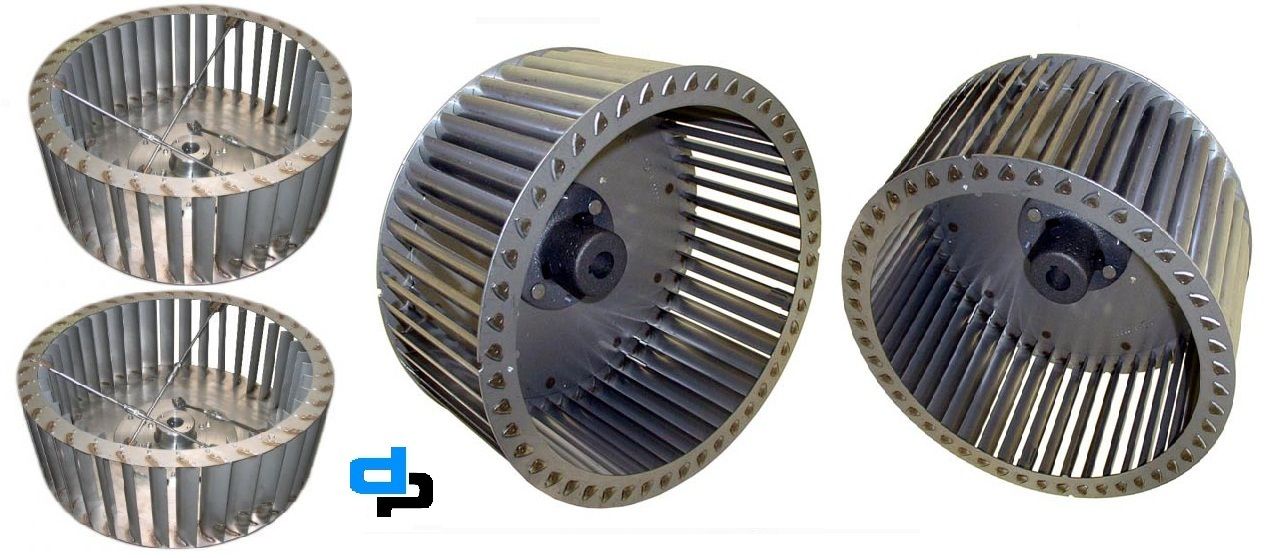

DIDW Centrifugal Fan 280 MM X 305 MM

DIDW Centrifugal Fan 280 MM X 305 MM Specification

- Pressure Range

- 10 - 50 mm WG

- Motor Power

- 1 HP

- Life Span

- 5-7 Years

- Max Pressure

- 50 mm WG

- Output Power

- 0.75 kW

- Flow Rate

- 1200-1700 m/h

- Power

- 0.75 kW - 1.5 kW

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 1200-1700 m/h

- Pressure

- Up to 50 mm WG

- Application

- Ventilation, Air Handling Units, Industrial Exhaust

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2900 RPM

- Noise Level

- Below 80 dB

- Power Source

- Electric

- Voltage

- 220-415 V

- Weight

- Approx 12 kg

- Dimension (L*W*H)

- 280 mm x 305 mm

- Color

- Blue

DIDW Centrifugal Fan 280 MM X 305 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Kerala, Central India, West India, Chhattisgarh, All India

About DIDW Centrifugal Fan 280 MM X 305 MM

DIDW Centrifugal Fan 280 MM X 305 MM

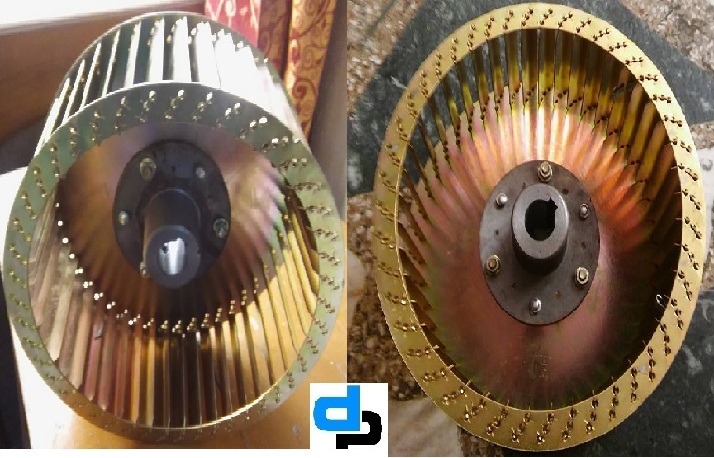

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 47 | DP 11 12 | 280 X 305X 236 | 11 X 12 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Versatile Performance for HVAC and Industrial Applications

This centrifugal fan is engineered to meet versatile air movement needs, making it suitable for HVAC ventilation, air handling units, and various industrial exhaust systems. Its wide pressure and flow rate capacities ensure it adapts well to diverse operational demands, promising maximum efficiency with minimal noise.

Reliable Construction and Easy Installation

Constructed from powder-coated mild steel and fitted with ball bearings, the fan offers durability and long service life. The base mounted design and rectangular or square inlet/outlet options facilitate straightforward installation in both commercial and industrial settings.

FAQs of DIDW Centrifugal Fan 280 MM X 305 MM:

Q: How does the DIDW Centrifugal Fan improve air quality in HVAC and industrial systems?

A: The fan circulates large volumes of air efficiently, maintaining optimal ventilation and removing contaminants in enclosed spaces, which is crucial for both comfort and safety in HVAC and industrial environments.Q: What is the recommended process for installing this centrifugal fan?

A: Mount the fan on a stable base, connect the electrical supply (220-415 V, 50 Hz), and ensure the rectangular or square duct matches the inlet/outlet. Verify alignment with drive type (belt or direct coupled) and secure all connections before operation.Q: Where can the DIDW Centrifugal Fan be used effectively?

A: This fan is commonly installed in air handling units, ventilation ductwork, and for industrial exhaust applications, especially in factories, commercial buildings, and large-scale HVAC systems across India.Q: What benefits does the double inlet double width impeller design provide?

A: The double inlet double width design enables higher airflow capacity while maintaining compact dimensions, delivering efficient air movement and quieter operation compared to standard impellers.Q: When should the fan be serviced to ensure optimal performance?

A: Regular maintenance is suggested every 6 to 12 months, including cleaning the impeller and housing, checking ball bearings, and inspecting belt/direct drive alignment to preserve efficient operation over its 5-7 year lifespan.Q: What is the maximum operating temperature and pressure for this fan?

A: The fan performs reliably at operating temperatures ranging from -10C to 60C and can handle pressure up to 50 mm WG, making it suitable for diverse climate and operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 151 MM X 127 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Noise Level : 68 dB

Color : Grey

Capacity : 200 CFM

Dimension (L*W*H) : 151 mm x 127 mm

DIDW Centrifugal Fan 100 MM X 100 MM

Price 750 INR

Minimum Order Quantity : 5 Pieces

Noise Level : 68 dB(A)

Color : Silver

Capacity : 300 m/h

Dimension (L*W*H) : 100 mm x 100 mm

DIDW Centrifugal Fan 250 MM X 254 MM

Price 3000 INR

Minimum Order Quantity : 5 Pieces

Noise Level : Below 75 dB

Color : Blue

Capacity : 1500 m/hr

Dimension (L*W*H) : 250 mm x 254 mm

DIDW Centrifugal Fan 151 MM X 203 MM

Price 1000 INR

Minimum Order Quantity : 5 Pieces

Noise Level : Below 80 dB

Color : Blue

Capacity : 700 CFM

Dimension (L*W*H) : 151 mm x 203 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS