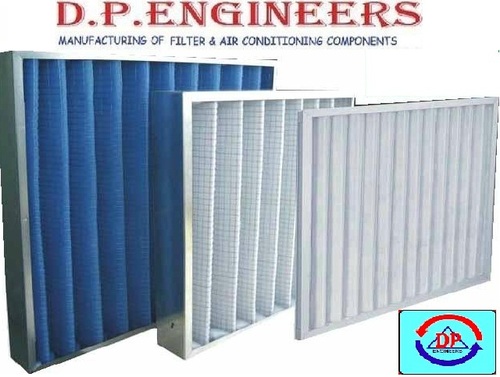

Pre Filters

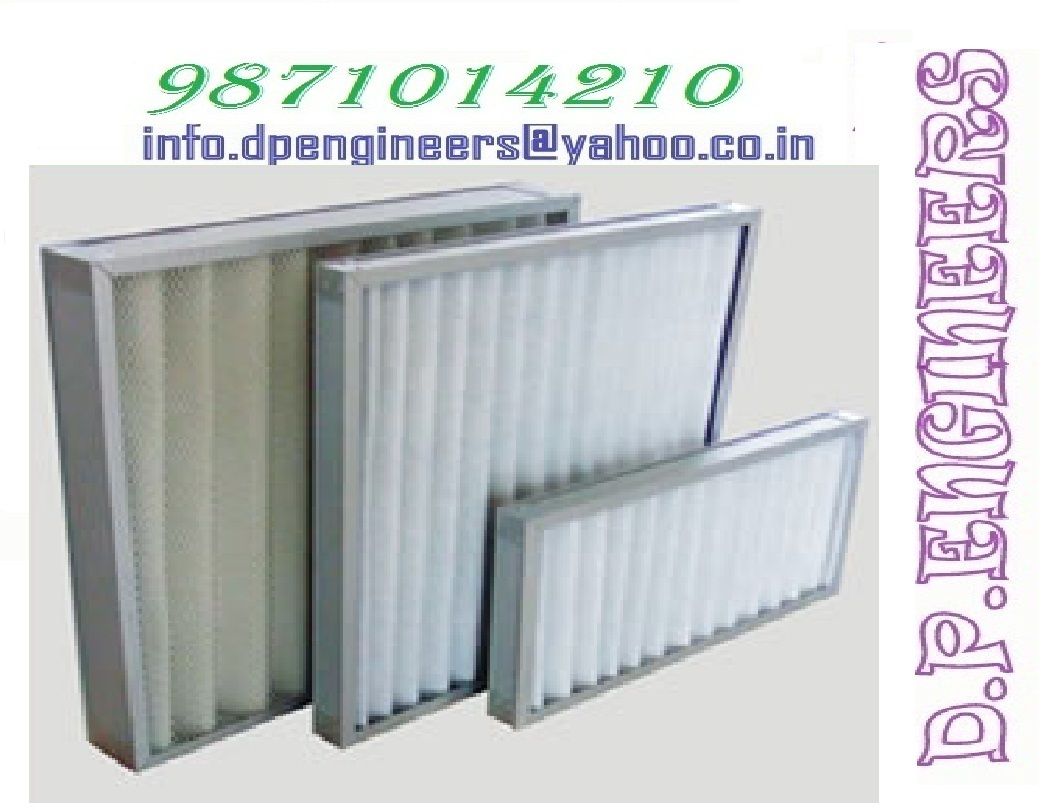

Pre Filters Specification

- Filtration Grade

- G4

- Flow Rate

- 500-3000 CFM

- Filter Type

- Air Pre Filter

- Media Type

- Washable Media

- Cleaning Method

- Manual Washing

- Capacity

- Depends on filter size and model

- Connecting Type

- Flange or Gasketed

- Efficiency (%)

- 80-90%

- Pressure

- Initial Pressure Drop: 10-30 mm WC

- Temperature Range

- Up to 120C

- Condition

- New

- Material

- Galvanized Iron, Stainless Steel Frame

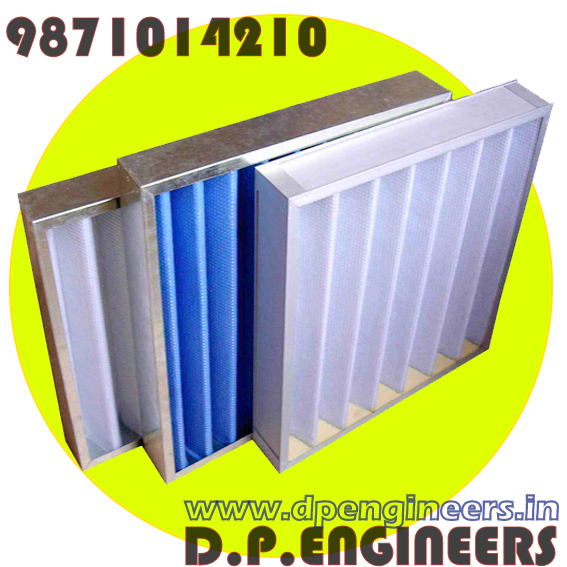

- Mesh

- Aluminum, Stainless Steel, Synthetic

- Diameter

- Standard sizes, Custom sizes available

- Construction

- Rugged Frame with Multi-layer Mesh

- Medium Filter

- Synthetic Media / Aluminum Mesh

- Weight

- Varies as per model, Approx. 1-5 kg

- Shape

- Rectangular

- Feature

- High dust holding capacity, Easily washable, Longer service life

Pre Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Pre Filters

Pre Filter

We are introducing a wide range of Pre Filter. Offered in varied sizes and specifications as per the application requirements of our clients, this filter is manufactured using superior quality raw material and employing contemporary technology. In addition,our quality examiner conduct a series of test on this range in order to eradicate any kind of defect in it.

Features:

- High dust holding capacity

- Low maintenance

- Durability

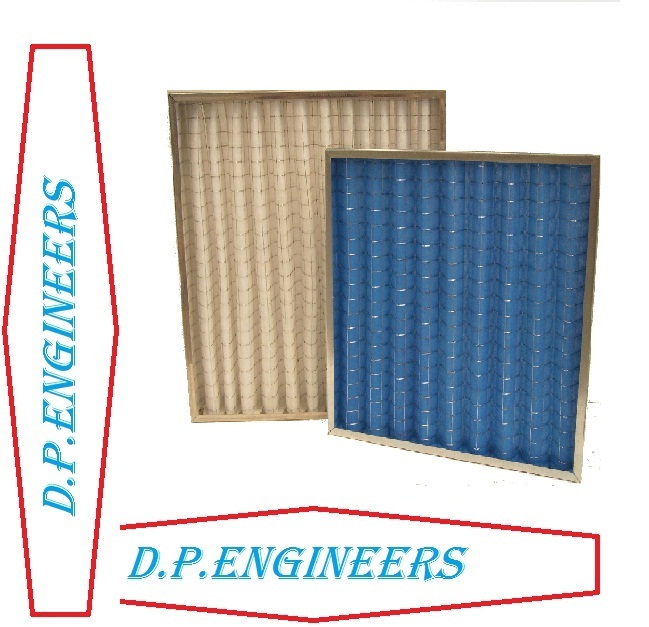

Application | Pre filters are most suited for: Air handling units (ahus), air-conditioning systems, power plants, chemical and fertilizer complexes, green houses, automatic drain holes, paint shops, textile mills, cement factories, laminar air flow units, bio safety hoods, fan filter units (ffu), gas turbine industry, compressor, diesel engines, nuclear power station, cd-rom production industry, picture tube production industry, semi-conductor industry, aeronautical industry and miscellaneous |

Versatile and Durable Design

Our pre filters are built with multi-layered mesh, available in synthetic, aluminum, or stainless steel, and reinforced with a rugged frame. Standard and custom sizes ensure compatibility with diverse HVAC and dust collection systems. Their corrosion-resistant construction and adaptability for both panel mounting and flange or gasketed connections make these filters suitable for industrial and commercial environments alike.

Efficient Filtration for Healthier Air

Certified to ISO 16890 and equipped with G4-grade medium, these pre filters achieve an impressive 80-90% efficiency rate. By efficiently capturing coarse particulates, the filters protect downstream equipment and improve indoor air quality. Their high dust holding capacity extends operational intervals between maintenance, reducing downtime while maintaining consistent airflow rates from 500 to 3000 CFM.

FAQs of Pre Filters:

Q: How often should I replace or clean these pre filters?

A: It is recommended to inspect and clean the filters every 3-6 months, depending on usage and environmental conditions. Proper cleaning extends the service life to between 2-3 years, subject to your systems operating environment.Q: What applications are these pre filters suitable for?

A: These filters are ideal for HVAC systems, industrial air handling units, and dust collection equipment, particularly where high humidity resistance and robust construction are essential. They conform to ISO 16890 standards, making them suitable for demanding industrial and commercial sectors.Q: What materials are used in the construction of the filters?

A: The frame is fabricated from galvanized iron or stainless steel in a silver/natural finish, while the mesh can be synthetic, aluminum, or stainless steel. This combination offers excellent corrosion resistance and a rugged structure for durability.Q: How do I clean and maintain the pre filters?

A: The filters are designed for manual washing. Remove the filter from its panel mounting, gently wash the media with water or mild detergent, and ensure it is fully dry before reinserting. This process helps maintain peak performance and prolongs filter life.Q: Where can I use custom-sized pre filters?

A: Custom sizes are available to fit unique or specialized air handling units, dust collectors, or HVAC systems where standard sizes may not be compatible. Contact your supplier to specify the required dimensions and media type.Q: What benefits do these pre filters offer?

A: Key benefits include high dust holding capacity, easy washability, long service life, and effective protection for downstream equipment. Their robust design and efficiency promote cleaner air, reduce maintenance needs, and support system longevity.Q: What is the maximum humidity and temperature resistance of the filter?

A: These pre filters can reliably operate in up to 100% humidity environments and withstand temperatures up to 120C, making them well-suited for challenging conditions in industrial and commercial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Filter Category

Dry Fabric Panel Type Air Filters

Temperature Range : Up to 80C

Diameter : Not Applicable (Panel Type)

Connecting Type : Other, Flange/slidein type

Efficiency (%) : 60% 90% (ASHRAE)

Material : Galvanized iron frame with synthetic nonwoven dry fabric filter media

Pressure : Initial pressure drop: 2035 Pa

PRE FILTERS Pleated Type

Temperature Range : Up to 80C

Diameter : Customizable as per application

Connecting Type : Other, Flange or gasket seal

Efficiency (%) : 90% for particles >10 micron

Material : Nonwoven synthetic media, galvanized steel frame

Pressure : Initial: <25 Pa

Microvee Type Fine Filter

Temperature Range : Up to 80C

Diameter : Custom as per requirement

Connecting Type : Other, Flange / Custom mount

Efficiency (%) : 90 95% (approx) for 5 micron

Material : Galvanized steel / Aluminium / Stainless Steel frame, microfine synthetic fiber media

Pressure : Initial Pressure Drop: 24 mm WG (max 50 mm WG)

Pleated Pre Filters

Temperature Range : Up to 80C

Diameter : Customizable as per requirement

Connecting Type : Other, Flanged or Casement

Efficiency (%) : 8090% for particles 5 micron

Material : Galvanized iron, Aluminium, Synthetic Media

Pressure : Initial: 1525 Pa, Final: up to 250 Pa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS