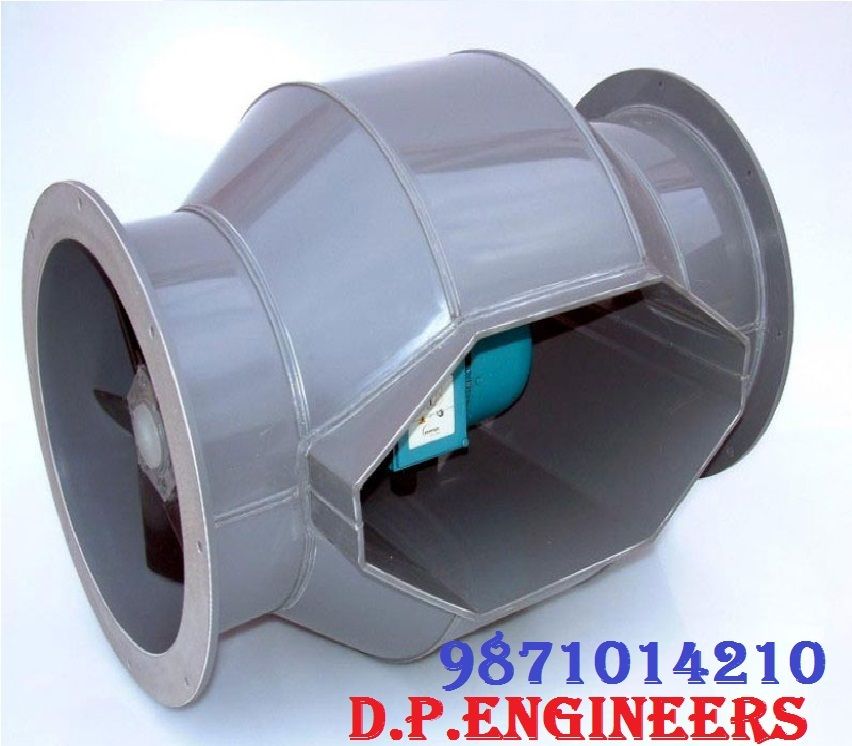

Bifurcated Axial Flow Fan

Bifurcated Axial Flow Fan Specification

- Power Consumption

- 0.75 kW 15 kW (as per model)

- Air Volume

- 2000-15000 m/h

- Revolution

- Direct Drive or Belt Driven

- Speed

- 960-2880 RPM

- Power

- 1 HP 20 HP (depending on model)

- Noise Level

- <85 dB

- Pressure

- 60-350 Pa

- Voltage

- 220V / 380V AC

- Product Type

- Bifurcated Axial Flow Fan

- Type of Fan

- Axial Flow Fan

- Power Mode

- Electric

- Installation Type

- Duct Mounted

- Blade Material

- Aluminum Alloy

- Shape

- Round

Bifurcated Axial Flow Fan Trade Information

- Minimum Order Quantity

- 5 to 10 Pieces

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, South America, Africa, Central America, Western Europe, Asia

- Main Domestic Market

- All India

About Bifurcated Axial Flow Fan

Bifurcated Axial Flow Fan

We are a celebrated manufacturer, exporter, supplier and trader of Bifurcated Axial Flow Fan. It can be installed at any angle in a duct line with its motor compartment isolated from fumes. And for horizontal or near horizontal positions a drain plug can be fitted at the lowest part of the casing. In addition to this, offered Bifurcated Axial Flow Fan is a direct driven axial fan, where the motor is encased in a metal box to isolate it from the airflow.

Features:

- Sturdy construction

- Energy efficient

- Affordable

Type: -

- Wheel Diameter : 500mm - 1000mm

- PERFORMANCE : 1250 -73000 CMH up to 40MM WG SP,

- MOUNTING: In line duct and or wall mounting.

- APPLICATION: These fans are suitable for handling hot, corrosive and inflammable gases. Motor remain outside the air stream.

Engineered for Harsh Industrial Environments

Designed to endure hazardous, chemical, and humid atmospheres, the bifurcated axial flow fan offers robust ventilation solutions. Its high corrosion resistance and epoxy-coated finish ensure optimal performance and extended operational life, even in challenging settings.

Versatile Configuration and Performance

Available in multiple blade counts and impeller types, as well as material choices like stainless steel, mild steel, or aluminum, this fan can be tailored to specific project requirements. Its broad capacity range and direct or belt-driven options suit diverse applications from ventilation to exhaust.

Safety and Efficiency Prioritized

The fan is equipped with a totally enclosed, optionally flameproof motor, safeguarding operations in volatile environments. Precision engineering keeps noise levels below 85 dB, while high airflow efficiency and a wide voltage range ensure reliable, economical operation.

FAQs of Bifurcated Axial Flow Fan:

Q: How does the bifurcated axial flow fan ensure safe operation in hazardous and corrosive environments?

A: This fan is constructed using corrosion-resistant materials such as mild steel, stainless steel, or aluminum, and features an epoxy powder-coated frame for added protection. The totally enclosed or optional flameproof motor further enhances operational safety, making it ideal for chemical plants or humid environs.Q: What blade and impeller configurations are available, and how do they impact performance?

A: You can choose from 4, 6, or 8 blades in aerofoil, flat, or curved designs. The selection affects airflow characteristics: aerofoil blades provide high efficiency, flat and curved blades are suitable for diverse pressure needs. This flexibility allows optimization according to ventilation or exhaust requirements.Q: Where can the bifurcated axial flow fan be installed and used?

A: It is designed for duct-mounted installations and is commonly used in industrial areas needing reliable ventilation, such as factories, chemical processing facilities, fume extraction systems, or hazardous material storage. It can be mounted horizontally or vertically to suit different duct layouts.Q: What operating conditions can the fan handle?

A: The fan is built to function in temperatures from -20C to 80C and pressures of 60350 Pa. Its robust build and high corrosion resistance mean it performs reliably even in environments with high chemical content or humidity.Q: What are the power and airflow capabilities of this fan?

A: Depending on the chosen model, the fan supports air volumes ranging from 2,000 to 15,000 m/h, with power ratings from 1 HP up to 20 HP. It operates on 220V or 380V AC, and consumes between 0.75 kW and 15 kW, ensuring efficient operation for various industrial needs.Q: Is remote control available for this fan, and how is it typically operated?

A: Remote control functionality is not included. The fan is designed for manual or automated operation via connected control panels, emphasizing reliable, direct management in industrial settings.Q: What are the main benefits of using the bifurcated axial flow fan for industrial applications?

A: Key advantages include high corrosion resistance, flexible configuration, support for hazardous environments, energy efficiency, and a long service life thanks to its durable materials and epoxy finish. The fans adaptability allows it to meet a wide range of ventilation and exhaust requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Axial Flow Fan Category

Tube Axial Flow Fan

Minimum Order Quantity : 1 Piece

Revolution : 1440 rev/min

Air Volume : 5000 CFM

Power Consumption : 2.2 kW

Power : 3 HP

Product Type : Other, Ventilation Fan

Wall Mounted Tube Axial Fan

Minimum Order Quantity : 1 Piece

Revolution : 1440 rpm

Air Volume : 25008500 CFM

Power Consumption : 0.552.2 kW

Power : 0.55 kW

Product Type : Other, Wall Mounted Tube Axial Fan

Case Axial Flow Fan

Minimum Order Quantity : 1 Piece

Revolution : Adjustable

Air Volume : 400060000 m/h

Power Consumption : Varies by Model

Power : 0.377.5 kW

Product Type : Other, Industrial Ventilation Fan

Industrial Tube Axial Flow Fan

Minimum Order Quantity : 1 Piece

Revolution : Single / Double

Air Volume : 5000 60000 m/h

Power Consumption : As per model

Power : 0.75 kW 15 kW

Product Type : Other, Industrial Fan

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS