Non Return Damper

Non Return Damper Specification

- Cleaning Method

- Manual

- Capacity

- Designed per System Requirement

- Connecting Type

- Flanged or Slip-on

- Pressure

- Up to 2500 Pa

- Efficiency (%)

- >95% for Reverse Flow Prevention

- Filter Type

- Non-Return/Backdraft Damper

- Media Type

- Air

- Flow Rate

- Up to 20,000 CFM

- Temperature Range

- -10C to +80C

- Condition

- New

- Material

- Galvanized Steel / Mild Steel / Stainless Steel

- Diameter

- Available from 100 mm to 1000 mm

- Construction

- Welded Frame with Pivoted Blades

- Weight

- Depends on Size (Approx. 3-15 kg)

- Shape

- Rectangular / Circular

- Feature

- Corrosion Resistant, Adjustable Blades, Low Maintenance, Leak Proof

About Non Return Damper

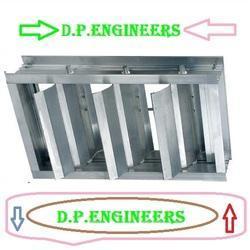

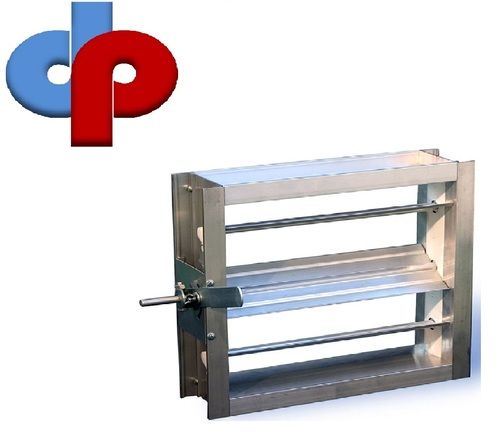

Non Return Damper

- Frame is constructed from galvanized steel sheet. Welded joints are protected by aluminium spray coating.

- Air operated damper blades are fixed to the frame by self oiling nylon bushes with 8 mm dia aluminium pipes.

- Blades are sealed with foam gasket at the bottom to avoid rattling noise and to provide air tight operation.

- Blades open full or to any angle depending on the air velocity. Blades stay in position of opening without fluctuating when there is constant air flow. Blades closes quietly when the air flow stops.

- Designed to maintain a constant pressure level inside pressurized rooms. Used at duct outlets to prevent back draft when air moving devices are switched off.

- In a multi fan installation non return dampers prevent back draft through the operating fans.

- Structure is available with flanged edges and are supplied un drilled as standard.

- Available in square and rectangular sizes.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Precision Control for Airflow

Engineered for applications in ventilation, air handling units, and exhaust systems, our non-return damper is constructed to minimize leakage (less than 2% at rated pressure) and deliver reliable airflow control. Whether you need to prevent reverse flow or enhance energy efficiency, this damper ensures seamless operation under varying pressures and temperatures.

Versatile Design, Lasting Performance

Choose from gravity or spring-loaded blade mechanisms to suit your system needs. Low-maintenance and corrosion-resistant finishes, together with welded frames, provide durability. The damper accommodates both flanged and slip-on connections, and supports rectangular or circular ducts ranging from 100 mm to 1000 mm in diameter.

FAQs of Non Return Damper:

Q: How does the non return damper prevent reverse airflow in HVAC and ventilation systems?

A: The damper uses gravity or spring-loaded blades that automatically close when air attempts to flow in the reverse direction. This design ensures over 95% prevention of backdraft, safeguarding your system from unwanted air movement.Q: What are the installation options for this damper?

A: This non-return damper can be mounted either horizontally or vertically, making it adaptable for various duct orientations in air handling, ventilation, or exhaust systems.Q: When is it recommended to use a galvanized or powder-coated surface finish?

A: Galvanized finishing is ideal for highly corrosive environments due to its enhanced rust resistance, while powder coating provides a durable, attractive surface suitable for most indoor installations.Q: Where can these dampers be used effectively?

A: They are well-suited for use in ventilation networks, HVAC systems, air handling units, and exhaust ducts, particularly where preventing reverse airflow is crucial for operational efficiency.Q: What is the cleaning and maintenance process for the damper?

A: Cleaning is performed manually. Regular inspection and periodic manual cleaning of the blades and housing ensure low maintenance and sustained efficiency.Q: What are the available customization options?

A: Dampers are available in circular or rectangular shapes, with diameters from 100 mm to 1000 mm. Size and material can be tailored according to the clients system requirements.Q: What are the benefits of using this non return damper?

A: Besides high reverse flow prevention efficiency, the damper offers corrosion and leak resistance, adjustable blades, and reliable operation across a broad temperature and pressure range, ensuring long-lasting and cost-effective system performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Volume Control Damper Category

MS Collar Dampers

Material : Mild Steel (MS)

Shape : Round

Condition : New

Feature : Robust air flow control and sealing

Construction : Other, Flanged collar design, powder coated finish

Temperature Range : Up to 80C

Volume Control Damper

Material : Metal; typically Aluminum or Galvanized Steel

Shape : Rectangular

Condition : New

Feature : Adjustable blades for airflow control

Construction : Other, Galvanized Steel

Temperature Range : 20C to 80C

Low Leakage Duct Damper

Material : Galvanized Steel / Mild Steel / Aluminium

Shape : Rectangular / Circular

Condition : New

Feature : Low leakage, pressure resistant, high durability, reliable air control

Construction : Other, Robust welded or riveted construction

Temperature Range : 10C to 80C

Back Draft Dampers

Material : Metal

Shape : Round

Condition : New

Feature : Prevents Backward Airflow

Construction : Galvanized Steel, Other

Temperature Range : Up to 60C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS