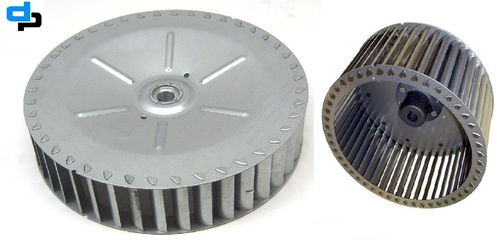

DIDW Centrifugal Fan 530 MM X 455 MM

DIDW Centrifugal Fan 530 MM X 455 MM Specification

- Power

- 2.2 kW

- Motor Power

- 3 HP

- Flow Rate

- 3400-3700 m/h

- Pressure Range

- 320-400 Pa

- Life Span

- 10-12 Years

- Output Power

- 2.2 kW

- Max Pressure

- 410 Pa

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 3400 m/h

- Pressure

- 380 Pa

- Application

- HVAC systems, Industrial Ventilation, Exhaust, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- <85 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 52 kg

- Dimension (L*W*H)

- 530 mm x 455 mm x 510 mm

- Color

- Silver Grey

DIDW Centrifugal Fan 530 MM X 455 MM Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Mizoram, Sikkim, Meghalaya, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Maharashtra, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Tamil Nadu, Tripura, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Uttar Pradesh, West Bengal, Madhya Pradesh, Telangana, Central India, Himachal Pradesh, All India

About DIDW Centrifugal Fan 530 MM X 455 MM

DIDW Centrifugal Fan 530 MM X 455 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 62 | DP 21 18 | 530 X 455 X 430 | 21 X 18 | 35 MM,40 MM,& 1.5 | AL. / GI. |

Superior Construction and Durability

This centrifugal fan is built with dynamically balanced mild steel and features an epoxy coating for enhanced corrosion resistance, making it suitable for long-term use in harsh industrial conditions. The shielded ball bearings and robust design contribute to its impressive lifespan of 1012 years, ensuring reliable air movement and reduced maintenance needs.

Optimized Performance and Flexibility

With forward-curved blades and a double-width, double-inlet layout, the fan achieves high efficiency and uniform air flow. Its output power of 2.2 kW, combined with a 3 HP motor and belt drive system, allows for precise control of speed and airflow, making it adaptable to a wide range of applications from HVAC to exhaust and air handling units.

Safety and Quiet Operation

Operating at a noise level of less than 85 dB(A), the fan provides a quieter environment, crucial for industrial and commercial installations. Class F insulation and shielded bearings ensure electrical and mechanical safety, while epoxy coating protects against moisture and corrosion, further enhancing safety and reliability in critical applications.

FAQs of DIDW Centrifugal Fan 530 MM X 455 MM:

Q: How is the DIDW Centrifugal Fan 530 MM X 455 MM installed in industrial settings?

A: The fan is designed for floor or base mounting, making it easy to integrate into HVAC systems or industrial ventilation setups. Proper alignment of the belt drive and secure fastening ensure optimal operation and safety.Q: What benefits does the forward curved, double-width impeller provide?

A: A forward-curved, double-width impeller enhances airflow efficiency, promotes uniform distribution, and allows the fan to deliver higher volumes at lower noise levels, which is optimal for ventilation and exhaust applications.Q: When should this centrifugal fan be used in HVAC or industrial environments?

A: This fan is ideal for scenarios requiring robust airflow between 34003700 m/h, such as large-scale ventilation, exhaust extraction, and air handling units. It operates reliably across a temperature range of -10C to +60C.Q: Where can this centrifugal fan be implemented within a facility?

A: The units compact, floor-mounted design makes it suitable for installation in plant rooms, industrial workshops, commercial buildings, and areas requiring continuous air movement and exhaust functionality.Q: What process ensures the fans long lifespan and corrosion resistance?

A: The fan components are epoxy coated for corrosion resistance and employ dynamically balanced mild steel. Shielded ball bearings and Class F insulation further extend operational longevity, providing 1012 years of dependable service.Q: How does the belt drive system affect fan operation and maintenance?

A: The belt drive system enables precise speed control and helps minimize vibration, contributing to smoother operation and easier maintenance compared to direct-drive systems, ideal for industrial applications.Q: What are the main benefits of using this fan for industrial air handling?

A: Key benefits include high airflow capacity, reliable performance in variable conditions, low noise output, corrosion resistance, safety features, and a long operational life. These attributes help maintain efficient, safe, and comfortable workplace environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 230 MM X 178 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 100350 Pa

Application : Other, Ventilation, HVAC systems, Air Handling Units, Industrial Exhaust

Pressure : Other, Up to 350 Pa

Life Span : More than 20,000 hours

DIDW Centrifugal Fan 180 MM X 152 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : up to 300 Pa

Application : Other, Ventilation, Air Handling Units, HVAC Systems

Pressure : Other, 275 Pa

Life Span : 57 years

DIDW Centrifugal Fan 300 MM X 254 MM

Price 6000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 70130 mm WG

Application : Other, Industrial Ventilation, HVAC, Exhaust systems, Air handling units

Pressure : Other, 70130 mm WG

Life Span : 810 Years

DIDW Centrifugal Fan 280 MM X 280 MM

Price 4000 INR

Minimum Order Quantity : 5 Pieces

Pressure Range : 300 500 Pa

Application : Other, Industrial ventilation, Air handling units, HVAC systems, Exhaust and supply air systems

Pressure : Other, 450 Pa

Life Span : 10 Years (Approximate)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS