Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-1KPA

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-1KPA Specification

- Outer Size

- Approx. 60mm Diameter

- Grade

- Industrial

- Sensor Type

- Differential Pressure

- Thread

- 1/8 NPT

- Display

- Analog

- Seal Material

- Rubber

- Material

- Polycarbonate, Brass

- Dial Material

- Plastic

- Pointer Material

- Plastic

- Processing Type

- Injection Molded

- Diameter

- 60 mm

- Glass Size

- Approx. 45 mm

- Mount Type

- Surface Mount

- Scale Range

- 0-1 kPa

- Accuracy

- 2% of Full Scale

- Finishing

- Black Polycarbonate Casing

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Screws included

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-1KPA Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Asia

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Nagaland, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Haryana, Madhya Pradesh, North India, Kerala, Central India, Odisha, Chhattisgarh, Karnataka, All India

About Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-1KPA

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-1KPA

Description

Mounts in Industry Standard Holes

Accuracy 5%

Low-Cost Miniature Size

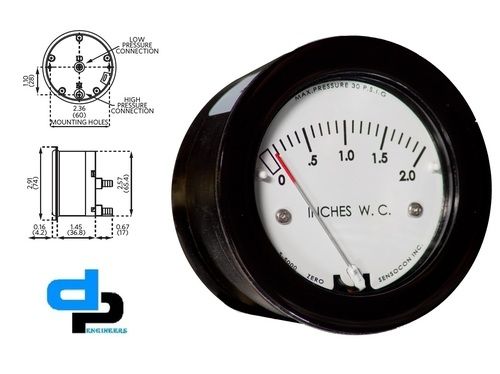

The Series Sz-5000 is a low cost, diaphragm operated, differential pressure gauge in a miniature housing. The Sz-5000 can be used in applications for measuring positive, negative, or differential pressure with an accuracy of 5%. Standard applications include monitoring filter status, duct static pressure, room pressure, fan or blower pressure, paint booths, dust collectors, and cabinet purging along with many others.

Customizing Options Available

MODEL NUMBERS

| MODEL NUMBERS | Pressure Range |

| Sz-5000-1KPA | 0 1 kPa |

SPECIFICATIONS

Pressure Limits: 30 PSI (2.067 bar)

Media Compatibility: Air and compatible non-corrosive gasses

Accuracy: +/- 5% full scale throughout range at 70F (21C)

Temperature Ranges: 20 to 120F (-7 to 49C)

Housing Material: Glass-filled nylon, polycarbonate cover

Process Connection: Barbed connections for 3/16" I.D. tubing

Weight: 6 oz (170 g)

Accessories: Two mounting studs and hex nuts, allen wrench, and panel mounting bracket

Agency Approvals: RoHS, CE

Robust Performance for Industrial Demands

Engineered for industrial reliability, the SZ-5000-1KPA gauge ensures accurate differential pressure readings for air and non-corrosive gases. The robust polycarbonate casing and brass components deliver resilience in harsh environmental conditions, while IP40 protection safeguards the device from dust infiltration. Its overpressure limit of twice the full scale further guarantees durability in demanding applications.

Versatile Application in Critical Environments

Ideal for HVAC monitoring, cleanrooms, and filter status checks, this differential pressure gauge integrates seamlessly into both new and existing setups. Accessories like mounting screws and its surface-mount design facilitate quick, flexible installation. The analog display supports clear and immediate readings, streamlining pressure monitoring for engineers and facility managers.

Precision and Simplicity in Design

The SZ-5000-1KPA combines accuracy (2% FS) with user-friendly construction. Its vertical mounting and compact body (60 mm diameter) allow for easy fitting in constrained spaces. The polycarbonate injection-molded finish ensures lasting performance while the instantaneous response time aids in rapid system diagnostics.

FAQs of Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-1KPA:

Q: How do I install the Sensocon SZ-5000-1KPA differential pressure gauge?

A: The gauge is surface mounted in a vertical position using the included mounting screws. Connect the pressure source using the 1/8" NPT female threads, ensuring compatibility with your air or non-corrosive gas system. Follow the supplied instructions for safe installation.Q: What applications is the SZ-5000-1KPA best suited for?

A: This differential pressure gauge is ideal for HVAC systems, cleanrooms, filter monitoring, and other industrial environments where precise differential pressure measurement of air or non-corrosive gases is required.Q: When should I replace or recalibrate this pressure gauge?

A: Periodic calibration, as recommended by your facilitys standards or annually, ensures optimal accuracy. Replace the gauge if you notice persistent inaccuracies, mechanical damage, or after experiencing overpressure beyond twice the full scale.Q: Where can this pressure gauge be mounted?

A: It is designed for vertical surface mounting, making it suitable for control panels, machinery, or walls in industrial and laboratory settings.Q: What is the benefit of using this analog differential pressure gauge over digital alternatives?

A: Analog gauges like the SZ-5000-1KPA provide instantaneous, reliable readings without needing power or electronic components, making them low-maintenance, easy to monitor at a glance, and highly durable for continuous use.Q: How does the overpressure protection work on this device?

A: The gauge handles up to twice its full scale (2 kPa) without damage, protecting its internal components from accidental overpressure events and prolonging product life.Q: What process is used in the manufacture of the gauge casing?

A: The outer casing is manufactured via injection molding of polycarbonate, resulting in a strong, impact-resistant, and lightweight enclosure for industrial-grade applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Differential Pressure Gauge Series Sz-5000 sensoco Category

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5010

Accessories : Mounting Screws Included

Scale Range : 010 Inch WC (Water Column), various ranges available

Measure Pressure Of : Other, Low Differential Air or Noncorrosive Gases

Diameter : Miniature, approx. 60 mm

Processing Type : Other, Injection Molded

Accuracy : 2% Full Scale

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-50MM

Accessories : Panel Mounting Bracket, Screws

Scale Range : 060 Pa

Measure Pressure Of : Other, Air / Noncorrosive Gases

Diameter : 50 mm

Processing Type : Other, Injection Moulded

Accuracy : 2% F.S.

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5002

Accessories : Panel Mounting Bracket (Optional)

Scale Range : 02000 Pa (Pascal) or 020 mm WC (Water Column)

Measure Pressure Of : Other, Air and NonCorrosive Gases

Diameter : Approximately 60 mm

Processing Type : Other, Machined and Assembled

Accuracy : 2% of Full Scale

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series Sz-5000-125PA

Accessories : Surface Mounting Bracket

Scale Range : 0125 Pa

Measure Pressure Of : Other, Air and noncorrosive gases

Diameter : 60 mm

Processing Type : Other, Injection molded case

Accuracy : 2% of full scale

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS