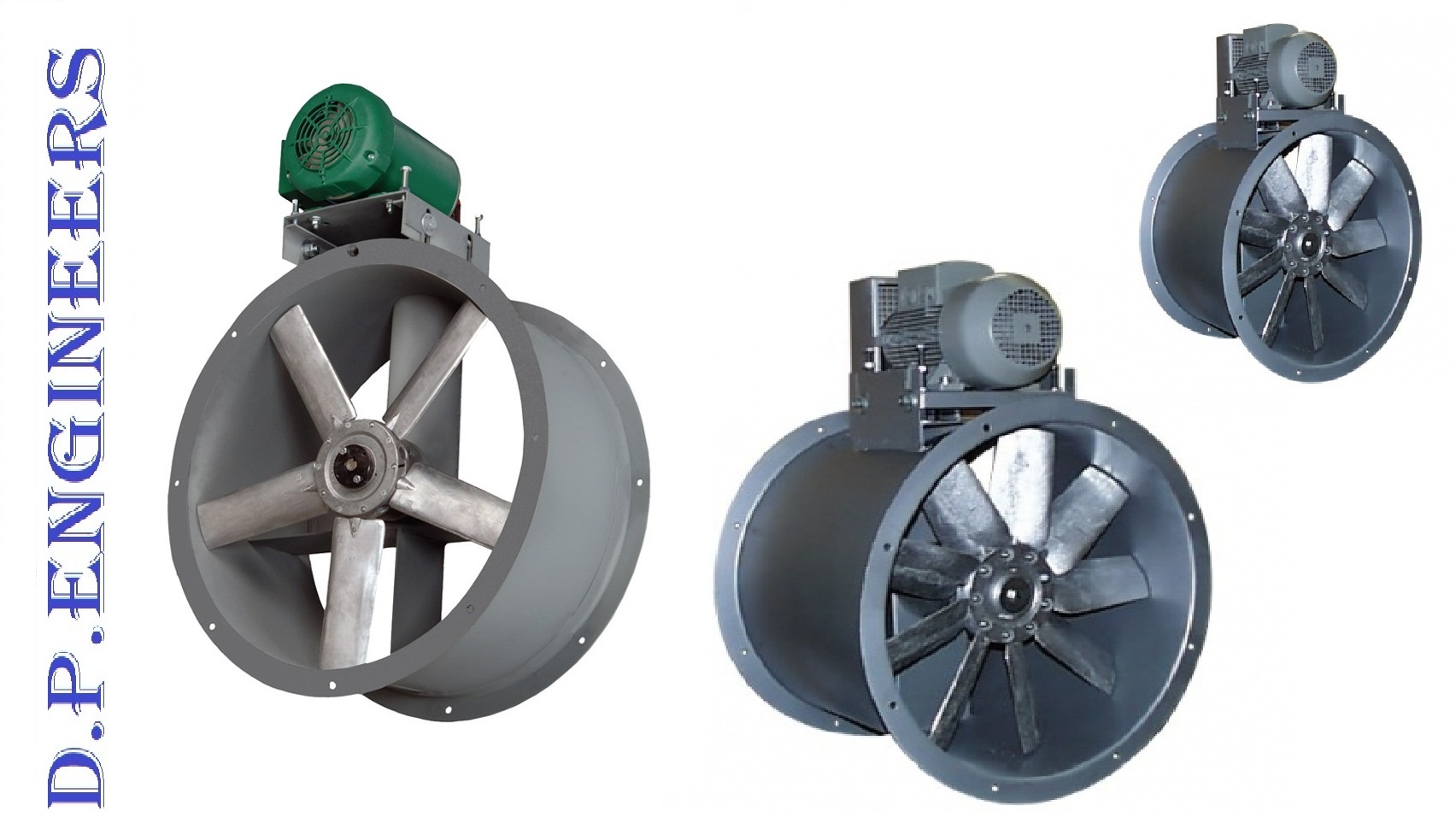

Belt Driven Axial Flow Fan

Belt Driven Axial Flow Fan Specification

- Air Volume

- 12000-50000 m/h

- Power

- 2.2 kW - 15 kW

- Revolution

- Single/Double

- Noise Level

- 80 dB

- Pressure

- 60-250 Pa

- Speed

- 960-1450 RPM

- Voltage

- 220V/380V

- Power Consumption

- Varies by model

- Product Type

- Belt Driven Axial Flow Fan

- Type of Fan

- Axial Flow Fan

- Power Mode

- AC Electric

- Installation Type

- Duct Mounted / Wall Mounted

- Blade Material

- Aluminum Alloy

- Shape

- Round

Belt Driven Axial Flow Fan Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, Australia, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, North America

- Main Domestic Market

- All India

About Belt Driven Axial Flow Fan

Belt Driven Axial Flow Fan

We are a range of Belt Driven Axial Flow Fan that are used for air conditioning, industrial ventilation and fumes. These are fabricated from mild steel plates and have been provided with foot mounting arrangements and flange on both ends that facilities installation of the fan.

Features:

- Large air volumes

- Low power consumption

- Easy to install

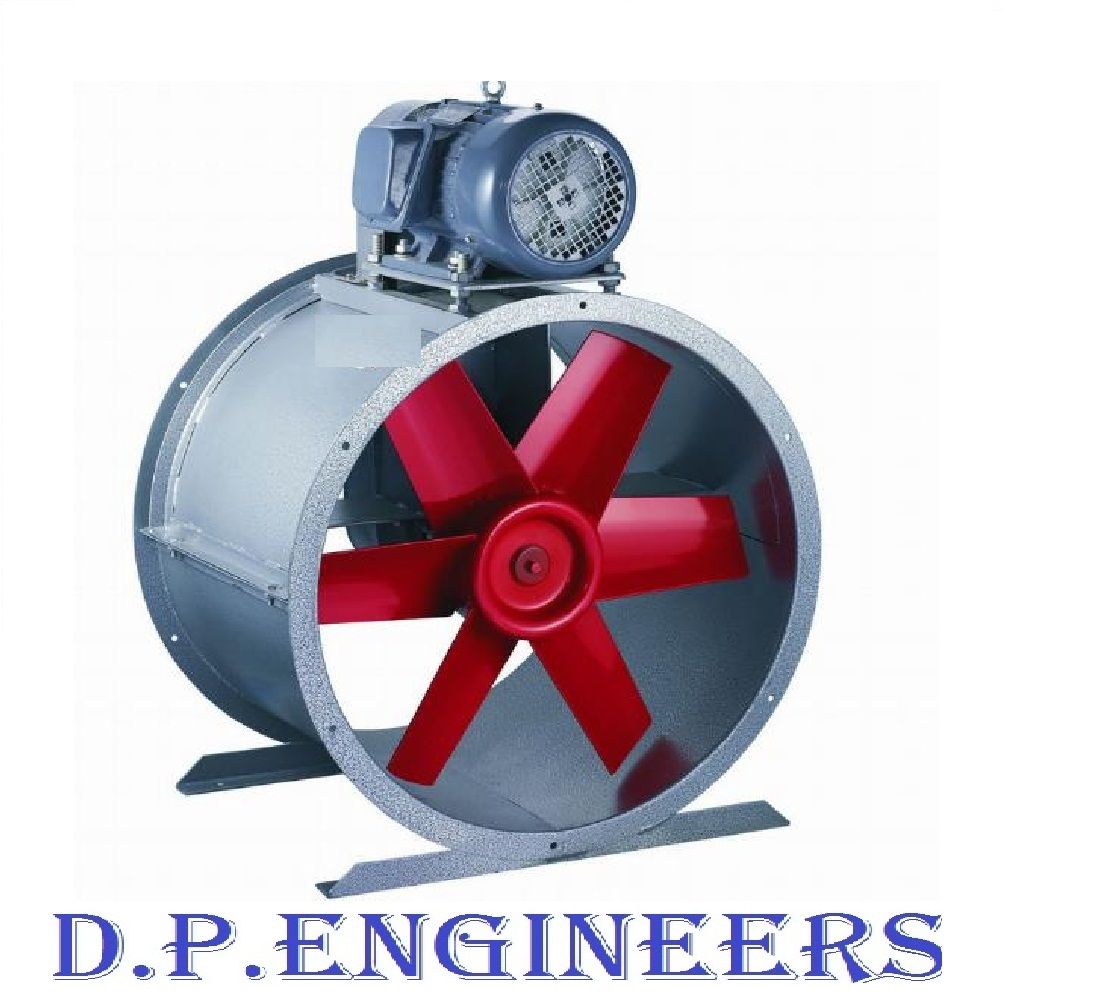

Versatile Mounting and Installation

These axial flow fans offer flexible installation options, suitable for duct or wall mounting in both horizontal and vertical positions. Their user-friendly design allows for tailored integration into industrial ventilation and exhaust systems, optimizing air movement according to specific spatial requirements.

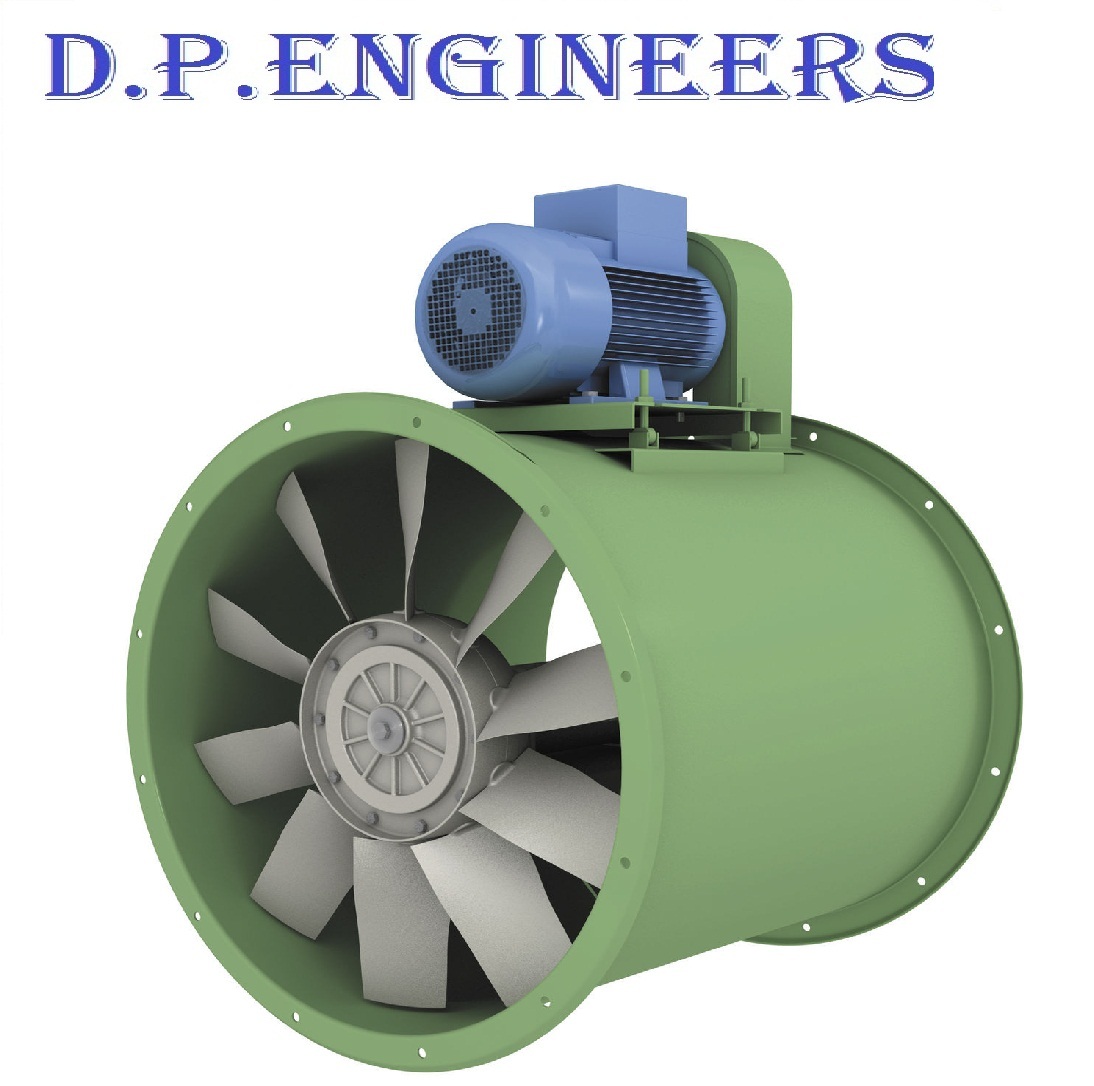

Powerful Performance and Efficiency

Constructed with a V-belt drive mechanism, these fans deliver efficient air flow ranging from 12,000 to 50,000 m/h. Their speed (9601450 RPM) and pressure (60250 Pa) can be selected to suit various industrial needs, all while maintaining a noise level of 80 dB for a less disruptive operational environment.

Durability and Corrosion Resistance

Each unit is built from strong mild or galvanized steel, protected by a powder-coated finish for superior durability. With high-grade aluminum alloy blades, these fans are designed to withstand harsh industrial environments and accommodate an operating temperature range from -10C to +50C.

FAQs of Belt Driven Axial Flow Fan:

Q: How is the belt driven axial flow fan typically installed in industrial settings?

A: This fan is designed for flexible installation, supporting both duct-mounted and wall-mounted configurations, in either horizontal or vertical orientations. Installation should be performed by qualified technicians to ensure optimal performance and adherence to safety standards.Q: What are the primary benefits of using a V-belt driven axial flow fan with an external motor location?

A: V-belt driven fans with external motor positioning keep the motor out of the air stream, reducing exposure to heat, moisture, and particulates. This enhances both safety and the service lifespan of the motor while providing more efficient and reliable ventilation.Q: When should I consider using a fan with 6-12 blades and a diameter range of 400 mm to 1400 mm?

A: Fans with 612 blades and diameters from 400 mm to 1400 mm are ideal when you need to move large volumes of air or ensure robust ventilation in medium to large industrial spaces. The customizable blade count optimizes air flow and pressure to suit specific application needs.Q: Where can these axial flow fans be used most effectively?

A: These fans are well-suited for use in factories, warehouses, workshops, and other industrial environments in need of ventilation, process exhaust, and environmental air movement. Their adaptability allows integration into various ducted or open-air systems.Q: What is the typical process for selecting the correct axial flow fan model?

A: Selection involves assessing your air volume requirements (12,00050,000 m/h), required pressure (60250 Pa), installation space, temperature range, desired noise level, and available power supply (220V/380V). Consulting with the manufacturer or supplier can help match these variables to the right model for your facility.Q: How does the powder-coated finish benefit the fans longevity?

A: The powder-coated finish provides a tough, corrosion-resistant layer that shields the frame and components from harsh industrial conditions, extending the fans operational life and preserving its appearance even in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Axial Flow Fan Category

Case Axial Flow Fan

Minimum Order Quantity : 1 Piece

Power Consumption : Varies by Model

Power Mode : Electric

Installation Type : Other, Duct Mounted / Wall Mounted

Voltage : 220V/380V

Blade Material : Other, Aluminium

Ventilation Axial Fan Duct

Minimum Order Quantity : 1 Piece

Power Consumption : Depends on Model

Power Mode : Electric

Installation Type : Other, Duct Mount

Voltage : 220/380 V

Blade Material : Other, Galvanized Steel

Bifurcated Axial Flow Fan

Minimum Order Quantity : 5 to 10 Pieces

Power Consumption : 0.75 kW 15 kW (as per model)

Power Mode : Electric

Installation Type : Other, Duct Mounted

Voltage : 220V / 380V AC

Blade Material : Aluminum Alloy

V-Belt Driven Axial Flow Fan

Minimum Order Quantity : 1 Piece

Power Consumption : Depends on model

Power Mode : Other, VBelt Drive

Installation Type : Other, Wall Mounted / Duct Mounted

Voltage : 220/380 V

Blade Material : Other, Aluminium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS