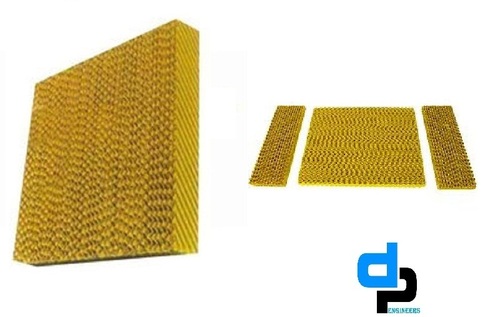

Honey Comb Pads

MOQ : 300 Square Foots

Honey Comb Pads Specification

- Application

- Evaporative Air Coolers, HVAC Systems

- Material

- Cellulose Paper with Anti-fungal Coating

- Air Flow

- Optimized for Uniform Air Distribution

- Condition

- New

- Type

- Evaporative Cooling Pad

- Dimension (L*W*H)

- Customizable as per Cooler Design

- Cooling Type

- Evaporative

- Water Flowing Rate

- Consistent Water Retention

- Noise Control

- Silent Operation

Honey Comb Pads Trade Information

- Minimum Order Quantity

- 300 Square Foots

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Available

- Yes

- Main Export Market(s)

- Eastern Europe, Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Andaman and Nicobar Islands, Nagaland, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Himachal Pradesh, Jammu and Kashmir, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, All India, Uttarakhand, Daman and Diu, Lakshadweep, Haryana, Kerala, Central India, Odisha, Jharkhand, West India, Chhattisgarh

About Honey Comb Pads

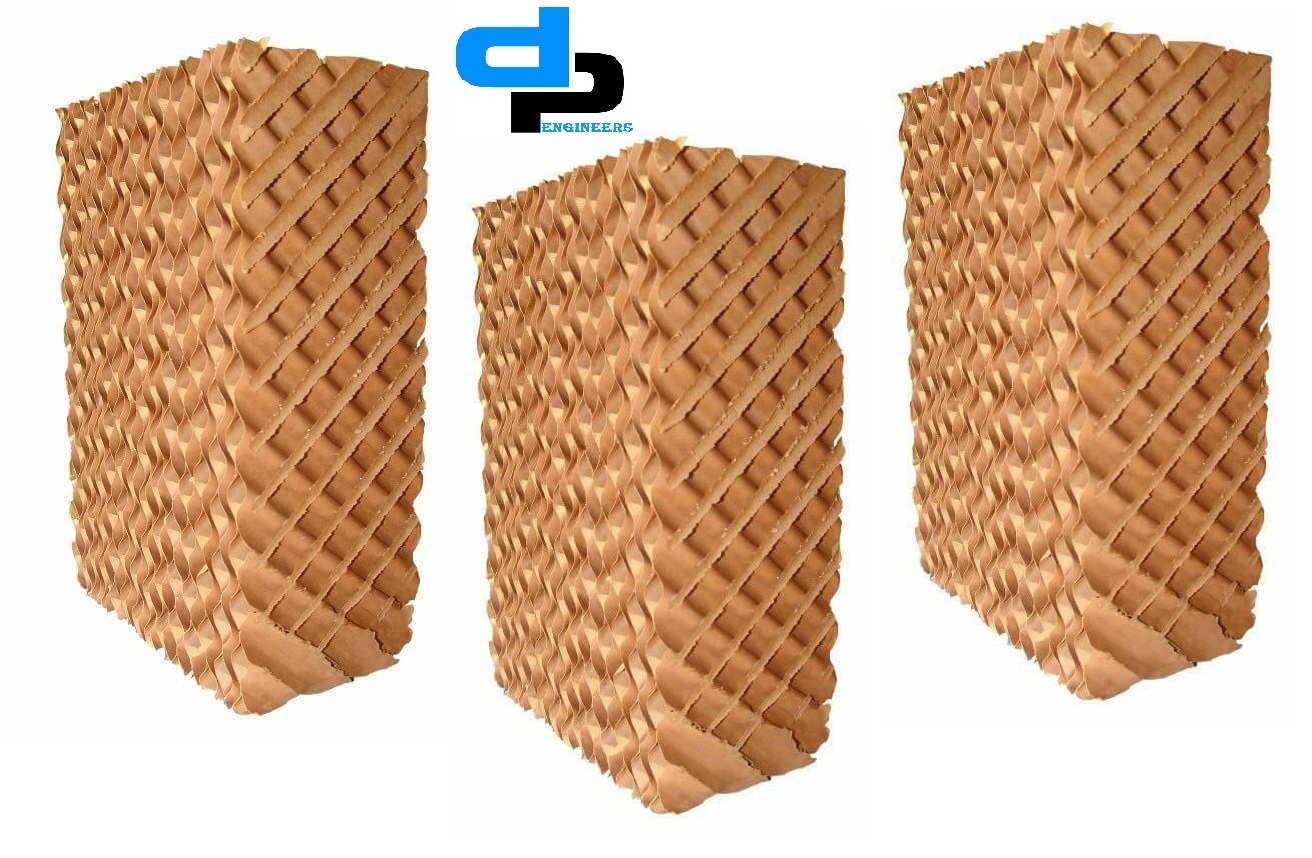

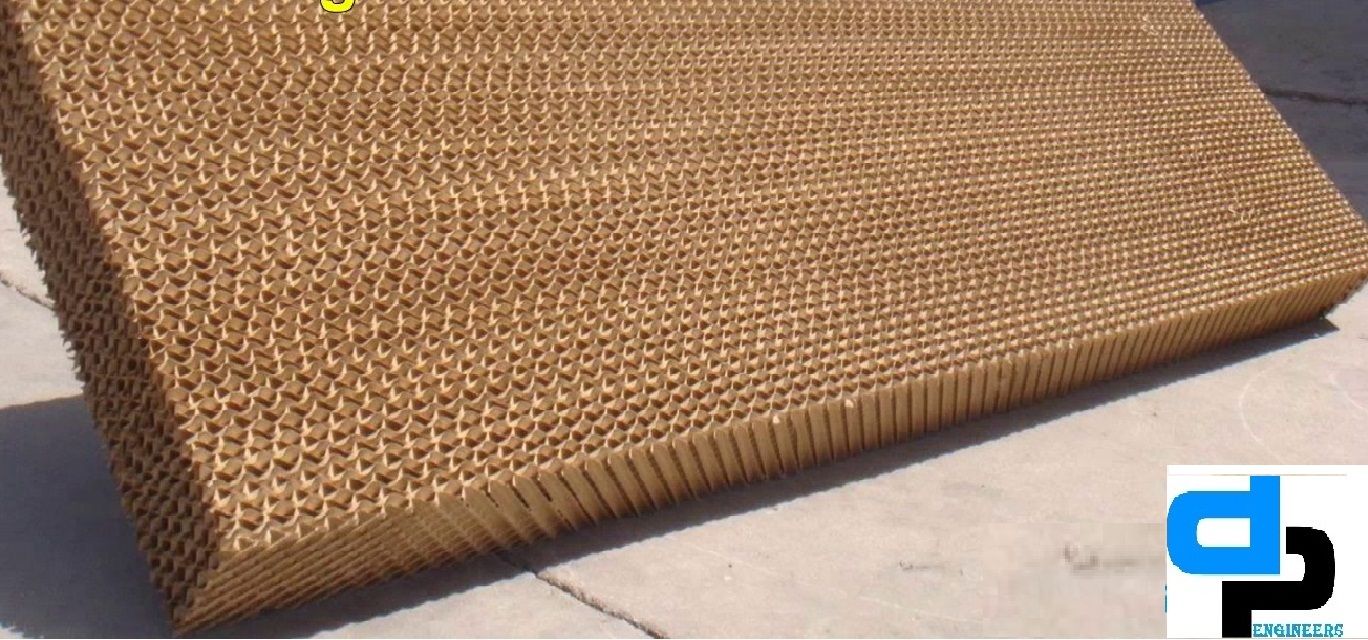

Honey Comb PadsWe are involve in offering superior quality Honey Comb Pads. These Honey Comb are made from high quality of raw material which ensure durability at its user end. These products are available in market at most economical rates. The unique design allows for a low pressure drop across the pad whilst achieving a high cooling efficiency. The pad is designed to be self-cleaning and will retain its rigid structure when exposed to water making it extremely durable. Our pads are able to achieve exceptional wetting abilities to allow for optimal cooling effect in the most economic and environmentally friendly way.

Applications:

| Residential | Buildings | Schools & institutes |

| Auditoriums | Banquet halls | Poultry farms |

| Shopping plazas | Hotel | Kitchens |

| Generator rooms | Pharmaceutical plants | Food processing units |

| Banks | Offices | Canteens |

| Temples | Hospitals | Bakeries |

| Factories | Restaurants |

Show rooms

|

| Live stocks | Green houses |

Superior Evaporation Efficiency

Delivering over 80% evaporation efficiency, our Honey Comb Pads offer robust cooling capability for evaporative air coolers and HVAC setups. The material composition, including high-quality cellulose paper treated with anti-fungal and antibacterial properties, ensures uniform air distribution and consistent water retention for enhanced comfort.

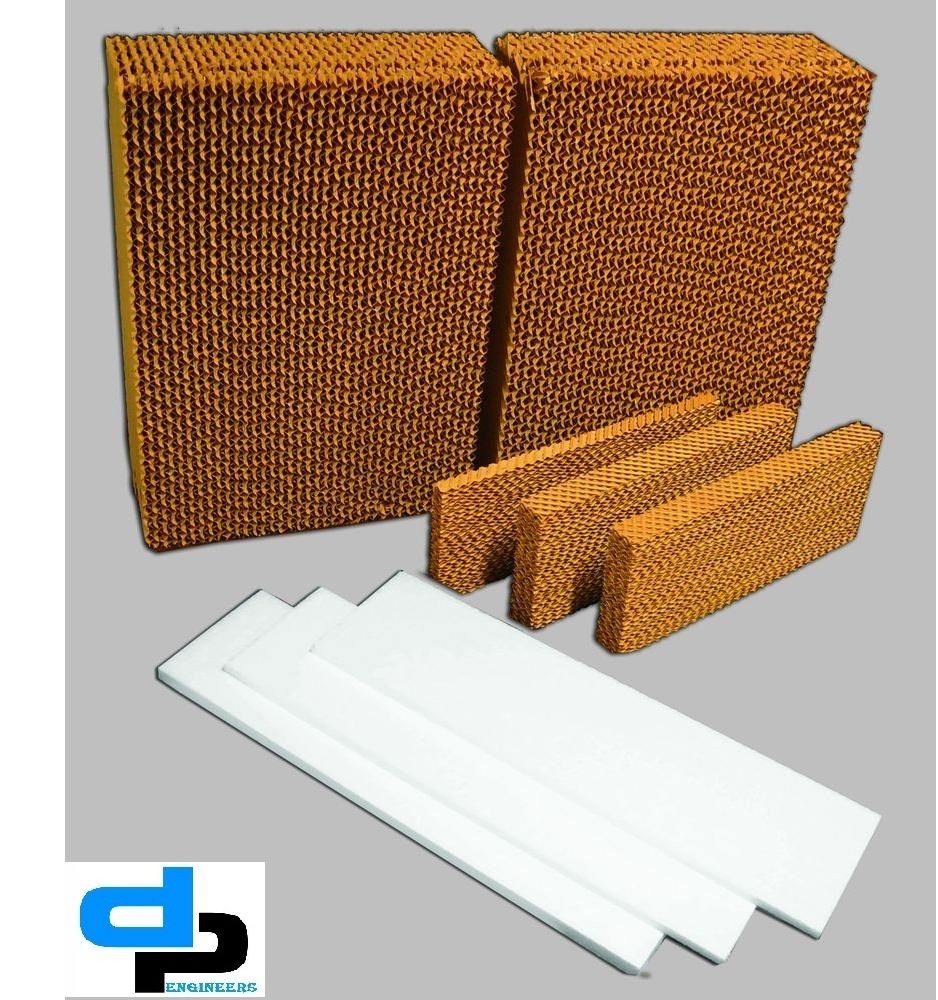

Customizable and Durable Design

Available in brown and green, with thickness options between 50mm and 200mm, our pads can be tailored to fit your specific cooler design. Reinforced edges with optional plastic or aluminum frames safeguard against damage and extend pad lifespan. Customers can choose panel or brick-type shapes according to application needs.

Low Maintenance and Safe Operation

Routine cleaning is all thats required to keep the pads functioning optimally. With fire retardant treatments and silent operation, they provide not only safety but also a noise-free environment. Anti-bacterial and odor control features contribute to healthy air quality for occupied spaces.

FAQs of Honey Comb Pads:

Q: How do Honey Comb Pads improve air cooling in evaporative systems?

A: Honey Comb Pads leverage a highly absorbent cellulose structure coated with anti-fungal agents to maximize evaporation, promoting cooler air flow and greater distribution efficiency. Proper placement enhances overall system performance in air coolers and HVAC units.Q: What is the process for installing and replacing these cooling pads?

A: Installation is straightforward due to customizable sizing and reinforced edges; users simply fit the pad into their cooling equipment, securing any frame if needed. Replacement is equally hassle-free, typically matching the existing dimensions for seamless integration.Q: When should the Honey Comb Pads be replaced for optimal cooling?

A: With a lifespan of 13 years depending on usage, its advisable to inspect pads annually and replace them when signs of wear, reduced absorption, or diminished cooling are noticed, ensuring continuous performance and hygiene.Q: Where can these Honey Comb Pads be utilized apart from air coolers?

A: Besides evaporative air coolers, the pads are well-suited for HVAC system installations in residential, commercial, and industrial environments, offering flexible cooling solutions across various climate control applications.Q: What benefits do the flame resistance and edge protection offer?

A: Fire-retardant treatments reduce fire risk, while reinforced edges with plastic or aluminum frames help prevent damage during handling and extend the pads functional life, assuring safe usage in high-demand environments.Q: How does the Honey Comb Pad contribute to odor control and air hygiene?

A: Equipped with antibacterial properties and effective odor control, the pad provides cleaner air by minimizing microbial growth and unwanted smells, contributing to healthier living and working spaces.Q: What maintenance is required for prolonged pad efficiency?

A: Low maintenance is a key advantage; periodic cleaning removes dust and buildup, preventing blockages and maintaining airflow and water absorption rates. No complex procedures are necessary, ensuring ongoing pad performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Evaporative Cooling Pad Category

Rigid Cell High Efficiency Cooling Pad

Price 300.00 INR

Minimum Order Quantity : 1 Piece

Type : Industrial Air Washer Unit

Condition : New

Application : Industrial Air Washer Unit

Evaporative Cooling Pad

Material : Other , Cellulose Paper with Special Organic Resins

Type : Evaporative Cooling Pad

Condition : New

Application : Greenhouses, Poultry Farms, Industrial Sheds, Cooling Units

1800 X 600 X 200 Mm Air Cooling Pad

Price 600 INR / Square Foot

Minimum Order Quantity : 200 Square Foots

Material : Other

Yellow Cooling Pad

Price 300 INR / Square Foot

Minimum Order Quantity : 200 Square Foots

Material : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS