Cooling Air Blower

Cooling Air Blower Specification

- Output Power

- 1.5 kW

- Flow Rate

- 3500 m/hr

- Pressure Range

- 1500-2500 Pa

- Life Span

- 8-10 Years

- Power

- 1.5 kW

- Motor Power

- 2 HP

- Max Pressure

- 2500 Pa

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Capacity

- 3500 m/hr

- Pressure

- 2500 Pa

- Application

- Industrial Cooling

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2800 RPM

- Noise Level

- <75 dB

- Power Source

- Electric

- Voltage

- 220 V

- Weight

- 18 kg

- Dimension (L*W*H)

- 520 x 350 x 400 mm

- Color

- Blue

About Cooling Air Blower

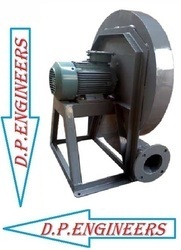

Cooling Air Blower

We offer to the patrons an excellent range of Cooling Air Blower for HVAC which has been made using an outstanding quality of raw materials which have been sourced from renowned vendors in the market who are highly dependable and are popular in the industry for their quality products. Our products are highly hard-wearing and they are very robust in their construction. We offer these products to the patrons at very logical rates in the market.

Features:

- Corrosion and abrasion resistant

- Accurate

- Longer life

- Pocket friendly range

- Air Volume

- Air Pressure

- Motor H.P.

- Blower R.P.M.

- Operating Temp

- Drive Type

- Construction of Material (M.O.C.)

Ceramic and Refractories Industries, Chemical Factories, Cement Plants, Crucible Furnaces, Furnaces like Oil, Gas, Cupola Furnaces, Flour Mills, Rolling Mills, Boilers, Textile Mills, Cattle Feed Plants, Pharmaceutical Industries, Fertilizer Industries, Plastic Machinery Plants, Hot Mix Plants, Iron and Steel Plants, Paper Industries, Process Industries, and many more.

Use of Cooling Air Blowers HVAC:

As Supply and Exhaust fans in Ventilation systems, In air handling units for air conditioning systems, In cold storage plants, For fume extraction in industrial plants, Industrial Blowers/Fans are widely used in Ventilation, Pollution Control, Fume Extraction, Dust collection, Induced Draft(ID Fans) and Forced Draft (F.D.Fans) for Boilers and Furnaces, suitable for various applications for Cooling, Humidification, Ventilation, Gas exhaust fans, Exhausters, fresh air supply, HVAC duties, Combustion for Burners, Recirculation of Fresh and United Air, etc.

also Manufacturer, Supplier, Export, of Different Blowers, like Single Inlet Single Width Centrifugal Backward/Forward Curve Blowers (SISW Blowers), Airfoil Blowers, DIDW Blowers, Centrifugal Blowers, Air Blowers, Exhaust Blowers, Combustion Blowers, High Pressure Blowers, Low Pressure Blowers, Forced Draft Blowers(F.D.Fans), Induced draft Blowers(I.D.Fans), and all types of Industrial Fans.

Cooling Air Blowers HVAC Features:

High efficiency, Low sound level, Compact Design, Large sizes can be dismantled, More Air with less HP, Easy in operation, Smooth in Running, Several versions available, etc.

Cooling Air Blowers HVAC are available in Three different Drives:

Direct Drive Cooling Air Blowers HVAC: All direct motor drive Cooling Air Blowers HVAC are supplied with suitable Electric motor with Fan cooling and also Flame Proof.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Reliable Performance for Industrial Cooling

Engineered for demanding industrial conditions, this cooling air blower provides consistent airflow and pressure. Its base-mounted configuration and robust IP54 enclosure ensure stable operation even in harsh environments. With a direct drive motor and Class F insulation, the blower offers dependable and long-lasting performance.

High-Efficiency Airflow and Durable Construction

Delivering up to 3500 m/hr airflow at pressures up to 2500 Pa, the unit efficiently cools large spaces and equipment. The impellers aluminium construction and the mild steel body resist wear and corrosion, ensuring longevity. Its compact design and moderate weight make it easy to install and maintain in a variety of industrial setups.

FAQs of Cooling Air Blower:

Q: How should the Cooling Air Blower be installed for optimal performance?

A: For best results, the blower should be base mounted on a stable surface, ensuring alignment with your ventilation system. Proper electrical connections to a 220 V supply and secure anchoring will help the unit operate efficiently and minimize vibration.Q: What are the key benefits of using this axial flow blower in industrial environments?

A: This blower offers high airflow capacity (3500 m/hr), robust pressure performance (up to 2500 Pa), and efficient cooling for industrial applications. Its durable construction, IP54 enclosure, quiet operation, and long service life make it an excellent choice for reliable operation in challenging industrial settings.Q: Where can this Industrial Cooling Air Blower be effectively utilized?

A: The blower is suited for various industrial sites, such as manufacturing units, processing plants, or workshops, where heat dissipation and equipment cooling are critical. Its ability to function within temperatures from -10C to +60C ensures versatility in diverse operational environments.Q: What is the typical maintenance process for this air blower?

A: Regular maintenance includes inspecting the impeller and motor for dust or debris, tightening mounting bolts, and checking the electrical connections. Keeping filters clean (if applicable) and ensuring the airflow paths remain unobstructed will prolong the blowers lifespan and maintain optimal efficiency.Q: How does the air-cooled design enhance the blowers performance and durability?

A: The air-cooled mechanism efficiently dissipates heat generated during operation without requiring additional cooling systems. This reduces complexity, lowers maintenance needs, and extends component life, allowing for continuous and stable performance.Q: When can users expect to replace the blower, considering its lifespan?

A: The blower is engineered for longevity, typically requiring replacement after 8 to 10 years of normal industrial use, provided maintenance is performed as recommended.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Blower Category

Commercial Blower

Application : Air ventilation industrial applications, Other

Product Type : Commercial Blower, Others

Frequency (MHz) : Undefined

Color : Gray

Power Source : Electric, Other

Material : other , Metal

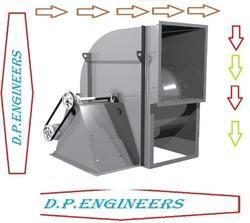

Gas Blower

Application : Other, Industrial Gas Firing, Combustion Systems, Furnace Air Supply

Product Type : Others, Industrial Gas Blower

Frequency (MHz) : 50 Hz

Color : Silver / Grey

Power Source : Other, Electric

Material : other , Mild Steel

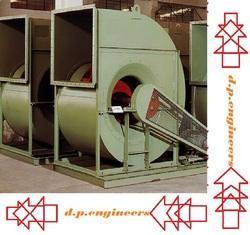

Ventilation Centrifugal Air Blower

Application : Other, Ventilation, HVAC, Industrial Exhaust

Product Type : Others, Centrifugal Air Blower

Frequency (MHz) : 50 Hz

Color : Blue

Power Source : Other, Electric

Material : other , Mild Steel

Direct Driven Fan 10 Inch X 10 Inch

Application : Industrial

Product Type : Exhaust Air Blower, Others

Frequency (MHz) : 50/60 Hertz(Hz)

Power Source : Electric Blower

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS