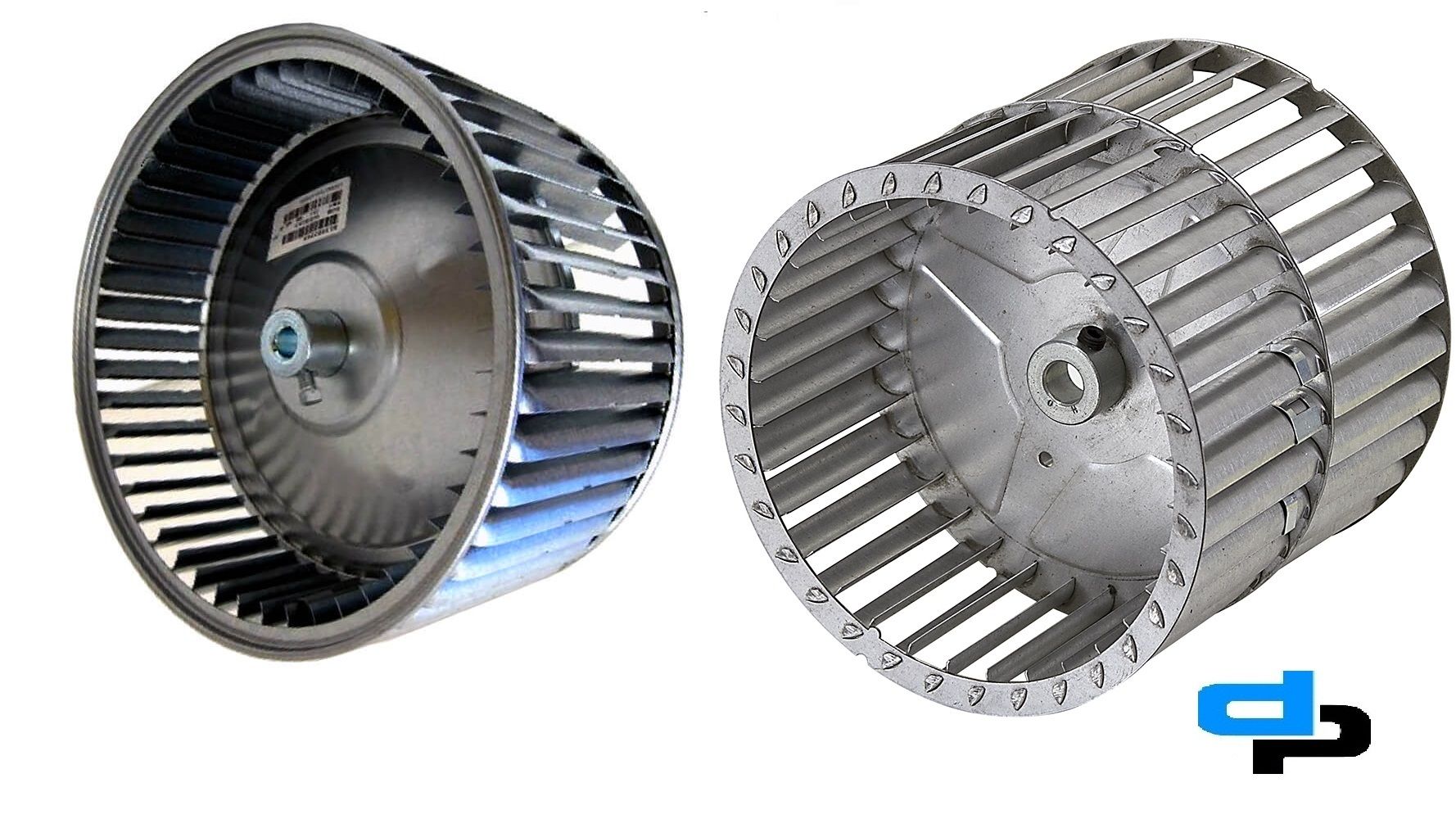

DIDW Centrifugal Fan 455 MM X 305 MM

MOQ : 2 Pieces

DIDW Centrifugal Fan 455 MM X 305 MM Specification

- Life Span

- 10-12 Years

- Power

- 3.0 kW

- Motor Power

- 3 HP

- Max Pressure

- 80 mm WG

- Pressure Range

- 40-80 mm WG

- Output Power

- 3 kW

- Flow Rate

- 4500-5000 m3/hr

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel / Galvanized Steel

- Capacity

- Up to 5000 CFM

- Pressure

- 40-80 mm WG

- Application

- HVAC, Industrial Ventilation

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- <80 dB

- Power Source

- Electric

- Voltage

- 380-415 V

- Weight

- Approx. 48 kg

- Dimension (L*W*H)

- 455 mm x 305 mm

- Color

- Blue / Gray

DIDW Centrifugal Fan 455 MM X 305 MM Trade Information

- Minimum Order Quantity

- 2 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Tripura, Meghalaya, All India, South India, Central India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Jharkhand

About DIDW Centrifugal Fan 455 MM X 305 MM

DIDW Centrifugal Fan 455 MM X 305 MM

DIDW CENTRIFUGAL BLOWER

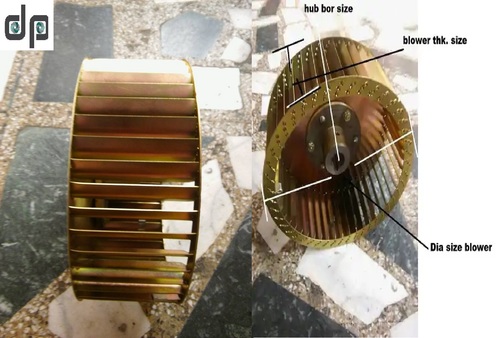

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 58 | DP 18 12 | 455 X 305 X 365 | 18 X 12 | 30 MM,35 MM,& 1.5 | AL. / GI. |

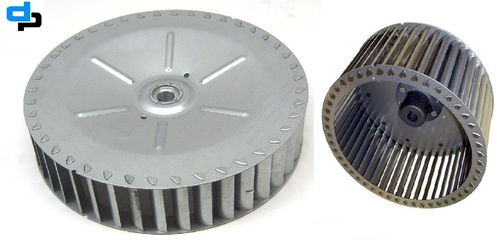

High Efficiency and Performance

Achieving static efficiency above 75%, the DIDW centrifugal fan ensures powerful air delivery with a flow rate of up to 5000 m/hr. Its backward curved impeller and belt-driven motor deliver stable, energy-efficient operation, making it ideal for heavy-duty industrial and HVAC applications where reliability and output matter.

Durable Construction and Longevity

Manufactured from high-quality mild steel or galvanized steel, this fan comes with a sealed ball bearing system and TEFC motor enclosure. These features minimize maintenance and extend the operational life to 10-12 years, providing peace of mind for plant managers and facility operators.

Quiet Operation and User Safety

With noise levels below 80 dB and a base-mounted, totally enclosed fan-cooled (TEFC) design, this centrifugal fan prioritizes environmental comfort and safety. Its Class F insulation and sealed bearings offer added protection from dust, moisture, and external contaminants, meeting rigorous industrial standards.

FAQs of DIDW Centrifugal Fan 455 MM X 305 MM:

Q: How is the DIDW Centrifugal Fan installed and what are its mounting requirements?

A: This centrifugal fan is base mounted, allowing installation on flat surfaces in HVAC or industrial settings. Installation should follow manufacturer guidelines, ensuring secure mounting and proper alignment to support the belt-driven system and maximize performance.Q: What applications is the DIDW Centrifugal Fan suitable for?

A: It is specifically engineered for HVAC systems and industrial ventilation. The robust build and motor specifications make it ideal for environments that demand efficient air flow and reliable operation, such as factories, commercial buildings, and large-scale facilities.Q: When should scheduled maintenance be performed on this fan?

A: Routine maintenance is recommended every 6 to 12 months, focusing on belt tension, bearing lubrication, and inspection of electrical connections. Thanks to its sealed ball bearings and TEFC enclosure, maintenance demands are lower compared to open-ventilated fans.Q: Where can this centrifugal fan be utilized within industrial or commercial operations?

A: This fan can be operated in machine rooms, production zones, ventilation ducts, and air handling units, particularly where temperatures range from -10C to +60C. Its enclosure and insulation class ensure dependable performance in a variety of environments.Q: What process does the fan use to deliver high static efficiency?

A: The backward curved impeller and belt-driven mechanism enhance aerodynamic flow, reducing power losses and maximizing static efficiencyover 75%. Together with the 12-blade design, it produces consistent air movement and optimal pressure output.Q: How does using this centrifugal fan benefit my facilitys operation?

A: Users gain reliable, high-capacity ventilation with reduced energy consumption, quieter performance, and a long operational lifespan. The sturdy design and efficient motor minimize downtime, supporting continuous air quality management in demanding settings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 180 MM X 203 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power : 80 W

Life Span : 10 Years

Weight : 4.5 kg

Output Power : 0.18 HP

DIDW Centrifugal Fan 151 MM X 203 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Power : 1 HP

Life Span : 10 Years

Weight : 15 kg

Output Power : 0.75 kW

DIDW Centrifugal Fan 230 MM X 178 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Power : 0.75 kW

Life Span : More than 20,000 hours

Weight : Approx. 7.5 kg

Output Power : 0.75 kW

DIDW Centrifugal Fan 250 MM X 228 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power : 0.75 kW

Life Span : 40,000 hours (typical)

Weight : Approx. 12 kg

Output Power : 0.75 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS