Dwyer USA DM-1102 DigiMag Differential Pressure Gauge

Dwyer USA DM-1102 DigiMag Differential Pressure Gauge Specification

- Display

- Digital, LCD

- Sensor Type

- Piezo-resistive

- Outer Size

- 4.13 x 4.13 x 2.15 (105 x 105 x 54.5 mm)

- Grade

- Industrial

- Bourdon Tube

- None (Solid-state sensing)

- Thread

- 1/8 NPT female

- Seal Material

- Silicone

- Material

- ABS plastic housing

- Dial Material

- Not applicable (Digital)

- Pointer Material

- Not applicable (Digital)

- Processing Type

- Electronic/Digital

- Diameter

- 4.13 (face)

- Glass Size

- Not applicable (LCD Display)

- Mount Type

- Panel or surface mount

- Scale Range

- 0-2 w.c. (0-500 Pa, model dependent)

- Accuracy

- 1% of full scale

- Finishing

- Matte grey plastic

- Measure Pressure Of

- Air and compatible gases

- Accessories

- Mounting hardware, Instruction manual

Dwyer USA DM-1102 DigiMag Differential Pressure Gauge Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Central India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Bihar, Chhattisgarh, Delhi, Daman and Diu, Gujarat, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Chandigarh, Himachal Pradesh, Manipur, Arunachal Pradesh, Pondicherry, Uttarakhand, Lakshadweep, South India, Jharkhand, West India, All India

About Dwyer USA DM-1102 DigiMag Differential Pressure Gauge

DigiMag Differential Digital Pressure Gage,Range 0-0.25WC

The DigiMag Series DM-1000 Digital Differential Pressure and Flow Gages monitor the pressure of air and compatible gases just as its famous analog predecessor the Magnehelic Differential Pressure Gage. All models are factory calibrated to specific ranges. The 4-digit LCD can display readings in common English and metric units so conversions are not necessary. The simplified four button operation reduces set up time and simplifies calibration with its digital push button zero and span. The DigiMag Digital Gages are more versatile than analog gages with their ability to be field-programmed to select pressure, air velocity or flow operation depending on model. The DigiMag Digital Gages have an added feature for filter applications where a set point can be input where the display will blink when the filter is dirty, alerting the user that a maintenance action needs to occur. Programming the Series DM-1000 is easy using the menu key to access 4 simplified menus which provide access to, depending on model: security level; engineering units; K-factor for use with various Pitot tubes and flow sensors circular or rectangular duct size for volumetric flow operation; filter set point; view peak and valley process readings; digital damping for smoothing erratic process applications; display update to conserve battery life; zero and span field calibration. The Series DM-1000 DigiMag Digital Differential Pressure and Air Flow Gages possess a full-scale accuracy of 1% on ranges down to 2 in H2O and 2% accuracy down to the very low range of 1 inch to 0.25 in H2O. DigiMag Digital Differential Pressure Gages offer power versatility by working with 9-24 VDC line power or simply 9V battery power. If using line power and connecting the 9V battery, the battery will act as a back-up if line power is lost or interrupted.

Precise Differential Pressure Measurement

Utilizing piezo-resistive sensing technology, the DM-1102 provides accurate differential pressure readings for air and compatible gases. Its scale ranges up to 2 w.c. or 500 Pa (depending on model), ensuring suitability for HVAC, clean rooms, and industrial process applications. The digital LCD display allows for clear and fast data retrieval, supporting efficient decision-making.

User-Friendly Interface and Installation

This gauge offers easy zero adjustment with a single push-button and a rapid response time of less than one second. Whether installed in a panel or mounted on a surface, its lightweight, compact design, and included mounting hardware simplify both initial setup and ongoing operation, promoting convenience in various environments.

Reliable Performance for Harsh Conditions

Designed for industrial environments, the DM-1102 boasts an IP65-rated front panel, ensuring protection against dust and splashes. The device operates reliably across a wide temperature range (-20C to 70C), making it ideal for diverse climate zones. Optional backlight models improve readability in low-light conditions, optimizing safety and workflow.

FAQs of Dwyer USA DM-1102 DigiMag Differential Pressure Gauge:

Q: How is the Dwyer DM-1102 Differential Pressure Gauge powered?

A: The DM-1102 can be powered using a 9-24 VDC supply or a 9 V battery, providing flexibility for both permanent installations and portable applications.Q: What gases can the DM-1102 measure pressure for?

A: This gauge is designed specifically to measure air and compatible non-corrosive gases, making it suitable for HVAC, clean room, and laboratory use.Q: When should I use the analog output feature of the DM-1102?

A: The analog output (4-20 mA or 0-10 V) is beneficial when you need to interface the gauge with external monitoring or control systems for real-time process integration.Q: Where is the optimal place to install the DM-1102 gauge?

A: It can be mounted on panels or flat surfaces in areas requiring differential pressure monitoring, such as process control rooms, air-handling units, or laboratory environments.Q: What is the process for adjusting the zero point on this device?

A: Zero adjustment is straightforward; simply press the push-button zero to recalibrate the gauge, ensuring accurate baseline measurements in changing environments.Q: Can the DM-1102 handle overpressure situations safely?

A: Yes, the gauge has an overpressure limit of twice its full scale, protecting the unit from accidental pressure spikes during operation.Q: How does using the DM-1102 benefit industrial applications?

A: The DM-1102 offers fast, accurate readings with electronic processing and a robust, dust-resistant enclosure, helping optimize system efficiency, ensure safety, and maintain regulatory compliance in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DM-1000 Digital Differential Pressure Category

Dwyer USA DM-1103 DigiMag Digital Pressure Gauge

Measure Pressure Of : Other, Air and Compatible Gases

Outer Size : 4 inches (case diameter)

Material : Other, ABS Plastic and Polycarbonate Front

Sensor Type : Differential Pressure Sensor

Accessories : Manual, Mounting Bracket, Batteries

Display : 4digit LCD Digital Display

DWYER DM-1104 DIGIMAG DIFFERENTIAL PRESSURE GAUGE

Measure Pressure Of : Other, Air and noncorrosive gases

Outer Size : 96 96 mm

Material : Other, Polycarbonate housing and ABS front

Sensor Type : Electronic Differential Pressure Sensor

Accessories : Mounting bracket, installation manual

Display : Digital LCD

Dwyer USA DM-1110 Digi Mag Digital Pressure Gage With Range of 0 to 25 in w.c

Measure Pressure Of : Other, Air and Noncorrosive Gases

Outer Size : 4.7 x 4.13 x 1.94 (120 mm x 105 mm x 49 mm)

Material : Other, ABS Plastic Housing

Sensor Type : Differential Pressure Sensor

Accessories : Mounting Bracket, Instruction Manual

Display : Digital LCD

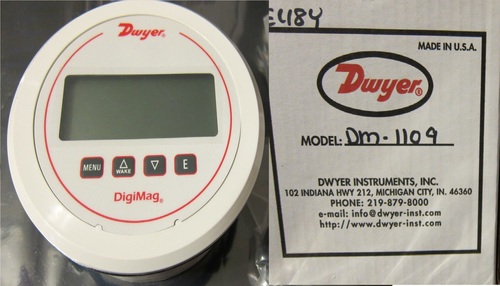

Dwyer USA DM-1109 DigiMag Digital Pressure Gauge

Measure Pressure Of : Other, Air, Noncorrosive Gas

Outer Size : 76 mm x 92 mm x 38 mm (H x W x D)

Material : Other, ABS Plastic Body, Stainless Steel Fittings

Sensor Type : Digital Pressure Sensor

Accessories : Mounting bracket, rubber boot

Display : 4Digit LCD

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS