63 mm PVC splash cap cooling Towers Nozzle in Karnataka

63 mm PVC splash cap cooling Towers Nozzle in Karnataka Specification

- Application

- Live stocks Greenhouses Gas Turbine Pre Cooler For Air Cooled Condenser Spray Painting Booth Industrial Applications Commercial Applications Humidification.

- Condition

- New

- Usage

- pharmaceutical,Hotel,Malls,Hospital,OT,POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE,Pharmaceutical Manufacture,Food And Beverages Industry,Pulp And Paper Industry,Textile Industry

- Type

- pvc

- Dimension (L*W*H)

- 63 Millimeter (mm)

- Size

- 63 mm

- Product Type

- 63 mm PVC splash cap cooling Towers Nozzle in Karnataka

- Cooling Type

- cooling tower

- Color

- white

- Nozzle Material

- pvc

63 mm PVC splash cap cooling Towers Nozzle in Karnataka Trade Information

- Minimum Order Quantity

- 2000 Pieces

- FOB Port

- Delhi

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Packaging Details

- E-mail : dpsharma74@yahoo.co.in, dpsharma1974@gmail.com, dpsharma949@gmail.com Mr D.P.SHARMA 9871014210 WhatsApp number :9871014210,9268631221 Websites : www.dpengineers.in, www.dpengineer.in, www.dpengineers.co.in, www.dpengineer.co.in, www.dpengineersindia.com, www.dpengineerindia.com, www.dpengineersindia.in, www.dpengineers.info, www.dpengineer.info, www.dp-engineers.com, www.dpengineerindia.in, www.dpengineersindia.net, www.dpengineersdelhi.co.in, www.dpengineersdelhi.com, www.dp-engineers.co.in, www.dpengineersdelhi.net, https://www.exportersindia.com/dpengineers

- Main Export Market(s)

- Asia, Middle East

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About 63 mm PVC splash cap cooling Towers Nozzle in Karnataka

In order to meet the various requirements of our esteemed clients, we are engaged in manufacturing and supplying the best qualityPVC Splash Caps. The offered products are fabricated utilizing the best quality raw material and modern techniques under the supervision of skilled professionals as per the set industry norms. Further, we offer these products to our esteemed clients at cost-effective prices.

Features:

-

Perfect finish

-

Precise dimensions

-

Reliability

-

Applications:

- Aluminum Die casting

- Air Compressors

- AC Plant & Cold Rooms

- Blow Molding

- Chemical Industries

- Dairy, Citrus and Other Food Processing Industries

- Distilleries and Breweries Plants

- Diesel/Gas Gen sets & Megawatt Projects

- Glass Manufacturing Plants

- Herbal, Aromatic & Extraction Plants

- Industrial Heat Process

- Plastic Injection Molding

- PVC Pipes Plant

- Soap/Cosmetic Industries

- Steel Factory and Foundry

Versatile Cooling Solution for Multiple Industries

This 63 mm PVC splash cap nozzle is designed to support a variety of sectors, including power generation, pharmaceuticals, food and beverage processing, agriculture, and commercial buildings. Its adaptable design ensures compatibility with different cooling systems, ensuring robust performance wherever installed.

Constructed for Long-Term Durability

Produced using high-quality PVC material, the nozzle withstands challenging operational conditions, from chemical exposure to intense water pressures. Its corrosion resistance guarantees it maintains its structural integrity and consistent cooling performance over time.

FAQs of 63 mm PVC splash cap cooling Towers Nozzle in Karnataka:

Q: How is the 63 mm PVC splash cap cooling tower nozzle installed?

A: Installation involves securely fitting the 63 mm nozzle in the designated cooling tower location using suitable mounting hardware, ensuring proper alignment to distribute water evenly for optimal cooling.Q: What benefits does the splash cap design provide in cooling towers?

A: The splash cap maximizes water breakup into fine droplets, increasing the contact area between water and air, which enhances heat exchange efficiency and improves the overall cooling process.Q: Where can this PVC cooling tower nozzle be effectively used?

A: The nozzle is suitable for use in power plants, pharmaceutical facilities, hotels, malls, hospitals, cement plants, fertilizer and steel plants, textile and pulp industries, as well as food and beverage processing, spray painting booths, humidification systems, and greenhouses.Q: What makes PVC an ideal material for this nozzle?

A: PVC offers excellent resistance to corrosion, chemicals, and harsh operational environments, ensuring lower maintenance requirements and longer operational lifespan compared to many metals.Q: When should a cooling tower nozzle be replaced?

A: It is advisable to inspect and replace the nozzle if there are signs of clogging, wear, physical damage, or reduced cooling efficiency to maintain optimal system performance.Q: What processes benefit most from using these nozzles?

A: Processes requiring effective water coolingsuch as live stock environments, gas turbine pre-cooling, air-cooled condenser systems, and industrial humidificationbenefit from the nozzles even water distribution and robust construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Tower Spare Parts Category

Cooling Tower Aluminium Fans 600 MM 4 BLADE

Material : Aluminum

Type : Cooling Tower

Condition : New

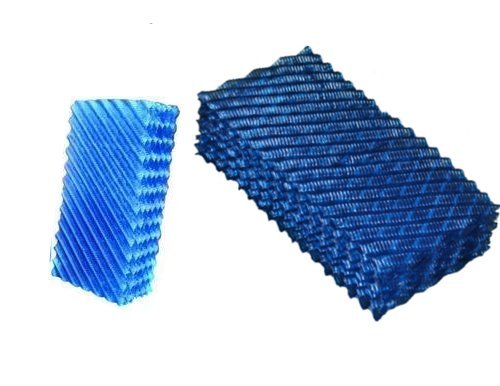

Honeycomb Fills For Cooling Tower

Material : PVC

Type : Honeycomb Fills

Condition : New

Application : Cooling Tower

Water Flowing Rate : High Efficiency

Cooling Type : Evaporative Cooling

PVC Fill

Material : Other , PVC (Polyvinyl Chloride)

Type : Cooling Tower Fill / PVC Fill Pack

Condition : New

Application : Cooling towers, water treatment

Water Flowing Rate : Suitable for high and low velocity water

Cooling Type : Water Cooling

Drift Eliminator

Material : PVC

Type : Drift Eliminator

Condition : New

Application : Cooling towers HVAC systems

Water Flowing Rate : Varies with application

Cooling Type : Evaporative cooling

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS