Industrial Filters for Pharmaceutical Industries

Industrial Filters for Pharmaceutical Industries Specification

- Connecting Type

- Clamp, Flange, Threaded

- Filtration Grade

- Fine/Absolute

- Flow Rate

- 20-2000 LPH (Liter/Hour)

- Temperature Range

- -10C to 120C

- Filter Type

- Cartridge/Panel/Disc/Inline

- Capacity

- As Required (Customizable)

- Media Type

- SS Mesh, Cloth, Pleated Paper

- Efficiency (%)

- Up to 99.9%

- Pressure

- Up to 16 bar

- Cleaning Method

- Manual/Backwash/Replaceable

- Condition

- New

- Material

- Stainless Steel

- Mesh

- 50 to 500 Micron options available

- Diameter

- Up to 600 mm

- Construction

- Welded/Seamless, Rigid Frame

- Medium Filter

- Liquid & Air

- Weight

- Customizable as per size

- Shape

- Round / Cylindrical

- Feature

- High Durable, Corrosion Resistant, Precision Filtration, Easy Installation, Seamless Finish

Industrial Filters for Pharmaceutical Industries Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Industrial Filters for Pharmaceutical Industries

Industrial Filters for Pharmaceutical Industries

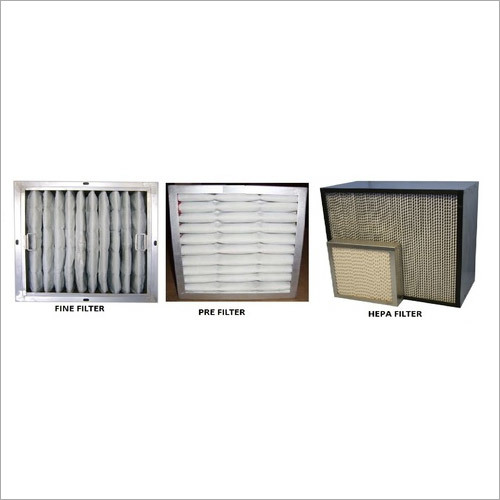

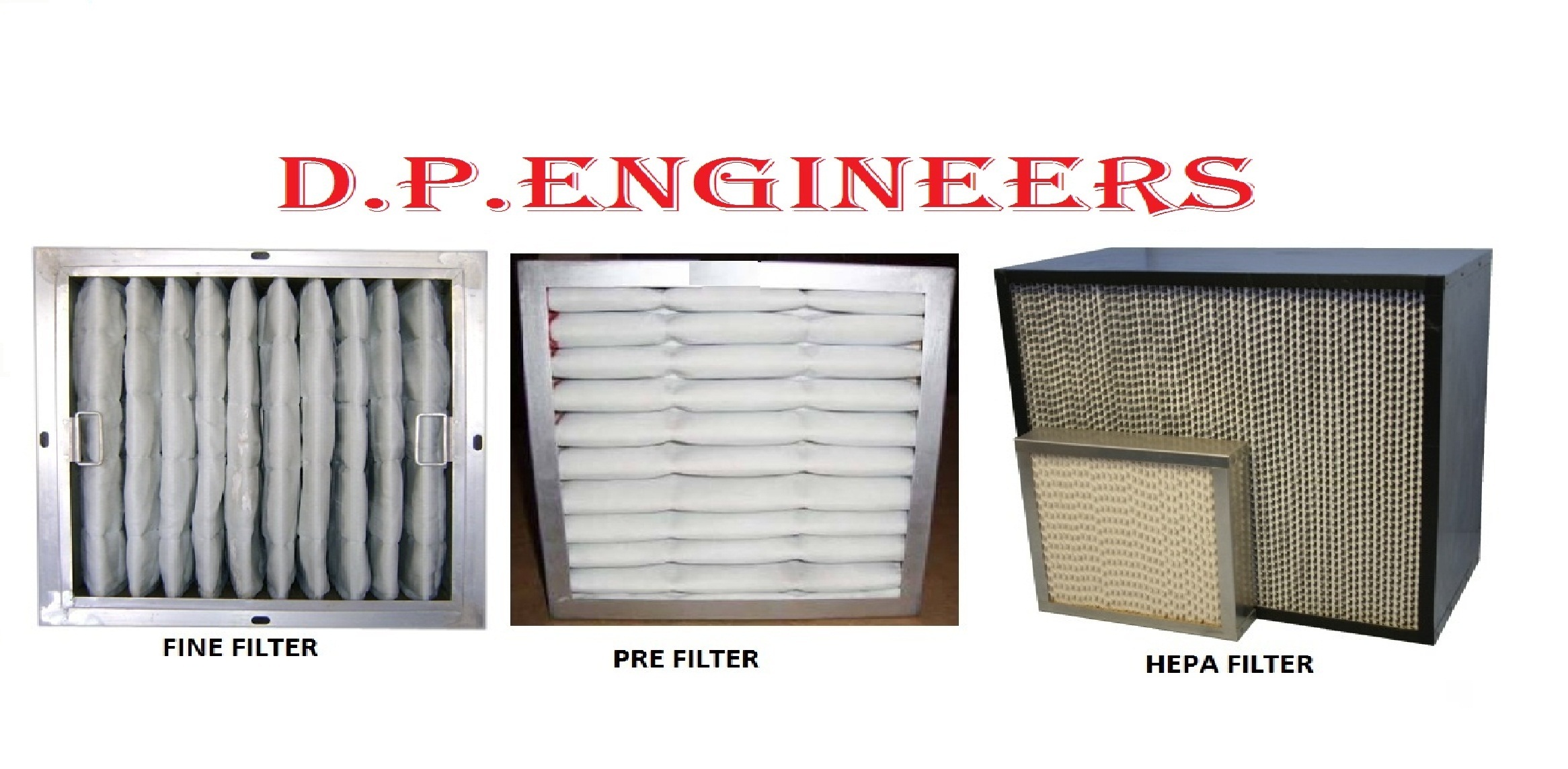

Following are some of the Industrial Filters for Pharmaceutical Industries:

- Microwave Filters

- Pre Filters

- Automotive HDPE Filters

- Fine Filter

- HEPA Filter

- Mini Plate Hepa Filter

- Ulpa Cells Filters

- Super Fine Filters

- High Temperature HEPA Air Filter

- Absolute Compact Filter

- HEPA FILTERS (Standard Flow)

- HEPA Filter Terminal Box

- High Efficiency Particulate Air Filter

- ULPA Filters

- Deep Pleat HEPA Filters

- Semi HEPA Filter

- Air HEPA Filters

- Industrial HEPA Filters

Precision and Versatility in Filtration

Our pharmaceutical filters are designed to meet the stringent demands of pharmaceutical processes, including sterile environments and injection production. With a broad micron rating range (0.5100), our filters provide both fine and absolute filtration grades, accommodating both liquid and air mediums. Customizable shapes, sizes, and filtration media ensure compatibility with numerous process requirements.

Enhanced Durability and Effortless Maintenance

Constructed with high-grade stainless steel and featuring corrosion-resistant finishes like mirror polish and electropolishing, our filters offer long operational life (618 months) and require minimal maintenance. Tool-free disassembly allows for quick cleaning and replacement, contributing to lower downtime and improved productivity in pharmaceutical operations.

FAQs of Industrial Filters for Pharmaceutical Industries:

Q: How do industrial filters benefit pharmaceutical manufacturing processes?

A: Industrial filters ensure precision removal of contaminants, supporting critical applications such as sterile filtration, injection manufacturing, and CIP systems. This guarantees product safety, compliance with industry standards, and extends equipment lifespan through corrosion-resistant and durable components.Q: What are the available end connection options for these filters?

A: Our industrial filters come with BSP, NPT, and DIN standard end connection options, as well as clamp, flange, and threaded connecting types, ensuring easy integration with various pharmaceutical pipelines and equipment.Q: When should I replace or clean these filters, and what is the maintenance process?

A: Typically, filters have an operating life of 618 months, depending on the specific process and usage conditions. Maintenance is low, with tool-free disassembly for manual cleaning, backwash, or complete replacement as required, ensuring minimal disruption to production schedules.Q: What customization options are available for specialized pharmaceutical processes?

A: Filters can be customized in terms of diameter (up to 600 mm), mesh size (50500 micron), filter type (cartridge, panel, disc, inline), flow rates (202000 LPH), and capacities as needed. Designs can also be tailored according to provided drawings or specific process requirements.Q: Where are these pharmaceutical industrial filters manufactured and supplied from?

A: These filters are manufactured, exported, and supplied from India by reliable manufacturers, ensuring global standards of quality and timely fulfillment for pharmaceutical industry clients.Q: What are the key features that set these industrial filters apart?

A: Key features include high durability, corrosion resistance, precision filtration up to 99.9% efficiency, easy installation, seamless construction, customizable design, and compatibility with a range of operating pressures and temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filters-Manufacturers,Suppliers & Exporters in Category

Channel Type Pre Filters

Minimum Order Quantity : 1 Piece

Material : Stainless Steel / Aluminum

Construction : Other, Channel type welded frame

Feature : Superior oil, dust, and dirt filtration

Condition : New

Filtration Grade : Other, Prefilter

Panel Microvee Filter

Material : Galvanized Iron / Aluminium Frame, Synthetic Nonwoven Media

Construction : Other, Panel type, Rigid construction

Feature : High dust holding capacity, Low resistance, Rigid and lightweight design

Condition : New

Filtration Grade : Other, Medium

COMBINATION FILTER

Material : Mild Steel

Construction : Other, Welded/Seamless

Feature : Compact design, dualstage filtration, easy installation

Condition : New

Filtration Grade : Other, Medium to Fine

AHU PRE Filters From Pardi Valsad Gujarat India

Minimum Order Quantity : 12 Pieces

Material : Galvanised steel/CRCA Powder Coated/Aluminum Anodized/SS304

Construction : Box Filter

Feature : pharmaceutical,Hotel,Malls,Hospital, OT

Condition : New

Filtration Grade : Pre Filter

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS