commercial environments.

Built for Longevity and Safety

Equipped to perform under continuous temperatures up to 55C, this film fill is manufactured with UV-resistant additives and meets IS 15909 flame-retardancy standards. Enjoy up to 8 years of reliable service life, even in demanding outdoor settings, thanks to robust premium-grade PVC construction.

Simple Maintenance and Versatile Installation

Installation is straightforward due to the stackable, modular design. Maintenance is equally simple periodic water spraying is sufficient. The fills low fouling properties and custom sizing availability make it adaptable for new or retrofitted cooling tower and HVAC projects.

FAQs of PVC Film Fill:

Q: How is the PVC Film Fill installed in cooling towers?

A: The honeycomb-structured PVC Film Fill is stackable and easy to assemble, allowing for straightforward installation in both new and existing cooling tower systems. Modular design ensures flexibility for various configurations.Q: What are the key benefits of using this film fill in industrial cooling applications?

A: This film fill provides high surface area for increased heat transfer, high packing density for efficient use of space, low noise operation, and robust temperature and flame-resistance, making it ideal for cooling towers and process cooling.Q: When should I consider cleaning or maintaining the PVC Film Fill?

A: Maintenance is recommended periodically or when a noticeable decrease in cooling performance occurs. The fill is designed for low fouling and can be easily cleaned with a simple water spray, ensuring ongoing efficiency.Q: Where can this film fill be used apart from cooling towers?

A: In addition to cooling towers, the PVC Film Fill is suitable for HVAC systems, industrial process cooling, and any application requiring efficient evaporative cooling and enhanced noise control.Q: What is the maximum operating temperature and service life of this film fill?

A: The film fill is rated for continuous operation at temperatures up to 55C, and under recommended conditions, it has a service life of up to 8 years.Q: How does the cross fluted/vertical fluted design impact performance?

A: These specialized designs improve air-water mixing, enable better water distribution, and enhance thermal performance, resulting in optimized cooling tower operation.Q: What customization options are available for this product?

A: The film fill is available in standard blue as well as customized shades and dimensions to fit different project requirements and aesthetic preferences.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Tower Spare Parts Category

63 mm PVC splash cap cooling Towers Nozzle in Karnataka

Minimum Order Quantity : 2000 Pieces

Condition : New

Application : Live stocks Greenhouses Gas Turbine Pre Cooler For Air Cooled Condenser Spray Painting Booth Industrial Applications Commercial Applications Humidification.

Dimension (L*W*H) : 63 Millimeter (mm)

Cooling Tower Aluminium Fans 1000 MM 6 Blade

Price 12000 INR / Piece

Minimum Order Quantity : 5 Pieces

Condition : New

Material : Aluminum

Application : Cooling Tower

Dimension (L*W*H) : 1000 Millimeter (mm)

Cooling Tower Aluminium Fans 700 MM 4 BLADE

Price 6500 INR / Piece

Minimum Order Quantity : 4 Pieces

Material : Aluminum

Application : Cooling Tower

PVC Fills

Condition : New

Material : Other , PVC (Polyvinyl Chloride)

Application : Cooling Towers, Heat Exchangers, HVAC Systems

Dimension (L*W*H) : 1200 mm x 600 mm x 150 mm (typical), customizable as required

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS