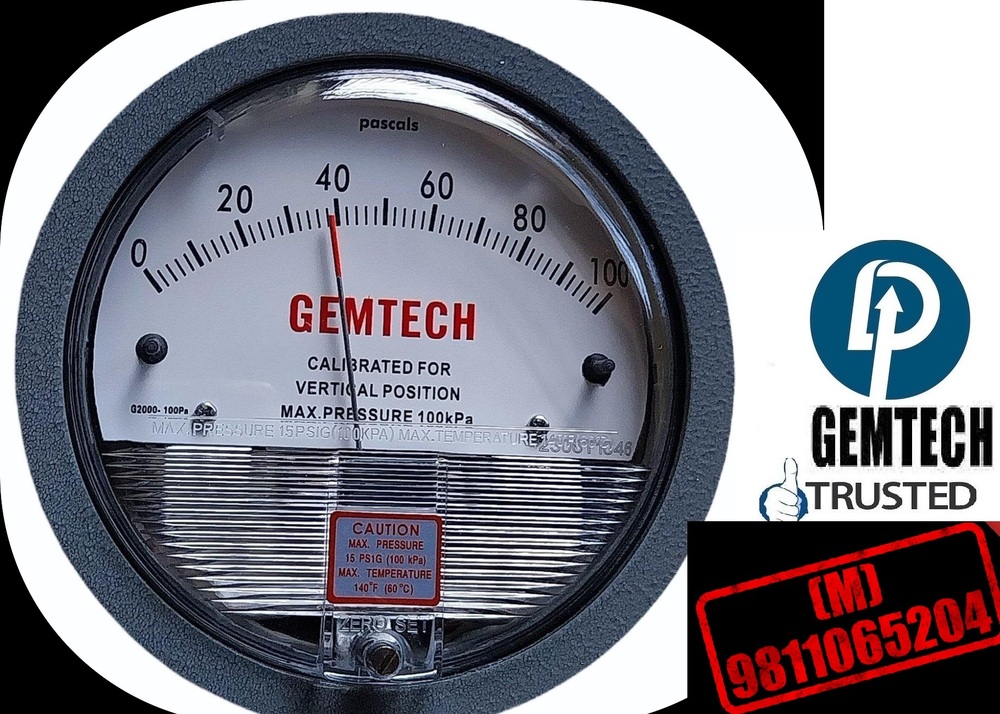

Pharmaceutical GEMTECH Differential Pressure Gauge in Yadgir Karnataka

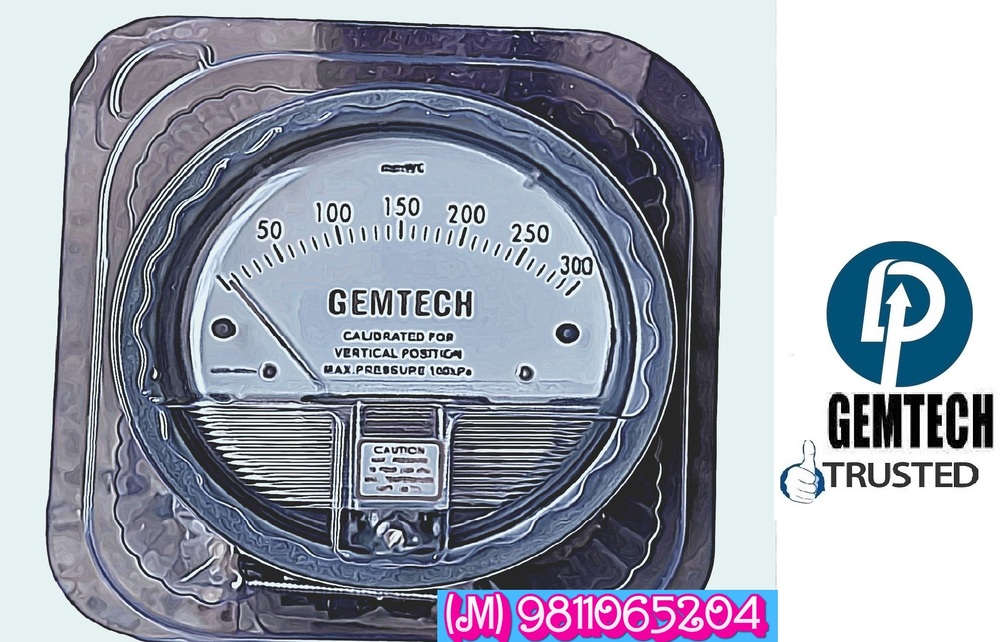

Pharmaceutical GEMTECH Differential Pressure Gauge in Yadgir Karnataka Specification

- Thread

- 1/8 BSP

- Sensor Type

- Diaphragm Type Differential Sensor

- Display

- Analog (Dial Type)

- Outer Size

- 150 mm Diameter

- Seal Material

- Neoprene / Buna-N

- Grade

- Pharmaceutical

- Bourdon Tube

- Not Required (Diaphragm Type Mechanism)

- Material

- Stainless Steel (SS304/SS316)

- Dial Material

- Aluminum, White background with black marking

- Pointer Material

- Aluminum, Black

- Processing Type

- CNC precision engineered

- Diameter

- 150 mm

- Glass Size

- Full View, toughened glass

- Mount Type

- Surface/Panel Mount

- Scale Range

- 0-25 mmWC to 0-1000 mmWC

- Accuracy

- 2% of FSD

- Finishing

- Matt/Glossy Finish

- Measure Pressure Of

- Gas and air

- Accessories

- Mounting Bracket, Process Connection Fittings

Pharmaceutical GEMTECH Differential Pressure Gauge in Yadgir Karnataka Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- Delhi

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Packaging Details

- E-mail : dpsharma74@yahoo.co.in, dpsharma1974@gmail.com, dpsharma949@gmail.com Mr D.P.SHARMA 9871014210 WhatsApp number :9871014210,9268631221 Websites : www.dpengineers.in, www.dpengineer.in, www.dpengineers.co.in, www.dpengineer.co.in, www.dpengineersindia.com, www.dpengineerindia.com, www.dpengineersindia.in, www.dpengineers.info, www.dpengineer.info, www.dp-engineers.com, www.dpengineerindia.in, www.dpengineersindia.net, www.dpengineersdelhi.co.in, www.dpengineersdelhi.com, www.dp-engineers.co.in, www.dpengineersdelhi.net, https://www.exportersindia.com/dpengineers

- Main Export Market(s)

- Asia, Middle East

- Main Domestic Market

- Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand

About Pharmaceutical GEMTECH Differential Pressure Gauge in Yadgir Karnataka

Pharmaceutical GEMTECH Differential Pressure Gauge in Yadgir Karnataka

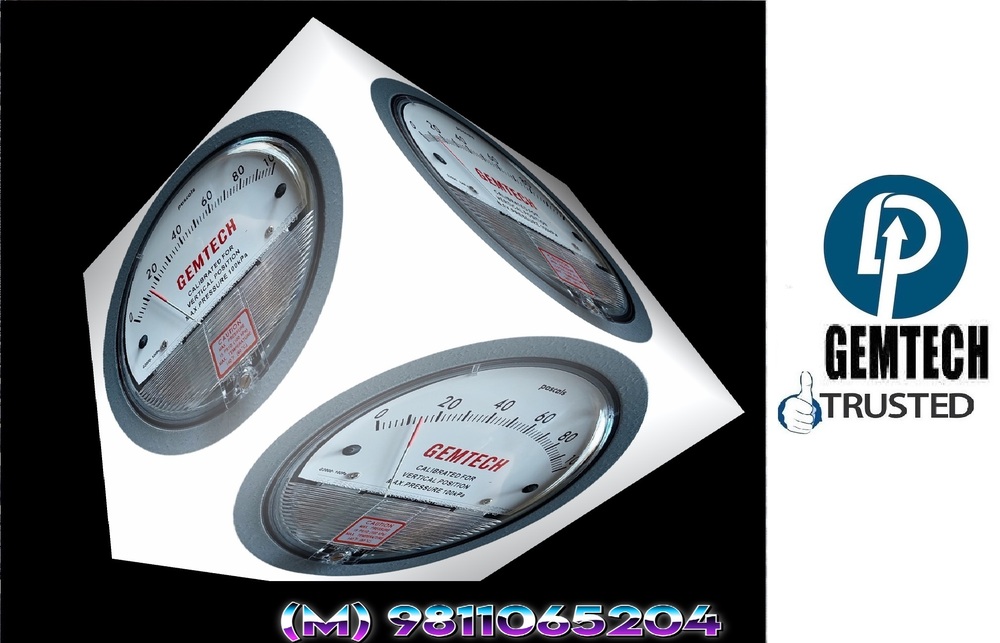

Series G2000 GEMTECH Differential Pressure Gauges are Widely Utilized For Measuring Pressure of Fan And Blowing Machine, resistance of Filter,Wind Speed, Furnace Pressure, Differential Pressure Of Pore Plate,The Pressure of drum water level, Liquid Amplifier And Hydraulic Pressure System. Meantime,They Are Used To Control The Automatic Valve And Specific Value Of Air-Producer Gas In Combustion And They Are Used To Test Blood Pressure And Respiratory Pressure In Medical Health Care Equipment. There Are More Than 81 Models To Suit Your Needs Precisely.The Key Components Adopt Import Materials.SPECIFICATION

- Ambient Temperature - -21 ~140 -6 ~60

- Rated Pressure -20 inHg~30 inHg (-68~103KPa)

- Overpressure - Protective rubber stopper will be blown out if rated pressure is up to about 50.8 inHg (172KPa)

- Process Connections - 1/8" female NPT duplicate high and low pressure taps - one pair side and one pair back

- Housing - Die cast aluminum case and bezel, with acrylic cover, Exterior finish is coated gray to withstand 168 Hour Salt Spray Corrosion Test

- Accuracy - A2% of full span at 70(21(A3% on -0, and A4% on -00)

- Range -20 inHg~38 inHg (-68KPa~130KPa)(Special Specification also can be ordered.)

FEATURES

FEATURES- OEM/ODM

- There Is No Need To Fill Liquid To Gauge.

- The Gauge Can Measure Positive Pressure,Negative Pressure And Differential Pressure.

- It Will Be Easy To Install And Measure In Different Ways Because Of Two Groups Of Ports Which Can Measure Positive And Negative Pressure.

- To Eliminate The Friction From The Movement Of Gear Wheel By The Mechanism Of Magnetic Magnet Feed.

- Exact And Stable Fixed Position Of Needle.

- The Gauge Has Great Antiknock Characteristics.

- There Are 81 Types Of Ranges.Minimum is 0-60 Pa And Maximum is 0-21-KPa

- Filter Monitoring

- Air Velocity With Pitot Tube

- Blower Vacuum Monitoring

- Fan Pressure Indication

- Duct,Room or Building Pressures

- Clean Room Positive Pressure Indication

GEMTECH By Model Number Popularity

- FILTER BY

- Range - MM Of Water

| Model | Description |

|---|---|

| G2000-100MM | DPG,Range 0-100 MM W.C., Minor Divisions 2.0. |

| G2000-10MM | DPG,Range 0-10 MM W.C.,Minor Divisions .20,Calibrated For Vertical Scale Position. |

| G2000-150MM | DPG,Range 0-150 MM W.C. |

| G2000-15MM | DPG,Range 0-15 MM W.C. |

| G2000-200MM | DPG,Range 0-200 MM W.C. |

| G2000-250MM | DPG,Range 0-250 MM W.C. |

| G2000-25MM | DPG,Range 0-25 MM W.C. Minor Divisions .50. |

| G2000-300MM | DPG,Range 0-300 MM W.C. |

| G2000-50MM | DPG,Range 0-50 MM W.C., Minor Divisions 1.0. |

| G2000-6MM | DPG,Range 0-6 MM W.C., Minor Divisions .20, Calibrated For Vertical Scale Position. |

| G2000-80MM | DPG,Range 0-80 MM W.C., Minor Divisions 2.0. |

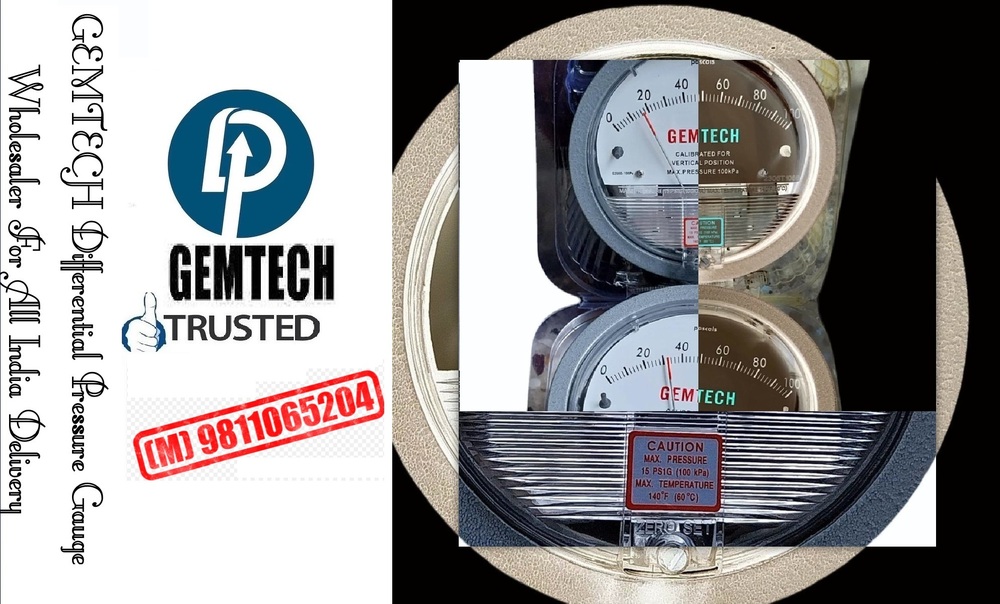

Precision Monitoring for Clean Room Standards

Engineered specifically for sensitive clean room and pharmaceutical settings, the GEMTECH Differential Pressure Gauge provides accurate, real-time readings of differential pressure across processes. Its robust diaphragm sensor and toughened full-view glass guarantee both durability and precision. The analog dial display with 2% FSD accuracy and a wide scale range makes it indispensable for stringent monitoring environments.

Durable Construction and Versatile Installation

CNC precision manufacturing using SS304/SS316 ensures longevity and high performance, even in harsh conditions. The gauge can be mounted on panels or surfaces and is supplied with mounting brackets and process connection fittings. With IP65-rated enclosure protection, it is well suited for Indian pharmaceutical industries, laboratories, and HVAC systems.

FAQ's of Pharmaceutical GEMTECH Differential Pressure Gauge in Yadgir Karnataka:

Q: How do I install the GEMTECH Differential Pressure Gauge in my facility?

A: Installation can be on either a panel or surface using the provided mounting bracket and process connection fittings. Choose either back or bottom connection types (1/8 BSP thread) as required for your setup. The full-view, 150 mm diameter dial ensures easy readability in clean rooms, HVAC units, or laminar air flow cabinets.Q: What makes this gauge suitable for clean room and pharmaceutical environments?

A: GEMTECH's gauge is built with a diaphragm-type differential pressure sensor that avoids the need for a bourdon tube, ensuring better reliability and sensitivity for low-range pressure measurement. Its stainless steel construction, IP65 enclosure, and compliance with cGMP and ISO standards make it ideal for regulated environments.Q: When is zero adjustment necessary, and how can it be performed?

A: Zero adjustment should be done when the system is at rest to ensure accurate baseline readings. This gauge is equipped with an external adjustment knob for straightforward recalibration without disassembly, making the process quick and user-friendly.Q: Where can this pressure gauge be used effectively?

A: This differential pressure gauge is designed for use in pharmaceutical clean rooms, HVAC systems, laminar air flow cabinets, and all applications where monitoring air or gas pressure differentials is crucial. Its robust build and immediate mechanical response make it highly versatile.Q: What benefits does the diaphragm-type sensor offer over traditional designs?

A: The diaphragm-type mechanism enhances sensitivity and response time, providing immediate accuracy for low differential pressures. This design also increases durability and reduces maintenance compared to gauges that use bourdon tubes.Q: How does the gauge ensure accuracy and reliability?

A: Featuring a CNC-engineered mechanism, the gauge delivers 2% of FSD accuracy and quick mechanical response. Its toughened full-view glass and precision dial with high-contrast markings foster reliable, clear readings, even in demanding pharmaceutical and clean room settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Best Supplier GEMTECH Differential Pressure Gauge | D.P.ENGINEERS DELHI Category

GEMTECH Differential Pressure Gauge Distributor For Kalol Gujarat

Price 4500 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel

Mount Type : Back

Processing Type : Standard

Diameter : 4 inch / 100 Millimeter (mm)

GEMTECH INDIA KA NAYA DIFFERENTIAL PRESSURE GAUGE

Minimum Order Quantity : 5 Pieces

Material : Stainless Steel

Mount Type : Back

Processing Type : Standard

Diameter : 4 inch / 100 Millimeter (mm)

GEMTECH Differential Pressure Gauge By Noida Uttar Pradesh

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel

Mount Type : Back

Processing Type : Standard

Diameter : 4 inch / 100 Millimeter (mm)

Series G2000 GEMTECH Differential Pressure Gauge By SIDCUL Rudrapur Uttarakhand

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel

Mount Type : Back

Processing Type : Standard

Diameter : 4 inch / 100 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS