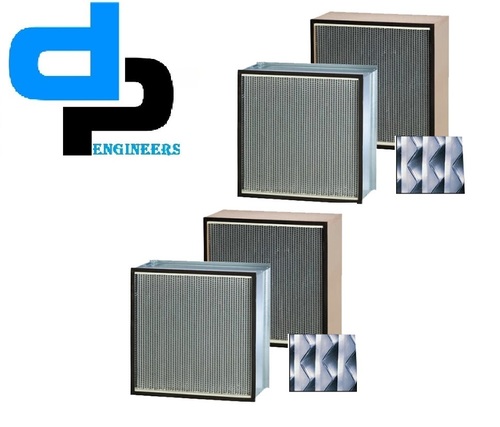

Industrial HEPA Filters

Industrial HEPA Filters Specification

- Temperature Range

- up to 80C

- Filter Type

- Panel Filter

- Flow Rate

- 1000-2000 m/h (varies by model)

- Pressure

- 250 Pa

- Cleaning Method

- Non-Washable, Replaceable

- Media Type

- Microfiber Glass

- Filtration Grade

- HEPA

- Connecting Type

- Flange/Flexible Gasket

- Capacity

- High Volume Dust Filtration

- Efficiency (%)

- 99.97% at 0.3 micron

- Condition

- New

- Material

- Aluminum Frame, Microfiber Glass Media

- Mesh

- Stainless Steel Mesh Support

- Diameter

- Standard/customized sizes

- Construction

- Box Type/Panel Type

- Medium Filter

- Glass Fiber Paper

- Weight

- 7-10 kg (varies by dimensions)

- Shape

- Rectangular

- Feature

- High Dust Holding Capacity

Industrial HEPA Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Industrial HEPA Filters

Our company is a reckoned trader, manufacturer, exporter and supplier of massively reckoned Industrial HEPA Filters. In order to provide rigidity & uniform air flow, these are made in accordance with defined norms of the arena. Thus, these are hugely in demand.

We manufacture and supply a wide range of Industrial HEPA Filters which has high filtration efficiency. These are manufactured by hemmed edges of aluminum separators in order to provide rigidity & uniform air flow. We do quality analysis and testing of these Industrial HEPA Filters before we handover this to our valuable clients. We have specialized team of experts who do quality checking under certain parameters that meets international standards.

salient Features

- Offered Industrial HEPA Filters are made by specialized team of experts.

- Our experts do quality checking under certain parameters, which suit international standards and norms.

Other details are as follows:

- Aluminum, S.S and G.I is used to make the body of HEPA filter.

- Used in aerospace, biomedical purpose, vacuum cleaners, nuclear industry, nuclear power, pharmaceutical processing, health care, hospitals, nuclear fuels, and electronic micro circuitry (computer chips).

Superior Filtration Performance

Engineered for critical environments, these HEPA panel filters achieve an efficiency of 99.97% for particles as small as 0.3 microns. Supported by a robust aluminum frame and stainless steel mesh, they combine durability with excellent particulate removal, making them ideal for industrial, medical, pharmaceutical, and laboratory applications.

Flexible Design and Easy Installation

Offered in standard and customizable sizes, our HEPA filters can be tailored for various ceiling or wall mounting requirements. The use of polyurethane sealant and high-quality gaskets (EVA/neoprene) ensures airtight integration in HVAC and clean room systems, preventing leaks and enhancing indoor air quality.

Optimized For Demanding Environments

With maximum humidity tolerance (100% RH), temperature resistance up to 80C, and high dust-holding capacity, these filters are dependable even under challenging operational settings. Aluminum/plastic corner guards protect filter edges during transport and installation, prolonging service life in busy industrial conditions.

FAQs of Industrial HEPA Filters:

Q: How are these industrial HEPA filters installed in clean rooms or HVAC systems?

A: The HEPA filters are designed for ceiling or wall mounting, using flange or flexible gasket connections for a secure fit. Installation is straightforward, with pre-configured sizes (610x610x150 mm, 610x305x150 mm) or custom dimensions available to suit different ductwork or modular filter housings commonly used in clean rooms and HVAC systems.Q: What materials are used for the filter media and frame, and why are they suitable for industrial environments?

A: The filters incorporate a robust aluminum frame and microfiber glass (glass fiber paper) as the primary filter media, supported by a stainless steel mesh. This combination offers high strength, corrosion resistance, and compatibility with stringent air quality requirements found in hospitals, labs, and pharmaceutical settings.Q: When should these HEPA filters be replaced, and how do I know it is time for a new one?

A: The filters are non-washable and should be replaced when the differential pressure across the filter exceeds the recommended limit (250 Pa) or if air quality drops. Regular monitoring of resistance or scheduled maintenance based on environment and usage conditions will help determine the optimal replacement interval.Q: Where can these HEPA filters be used effectively?

A: These filters are suitable for installation in industrial clean rooms, hospitals, pharmaceutical manufacturing, laboratories, and HVAC systems requiring high-efficiency air purification. Their high dust-holding capacity and reliability make them an optimal choice for any application needing strict particulate control.Q: What is the process for customizing filter size and specifications?

A: Customers can request custom dimensions, filter thickness, or additional features such as edge protection or special mounting accessories by providing their requirements during order placement. As an exporter, manufacturer, and supplier in India, we support tailored solutions to match specific project needs.Q: How do these HEPA filters benefit air quality management in sensitive environments?

A: By capturing 99.97% of airborne particles at 0.3 microns, these filters significantly reduce contaminants, ensuring stringent air purity standards in sensitive and critical operations. Their high dust capacity and efficient sealing mechanism prevent leakage, promoting a healthier and safer work environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HEPA Filters Category

Absolute Compact Filters

Price 4500 INR / Piece

Minimum Order Quantity : 10 Pieces

Filtration Grade : Other, HEPA/ULPA (as per design)

Construction : Other, Deeppleat design with robust frame

Medium Filter : Other, Air & Liquid

Condition : New

Deep Pleat HEPA Filter

Price 5000 INR / Piece

Minimum Order Quantity : 10 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Mini Pleat HEPA FILTER in Lucknow

Price 7800 INR / Piece

Minimum Order Quantity : 12 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Condition : New

0.3 Aluminium HEPA Filter

Price 4500 INR / Piece

Minimum Order Quantity : 10 Pieces

Filtration Grade : Hepa Filter

Construction : Box Filter

Medium Filter : Fiber Glass

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free