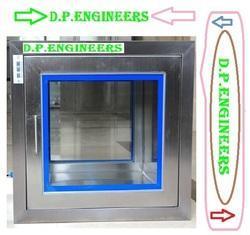

Dynamic Pass Box

Dynamic Pass Box Specification

- Feature

- UV Lamp, Door Interlocking System, Indicator Lights

- Filter Type

- HEPA and Pre-Filters

- Application

- Pharmaceutical, Clean Room, Laboratory, Hospitals

- Nozzle

- Stainless Steel Rounded Corners Nozzle

- Lighting

- LED Light Inside

- Type

- Dynamic Pass Box

- Power Consumption

- 40 W 130 W

- Floor

- Stainless Steel / Smooth Finish

- Condition

- New

- Weight

- Approx. 70 kg 110 kg

- Thickness

- 1.2 mm to 1.5 mm

- Voltage

- 220 V / 230 V AC, 50 Hz

- Frame Material

- Stainless Steel

- Door

- Electromagnetic Interlocking Doors

- Dimension (L*W*H)

- 600 x 600 x 600 mm / 900 x 900 x 900 mm / Custom

- Filters

- HEPA Filter (0.3 micron), Pre Filter (10 micron)

- Air Flow

- Horizontal / Vertical

- Material

- Stainless Steel 304 / 316

- Air Volume

- 250 450 CFM

- Construction

- Double-walled construction

- Door Indicator

- Provided for operational safety

- Electrical Safety

- Earth protection provided

- Accessories

- User Manual, Test Certificate

- Display

- Digital Display (optional)

- UV Lamp

- Available for surface disinfection

- Operation

- Microprocessor-based control system

- Static Pressure

- >30 mm of WC

- Noise Level

- <65 dB

- Material Finish

- Matt / Mirror Finish

- Alarm System

- Audio-Visual Alarm for door status

- Installation

- Floor Mounted / Wall Mounted

About Dynamic Pass Box

Technical Specifications:

Supply Filter:

- Filter Casing Aluminum Factory extruded section.

- Efficiency 99.999% down to 0.001 micron { EU 14 rating.}

- Madia Micro fiberglass paper media {Imported } Pleated along with hot Melt Glue.

- Material of construction: - S.S.304 / 316 PVC coated matt finish OR CRCA Powder Coated with RAL 9004 Color Shade.

Suction Filter:

- Filter Casing S.S304 / 316 Flange Type.

- Efficiency 95% down to 5 micron { EU 4 rating.}

- Madia Non Woven Synthetic Media sandwiched between two layers of High Density Polyethylene Mesh.

Blower motor assembly:

DP ENGINEERS Make, 230Volts, 50Hz, Single- Phase imported Blower along with inbuilt motor

Electrical details:

- 8/20w, Fluorescent light with milky diffuser.

- 8/15w, UV light along with Hour Meter.

- 12 Volt, Electromagnet for door interlocking.

- 12 Volt, Buzzer.

- 12 Volt Indicator lamps.

- 16 Amps. Three pin top along with connection cable

Accessories:

- Hour Meter Connected to UB Light.

Door Handles:

- Magnehelic/Minihelic Pressure Gauge.

Advanced Operational Control for Cleanroom Safety

The Dynamic Pass Box integrates a microprocessor-based control system and electromagnetic interlocking doors with audio-visual alarms, ensuring operational safety and contamination control. Its user-friendly digital display (optional) and indicator lights make the system intuitive to monitor and operate. The door interlocking system prevents accidental cross-contamination, supporting stringent cleanroom protocols.

Superior Construction and Surface Disinfection

Constructed with SS 304 or 316 stainless steel and a double-walled frame, the pass box offers durability and secure material transfer. An integrated UV lamp enables effective surface disinfection prior to transfer, reducing the risk of microbiological contamination. Its smooth, matt or mirror finish facilitates easy cleaning and maintenance, further supporting hygienic operations.

FAQs of Dynamic Pass Box:

Q: How does the UV lamp in the Dynamic Pass Box enhance surface disinfection?

A: The UV lamp emits UV-C light, which effectively destroys bacteria, viruses, and other microorganisms on surfaces inside the pass box, ensuring materials entering or exiting the controlled area are decontaminated before transfer.Q: What safety features are provided for operational security?

A: Safety is ensured through electromagnetic interlocking doors, audio-visual alarms for door status, a door indicator, earth protection for electrical safety, and a robust double-walled construction that maintains cleanroom standards.Q: When should the Dynamic Pass Box be used in pharmaceutical or laboratory environments?

A: Use the pass box whenever materials need to be transferred between cleanroom zones to prevent cross-contamination, particularly during active production or sensitive research operations.Q: Where can the Dynamic Pass Box be installed?

A: This equipment can be floor or wall mounted based on facility requirements, making it suitable for pharmaceutical, hospital, laboratory, and cleanroom installations.Q: What is the process for material transfer using this pass box?

A: Materials are placed inside the pass box; the UV lamp can be activated for disinfection. The microprocessor controls door interlocking, allowing only one door to open at a time, while indicator lights and alarms guide safe operation.Q: What are the main benefits of using this pass box in cleanroom settings?

A: The pass box provides rapid surface disinfection, improves workflow safety, minimizes contamination risk, and ensures reliable operation with advanced control and alarm systems.Q: How does the filtration system ensure clean air within the pass box?

A: Equipped with HEPA (0.3 micron) and pre-filters (10 micron), the pass box maintains a high level of air purity by filtering out particulates and contaminants during material transfer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Clean Room Equipments Category

Horizontal Laminar Flow Cabinet

Application : Laboratory, Pharmaceutical, Electronics Assembly

Filter Type : Other, HEPA 99.99% Efficiency

Feature : UV Germicidal Lamp, Low Noise Operation

Condition : Other, New

Type : Other , Horizontal Laminar Flow Cabinet

Frame Material : Stainless Steel

Fluid Bed Dryer Bags

Application : Industrial Drying

Filter Type : Fabric, Other

Feature : Efficient drying reusable bags

Condition : Other, New

Type : Fluid Bed Dryer Bags, Other

Frame Material : Stainless Steel

Interlocking Pass Box

Application : Clean Room Equipment

Filter Type : HEPA, Other

Feature : Prevent contamination between clean and unclean areas

Condition : New, Other

Type : Other , Interlocking Pass Box

Frame Material : Stainless Steel

Pass Box

Application : Used for transferring materials into cleanrooms without contamination

Filter Type : Other, HEPA filters

Feature : Pass Box Stainless Steel UV Lamp option

Condition : Other, New

Type : Other , Static Pass Box

Frame Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free