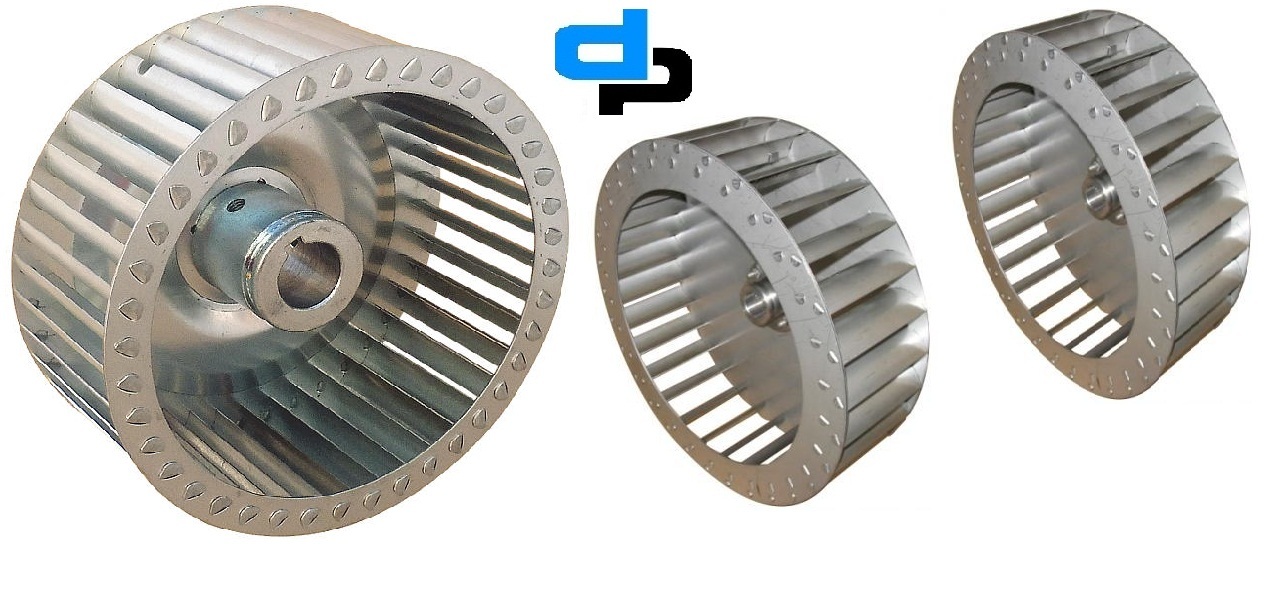

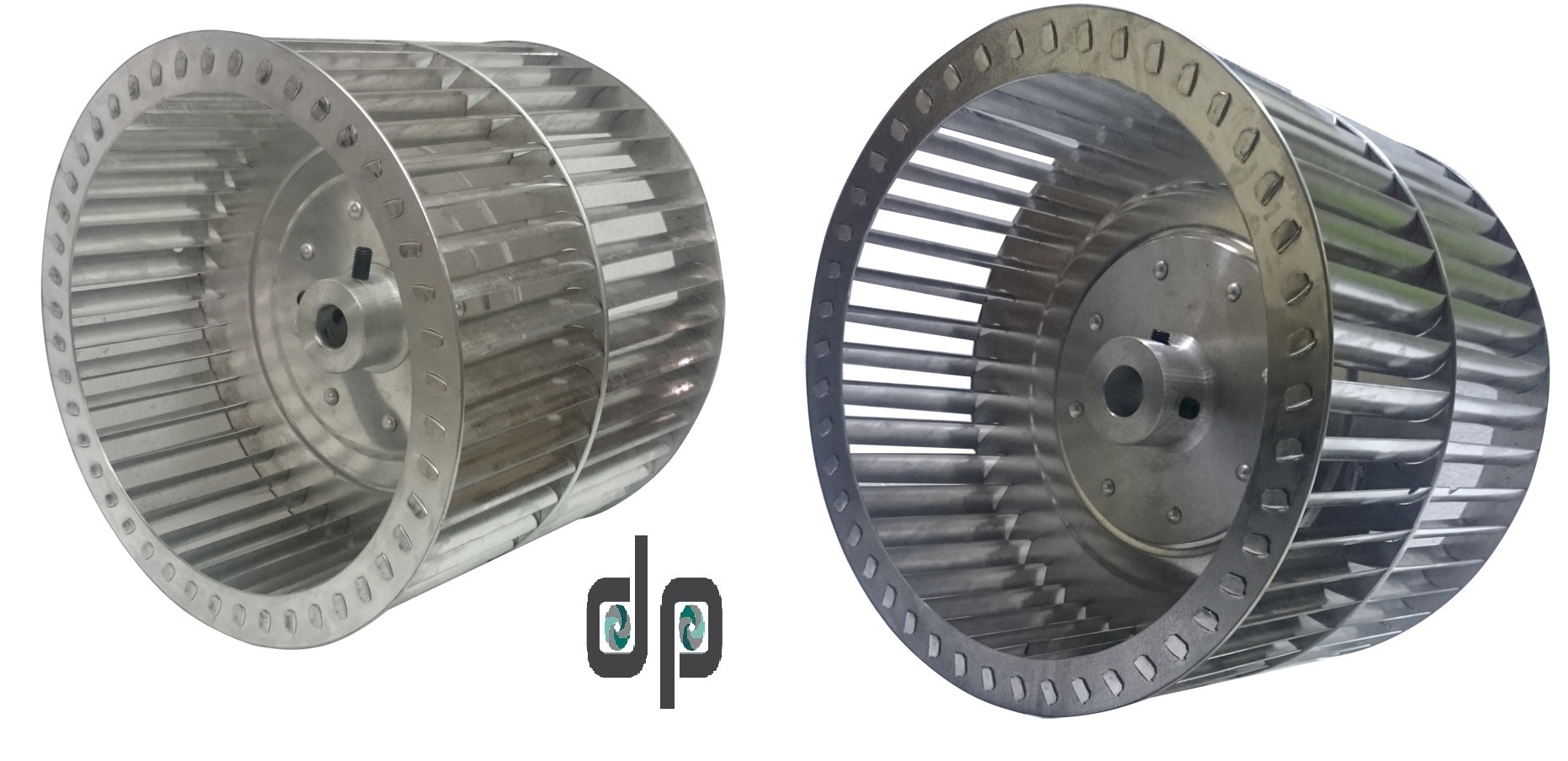

DIDW Centrifugal Fan 180 MM X 254 MM

DIDW Centrifugal Fan 180 MM X 254 MM Specification

- Flow Rate

- 820 CFM

- Life Span

- 8-10 years

- Output Power

- 0.75 kW

- Motor Power

- 1 HP

- Pressure Range

- 90-140 mm WG

- Max Pressure

- 140 mm WG

- Power

- 0.75 kW

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 820 CFM

- Pressure

- 140 mm WG

- Application

- Ventilation, Industrial Exhaust, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- 75 dB

- Power Source

- Electric

- Voltage

- 230/415 V

- Weight

- Approx. 12 kg

- Dimension (L*W*H)

- 180 mm x 254 mm

- Color

- Silver / Grey

- Fan Housing

- Heavy Duty Mild Steel

- Insulation Class

- Class F

- Mounting Type

- Base Mounted

- Drive Type

- Direct / Belt Driven

- Air Flow Direction

- Axial

- Impeller Type

- Double Inlet Double Width (DIDW)

- Temperature Resistance

- Up to 80°C

- Enclosure

- IP55 Motor Enclosure

- Finish

- Powder Coated

- Suitable For

- HVAC, Industrial Ventilation, Clean Room Applications

- Number of Blades

- 12

- Blade Material

- Mild Steel

DIDW Centrifugal Fan 180 MM X 254 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Pondicherry, South India, North India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Lakshadweep, Haryana, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Uttar Pradesh, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Gujarat, Delhi, East India, Andhra Pradesh, Central India, Jharkhand, Chhattisgarh, All India

About DIDW Centrifugal Fan 180 MM X 254 MM

DIDW Centrifugal Fan 180 MM X 254 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 22 | DP 7 10 | 180 X 254 X 153 | 7 X 10 | 12.70 (1/2'') & 15 MM | AL. / GI. |

Efficient Airflow Solution for Industrial Applications

This centrifugal fan is engineered for high efficiency and reliability, supporting a range of ventilation, exhaust, and air handling needs in industrial and clean room settings. Its double inlet double width impeller, combined with a 12-blade setup, delivers powerful and consistent airflow. The IP55 motor enclosure and Class F insulation provide robust protection, making it suitable for challenging environments.

Durability and Performance

Constructed with heavy-duty mild steel and powder-coated for enhanced longevity, this fan ensures stable operation and low maintenance costs. The base-mounted design allows for straightforward installation, while its motor accommodates both direct and belt-driven systems. Operating at up to 2800 RPM, it sustains a flow rate of 820 CFM, addressing demanding ventilation requirements.

FAQs of DIDW Centrifugal Fan 180 MM X 254 MM:

Q: How is the DIDW Centrifugal Fan typically installed and where can it be used?

A: This base-mounted fan is straightforward to install and ideal for environments such as HVAC systems, industrial ventilation, clean rooms, and air handling units. Its compact size and robust construction allow for placement in both commercial and industrial spaces.Q: What are the main benefits of choosing a double inlet double width (DIDW) impeller design?

A: The DIDW impeller ensures higher airflow with lower turbulence and improved efficiency. This design is particularly beneficial in applications requiring a steady, axial air stream across wider service areas.Q: When should maintenance be performed on this centrifugal fan?

A: Routine maintenance, including checking for dust buildup and ensuring the motor enclosure remains sealed, is recommended every six months, or more frequently in harsh industrial settings, to maximize lifespan and maintain peak performance.Q: What kind of environments is the DIDW Centrifugal Fan suitable for given its specifications?

A: Thanks to its IP55 motor enclosure, powder-coated mild steel construction, and ability to operate up to 80C, the fan is ideal for demanding settings such as factories, laboratories, commercial HVAC applications, and clean rooms.Q: How does the fan handle high temperatures or continuous use?

A: With Class F motor insulation and heavy-duty mild steel housing, the fan is built to resist temperatures up to 80C. These features allow reliable long-term operation even under continuous-use conditions typical in industrial settings.Q: What are the noise levels during operation, and can the fan be used in noise-sensitive areas?

A: The average operational noise level is around 75 dB. For environments where minimal noise is critical, sound dampening measures can be incorporated during installation.Q: What is the process for selecting the appropriate drive type for this fan?

A: Selection between direct and belt-driven configurations depends on application needs. Direct drive offers lower maintenance and higher efficiency, whereas belt-driven systems provide easier speed adjustments and are preferable where variable air volume is required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 250 MM X 150 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Weight : Approx. 15 kg

Color : Grey

Flow Rate : Up to 1200 m/h

DIDW Centrifugal Fan 250 MM X 178 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Weight : Approx 12 kg

Color : Silver Grey

Flow Rate : 8001000 CFM

DIDW Centrifugal Fan 530 MM X 455 MM

Price 21000.00 INR

Minimum Order Quantity : 1 Piece

Power Source : Other, Electric

Weight : 52 kg

Color : Silver Grey

Flow Rate : 34003700 m/h

DIDW Centrifugal Fan 230 MM X 254 MM

Price 2500 INR

Minimum Order Quantity : 5 Pieces

Power Source : Other, Electric

Weight : 8.5 kg (approx.)

Color : Silver/Grey

Flow Rate : 600 CFM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS